The Cummins 3640100 Fuel Pump is a component designed for use in heavy-duty trucks. It plays a role in the operation of these vehicles by ensuring that fuel is delivered efficiently to the engine. This part is part of Cummins Inc.’s lineup of fuel system components, which are known for their reliability and performance in demanding applications 1.

Basic Concepts of Fuel Pumps

A fuel pump is a device that moves fuel from the tank to the engine. It operates by creating pressure that pushes the fuel through the lines and into the engine’s fuel system. In the context of a truck, the fuel pump is a vital part of the fuel delivery system, ensuring that the engine receives the necessary fuel to operate under various conditions 2.

Purpose of the Cummins 3640100 Fuel Pump

This Cummins part is designed to provide consistent and reliable fuel delivery to the engine of a heavy-duty truck. It ensures that the engine receives the correct amount of fuel at the right pressure, which is important for optimal performance and efficiency. This pump helps maintain the engine’s power output and fuel economy by delivering fuel precisely when and where it is needed 3.

Key Features

The Cummins 3640100 Fuel Pump is characterized by its robust design and the use of high-quality materials. It is built to withstand the rigors of heavy-duty truck applications. The pump incorporates advanced technological features that enhance its performance and durability. These features include precision engineering and the use of materials that resist wear and corrosion 4.

Benefits

Using the Cummins 3640100 Fuel Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in an optimal manner. The pump’s reliable operation helps maintain consistent engine performance. Additionally, its design and construction support long-term durability, reducing the need for frequent replacements 5.

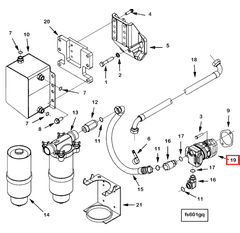

Installation and Integration

Installing the Cummins 3640100 Fuel Pump involves integrating it into the truck’s fuel system. This process requires attention to specific requirements and considerations to ensure proper function. The pump must be correctly positioned and connected to the fuel lines and electrical system to operate effectively 6.

Troubleshooting Common Issues

Common issues with the Cummins 3640100 Fuel Pump may include fuel delivery problems or pump failures. Identifying these issues often involves checking for signs such as engine misfires or a decrease in performance. Resolving these problems may require inspecting the pump and its connections, or in some cases, replacing the pump 7.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3640100 Fuel Pump, regular maintenance is recommended. This includes performing routine checks and adhering to service intervals. Keeping the fuel system clean and free of contaminants can also help maintain the pump’s efficiency 8.

Performance Under Various Conditions

The Cummins 3640100 Fuel Pump is designed to perform under a range of operating conditions. It is capable of maintaining efficient fuel delivery in varying temperatures and under different load conditions. This adaptability ensures that the engine continues to operate smoothly regardless of the external environment 9.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, with a strong reputation for manufacturing high-quality engine components, including fuel pumps. The company has a history of innovation and commitment to providing reliable products for various applications, particularly in the heavy-duty truck sector 10.

Compatibility

The Cummins Fuel Pump part number 3640100 is a component in ensuring the efficient operation of the engines it is designed to fit. This part is engineered to work seamlessly with several Cummins engine models, providing reliable fuel delivery and maintaining engine performance.

QSK38 CM2150 MCRS and QSK50 CM2150 MCRS

The Cummins Fuel Pump 3640100 is compatible with both the QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines. These engines are part of the Cummins QSK series, known for their robust design and high performance in various applications. The fuel pump ensures that the fuel is delivered at the correct pressure and flow rate, which is important for the optimal combustion process in these engines.

QSK50 CM2350 K108

Similarly, the Cummins Fuel Pump 3640100 is also compatible with the QSK50 CM2350 K108 engine. This engine is another variant in the Cummins QSK series, designed for demanding applications that require high power and reliability. The fuel pump’s role in this engine is to maintain the fuel supply under varying operational conditions, ensuring consistent engine performance and efficiency.

Installation and Functionality

While the specific installation details may vary slightly between engine models, the Cummins Fuel Pump 3640100 is designed to integrate smoothly into the fuel systems of the QSK38 CM2150 MCRS, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. Proper installation is crucial to ensure that the fuel pump operates effectively and prolongs the lifespan of the engine components. Technicians should follow the manufacturer’s guidelines for installation and maintenance to ensure the best performance and reliability.

Role of Part 3640100 Fuel Pump in Engine Systems

The part 3640100 Fuel Pump is a component in the fuel delivery system of an engine. Its primary function is to ensure a consistent and adequate supply of fuel to the engine’s combustion chambers. Here’s how it integrates with various engine components:

Fuel Transfer Pump

The fuel transfer pump works in conjunction with the part 3640100 Fuel Pump to maintain fuel pressure and flow. The transfer pump moves fuel from the tank to the high-pressure pump, ensuring that the Fuel Pump receives a steady supply of fuel. This collaboration is vital for maintaining optimal fuel pressure, which is necessary for efficient engine performance. The transfer pump also helps in reducing the workload on the Fuel Pump, thereby enhancing its longevity and reliability.

Fuel Injectors

Once the Fuel Pump pressurizes the fuel, it is delivered to the fuel injectors. The injectors rely on the consistent pressure provided by the Fuel Pump to atomize the fuel properly. This fine mist of fuel ensures better combustion efficiency and power output. The Fuel Pump’s role here is to maintain the necessary pressure to support the injectors’ operation, ensuring they deliver fuel at the right time and in the right quantity.

Fuel Filter

The Fuel Pump also plays a role in the fuel filtration process. Before the fuel reaches the injectors, it passes through the fuel filter, which removes impurities and contaminants. The Fuel Pump must provide enough pressure to push the fuel through the filter without causing excessive strain. This ensures that the fuel delivered to the injectors is clean, which is essential for preventing wear and maintaining engine efficiency.

Fuel Rail

In engines equipped with a fuel rail, the Fuel Pump supplies pressurized fuel to this component. The fuel rail distributes the fuel to each injector, ensuring uniform pressure across all cylinders. The Fuel Pump’s consistent pressure output is crucial for the fuel rail’s function, as it ensures that each injector receives the same amount of fuel, leading to balanced combustion and smooth engine operation.

Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various engine parameters, including fuel pressure. The Fuel Pump’s performance directly impacts the data the ECU receives. A well-functioning Fuel Pump ensures that the ECU can make accurate adjustments to fuel delivery, optimizing engine performance and fuel efficiency. The ECU may also send signals to the Fuel Pump to adjust its output based on driving conditions, further highlighting the pump’s importance in the engine’s overall control system.

Conclusion

The Cummins 3640100 Fuel Pump is a critical component in the fuel delivery system of heavy-duty trucks. Its robust design, advanced features, and compatibility with various Cummins engine models make it a reliable choice for ensuring efficient and consistent fuel delivery. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing its performance and longevity.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩ -

Berns, Karsten et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩ -

Berns, Karsten et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Berns, Karsten et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.