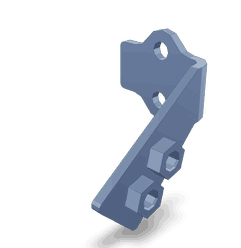

3635859

Fuel Plumbing Bracket

Cummins®

AVAILABLE

10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3635859 Fuel Plumbing Bracket is a component designed to facilitate the secure and organized routing of fuel lines in heavy-duty trucks. Its role is significant in maintaining the integrity and efficiency of the fuel delivery system, ensuring that fuel is transported safely and effectively from the tank to the engine 1.

Purpose and Function

The Fuel Plumbing Bracket serves to anchor and arrange the fuel lines within the truck’s fuel system. By providing a structured pathway for the fuel lines, it helps to prevent tangling and potential damage to the lines, which could otherwise lead to fuel leaks or inefficient fuel delivery. This organization is vital for maintaining consistent fuel pressure and flow, which are necessary for optimal engine performance 2.

Key Features

This Cummins part is constructed with durability and longevity in mind. It is made from materials that offer resistance to corrosion, which is particularly important in the harsh environments often encountered by heavy-duty trucks. The design of the bracket ensures compatibility with various fuel systems, allowing for versatile application across different truck models 3.

Benefits

Incorporating the Fuel Plumbing Bracket into a truck’s fuel system can lead to several advantages. It contributes to the reliability of the fuel system by securing the lines and reducing the likelihood of leaks. This, in turn, can enhance the overall performance of the truck by ensuring a steady supply of fuel to the engine. Additionally, the bracket’s robust construction helps to protect the fuel lines from physical damage, further contributing to the system’s durability.

Installation and Compatibility

Proper installation of the Fuel Plumbing Bracket is key to its effective function. It is designed to be compatible with a range of Cummins engine models, and it may also fit other truck makes and models, depending on the specific fuel system configuration. When installing, it is important to follow the manufacturer’s instructions to ensure that the bracket is correctly positioned and that the fuel lines are properly secured.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Plumbing Bracket is recommended to ensure continued optimal performance. This includes checking for signs of wear or damage and ensuring that the fuel lines remain securely fastened. If issues such as fuel leaks or irregular engine performance arise, inspecting the bracket and the fuel lines for any signs of damage or improper installation can be a starting point for troubleshooting.

Safety Considerations

When working with the Fuel Plumbing Bracket and the fuel system, it is important to observe safety precautions. This includes ensuring that the engine is off and that there are no sources of ignition nearby when performing maintenance or repairs. Following manufacturer guidelines and industry best practices is crucial to maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a history of producing diesel engines and related components. The company has built a reputation for quality and reliability across various industries, including heavy-duty trucking. Cummins’ commitment to innovation and customer satisfaction has made it a preferred choice for engine and component solutions.

Role of Part 3635859 Fuel Plumbing Bracket in Engine Systems

The integration of the Fuel Plumbing Bracket (part 3635859) within engine systems is fundamental to maintaining the integrity and efficiency of fuel delivery. This component acts as a secure mounting point for the fuel supply plumbing, ensuring that the fuel lines are properly positioned and supported throughout the engine bay.

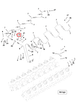

When considering the camshaft and gear, the Fuel Plumbing Bracket provides a stable foundation that allows for the precise routing of fuel lines. This is essential for minimizing fuel line vibrations, which can otherwise lead to wear and potential leaks. The bracket’s role becomes even more significant when paired with high-performance camshafts, where fuel delivery consistency is paramount for optimal engine performance.

In conjunction with the connecting rod and piston, the Fuel Plumbing Bracket supports the fuel lines that supply the injectors. This ensures that the fuel system can respond quickly to the demands of the engine, particularly during high-load scenarios where the connecting rod and piston are under significant stress. Proper fuel line management facilitated by the bracket helps maintain consistent fuel pressure, which is vital for the precise fuel injection timing required by modern engines.

For performance parts, the Fuel Plumbing Bracket is often a key component in custom fuel system installations. It allows for the secure attachment of aftermarket fuel lines and components, ensuring that the enhanced fuel delivery system is both safe and effective. This is particularly important in high-performance applications where the fuel system must be capable of delivering increased volumes of fuel without compromising safety or efficiency.

Conclusion

The Fuel Plumbing Bracket (part 3635859) plays a supportive yet essential role in the fuel system’s architecture. It ensures that the fuel supply plumbing is correctly positioned and secured, which is fundamental to the reliable operation of the engine, especially in performance-oriented applications.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.