This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

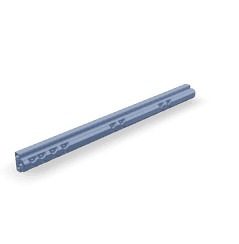

The Cummins 3638060 Fuel Manifold is a critical component designed for use in heavy-duty trucks. It plays a significant role in the fuel delivery system, ensuring efficient distribution of fuel to the injectors. This part is essential for maintaining the performance and reliability of the truck’s engine under various operating conditions.

Purpose and Function

The Cummins 3638060 Fuel Manifold operates within the fuel delivery system to facilitate the distribution of fuel to the injectors. It acts as a junction point where fuel from the supply line is directed to multiple injectors, ensuring each receives the necessary amount of fuel for combustion. This even distribution is vital for consistent engine performance and efficiency 1.

Key Features

The Cummins 3638060 Fuel Manifold is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to the corrosive effects of fuel and the high pressures within the fuel system. The manifold is engineered to withstand the demanding conditions typical of heavy-duty truck operations, ensuring long-term reliability 2.

Benefits

The Cummins 3638060 Fuel Manifold offers several advantages. It provides improved fuel distribution, which contributes to enhanced engine performance. The manifold’s design ensures that fuel is delivered consistently to each injector, promoting efficient combustion and reducing the likelihood of engine misfires. Additionally, its robust construction ensures reliability even under demanding conditions, contributing to the overall durability of the truck’s engine system 3.

Installation and Integration

Proper installation of the Cummins 3638060 Fuel Manifold is crucial for its effective operation. The installation process involves aligning the manifold with the fuel supply line and securing it in place to ensure a tight fit. Correct alignment and secure fitting are important to prevent fuel leaks and ensure optimal fuel distribution. Following manufacturer guidelines during installation is recommended to maintain the integrity of the fuel system 4.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3638060 Fuel Manifold is important to ensure its continued performance. This includes routine inspections for signs of wear or damage, cleaning to remove any deposits that may accumulate, and checking for proper alignment and secure fitting. Common issues may include fuel leaks or inconsistent fuel distribution, which can often be traced back to improper installation or wear on the manifold. Troubleshooting these issues typically involves inspecting the manifold for damage, ensuring all connections are secure, and cleaning or replacing the manifold as necessary 5.

Safety Considerations

When working with the Cummins 3638060 Fuel Manifold, it is important to observe safety protocols. This includes handling the fuel system with care to avoid spills and ensuring that all work is conducted in a well-ventilated area. Adherence to manufacturer guidelines for installation, maintenance, and troubleshooting is important to ensure safety and maintain the performance of the fuel system 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a leader in the automotive and heavy-duty truck industry. The company is committed to innovation and quality in manufacturing, consistently delivering products that meet the demanding requirements of its customers. Cummins’ focus on research and development ensures that its products, including the Cummins 3638060 Fuel Manifold, are at the forefront of technology and performance in the industry 7.

Conclusion

The Cummins 3638060 Fuel Manifold is a vital component in the fuel delivery system of heavy-duty trucks. Its role in ensuring efficient fuel distribution to the injectors contributes significantly to the engine’s performance and reliability. With its robust design and key features, this part is well-suited to withstand the demanding conditions of heavy-duty truck operations, providing long-term reliability and enhanced engine performance.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

Modern Diesel Technology Preventive Maintenance and Inspection, John Dixon, Delmar Cengage Learning, 2010.

↩ -

Introduction to Engine Valvetrains, Yushu Wang, SAE International, 2007.

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022.

↩ -

QSK60G (Single Turbocharger) Hot Start Fast Ramp Generator Set Applications, Bulletin Number 4388868, Operation and Maintenance Manual.

↩ -

Modern Diesel Technology Preventive Maintenance and Inspection, John Dixon, Delmar Cengage Learning, 2010.

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.