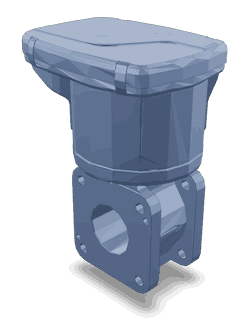

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3648212 Fuel Flow Valve is a component designed for use in commercial trucks. It plays a role in regulating the flow of fuel within the engine system, contributing to the overall efficiency and performance of the vehicle. Understanding its function and significance is important for maintaining and optimizing truck operations.

Basic Concepts of Fuel Flow Valves

A Fuel Flow Valve is a device that controls the amount of fuel that passes through the fuel system to the engine. It operates by adjusting the flow rate based on the engine’s demand, ensuring that the correct amount of fuel is delivered under varying conditions. This component is integral to the fuel system, as it helps maintain the proper fuel-to-air ratio, which is vital for efficient combustion and engine performance 1.

Purpose of the Cummins 3648212 Fuel Flow Valve

The Cummins 3648212 Fuel Flow Valve is specifically designed to regulate fuel flow in Cummins engines. It functions within the fuel delivery system to ensure that fuel is delivered at the optimal rate and pressure, supporting consistent engine operation. This valve helps in managing fuel distribution, which is crucial for the engine’s performance and efficiency.

Key Features

The Cummins 3648212 Fuel Flow Valve is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and reliability in demanding commercial truck applications. The valve is engineered to withstand the pressures and temperatures encountered in diesel fuel systems, ensuring long-term performance 2.

Benefits

The Cummins 3648212 Fuel Flow Valve offers several benefits, including improved fuel efficiency and enhanced engine performance. By precisely controlling fuel flow, it helps in achieving better combustion, which can lead to increased power output and reduced fuel consumption. Additionally, its reliable operation contributes to the overall dependability of the truck’s fuel system.

Installation and Integration

Installing the Cummins 3648212 Fuel Flow Valve involves integrating it into the truck’s fuel system according to the manufacturer’s guidelines. This process may require specific tools and knowledge of the fuel system’s components. It is important to ensure that all connections are secure and that the valve is properly aligned to function correctly within the system.

Common Issues and Troubleshooting

Common issues with the Cummins 3648212 Fuel Flow Valve may include leaks, blockages, or malfunctions due to wear and tear. Troubleshooting these problems often involves checking for proper installation, inspecting for damage, and ensuring that the valve is operating within its specified parameters. Regular maintenance can help prevent many of these issues.

Maintenance Tips

To maintain the Cummins 3648212 Fuel Flow Valve, it is recommended to perform regular inspections and cleaning. This includes checking for any signs of wear, ensuring that all connections are tight, and cleaning the valve as necessary to remove any buildup that could affect its operation. Adhering to a maintenance schedule can help ensure the valve’s optimal performance and longevity.

Performance Enhancements

The Cummins 3648212 Fuel Flow Valve contributes to overall truck performance by ensuring that fuel is delivered efficiently to the engine. This can lead to improvements in fuel economy and engine responsiveness, as the engine receives the precise amount of fuel needed for optimal operation under various driving conditions.

Safety Considerations

When installing, operating, or maintaining the Cummins 3648212 Fuel Flow Valve, it is important to follow safety guidelines. This includes working in a well-ventilated area, using the appropriate personal protective equipment, and ensuring that the fuel system is depressurized before performing any maintenance or repairs. Adhering to these safety practices helps protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient engine components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position in the industry.

Cummins Fuel Flow Valve 3648212 Compatibility

The Cummins Fuel Flow Valve, part number 3648212, is a critical component in the fuel management systems of several Cummins engines. This valve is designed to regulate the flow of fuel to the engine, ensuring optimal performance and efficiency. It is compatible with a range of Cummins engines, including the QSK60, G CM2358, and K110 models.

QSK60 and G CM2358

The QSK60 and G CM2358 engines are part of Cummins’ heavy-duty diesel engine lineup, often used in marine and industrial applications. The 3648212 Fuel Flow Valve is engineered to fit seamlessly into the fuel systems of these engines, providing precise control over fuel delivery. This ensures that the engines operate at peak efficiency, reducing fuel consumption and emissions.

K110

The K110 engine, another member of Cummins’ robust engine family, also benefits from the 3648212 Fuel Flow Valve. This valve is designed to integrate smoothly with the K110’s fuel management system, enhancing the engine’s performance and reliability. Its precise control over fuel flow helps maintain consistent power output and improves overall engine longevity.

Grouping for Efficiency

The compatibility of the 3648212 Fuel Flow Valve across the QSK60, G CM2358, and K110 engines allows for streamlined maintenance and inventory management. Technicians and operators can use the same part across multiple engine types, simplifying the process of sourcing and installing components. This not only reduces downtime but also ensures that the engines continue to operate efficiently and reliably.

Role of Part 3648212 Fuel Flow Valve in Engine Systems

The part 3648212 Fuel Flow Valve is an integral component in the orchestration of fuel delivery within engine systems. Its primary function is to regulate the flow of fuel from the fuel control module to the combustion chambers, ensuring that the engine receives the precise amount of fuel required for optimal performance under varying operational conditions.

Integration with the Fuel Control Module

The Fuel Flow Valve works in tandem with the Fuel Control Module (FCM), which is responsible for monitoring and adjusting fuel delivery based on engine demand, ambient conditions, and other operational parameters. The FCM sends signals to the Fuel Flow Valve to open or close to varying degrees, thereby controlling the volume of fuel that passes through. This dynamic adjustment is essential for maintaining the correct air-fuel ratio, which is vital for efficient combustion and overall engine performance 3.

Interaction with the Module

Within the broader context of the engine’s fuel system, the Module plays a significant role in interpreting data from various sensors throughout the engine. It processes this data to make real-time adjustments to fuel delivery. The Fuel Flow Valve responds to these adjustments by modulating the fuel flow, ensuring that the engine operates within its designed parameters regardless of the load or speed.

Fuel Control Dynamics

The Fuel Control system, as a whole, relies on the precise operation of the Fuel Flow Valve to maintain stability and efficiency. By regulating fuel flow, the valve helps to prevent issues such as fuel starvation or over-fueling, both of which can lead to decreased performance and increased emissions. The valve’s ability to respond quickly to changes in engine demand is a key factor in the overall responsiveness and efficiency of the Fuel Control system.

Conclusion

The Cummins 3648212 Fuel Flow Valve is a key player in the intricate dance of fuel management within engine systems. Its seamless integration with the Fuel Control Module and the Module ensures that the engine receives the exact amount of fuel needed for each moment of operation, contributing to the engine’s reliability, performance, and efficiency.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Charging the Internal Combustion Engine, Springer, 2010.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.