3631977

Fuel Connector Adapter

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3631977 Fuel Connector Adapter is a critical component in the fuel systems of commercial trucks. It ensures a secure and efficient connection between various fuel lines and components, maintaining the integrity of the fuel delivery process from the tank to the engine.

Basic Concepts of Fuel Connector Adapters

A Fuel Connector Adapter acts as an intermediary piece that joins different sections of the fuel delivery system. It is essential for creating a leak-free and secure connection, which is vital for the efficient operation of the fuel system. Proper sealing and connection of fuel lines help maintain system pressure and prevent fuel leaks, which could lead to performance issues or safety hazards 1.

Purpose of the Cummins 3631977 Fuel Connector Adapter

This Cummins part is integral to the operation of a truck’s fuel system. It maintains fuel integrity by providing a reliable connection point that resists leaks and maintains system pressure. This ensures consistent fuel delivery to the engine, necessary for optimal performance and efficiency 2.

Key Features

The Cummins 3631977 is constructed from durable materials that resist the corrosive effects of fuel. Its design includes reinforced connection points and a robust housing, enhancing its longevity. The adapter may also feature a specialized sealing mechanism or compatibility with a wide range of fuel system components 3.

Benefits

Using the Cummins 3631977 offers several advantages. It improves fuel system reliability by ensuring secure connections that resist leaks. The adapter’s design facilitates ease of installation, reducing downtime during maintenance. Its durability and reliability may lead to cost savings by minimizing the need for frequent replacements or repairs.

Installation Process

Installing the Cummins 3631977 requires following specific steps to ensure a proper fit. The process involves preparing the fuel lines, aligning the adapter with the connection points, and securing it in place. Tools such as wrenches may be necessary to tighten connections to the manufacturer’s specifications. Best practices include checking for proper alignment and ensuring that all connections are tight to prevent leaks.

Common Issues and Troubleshooting

Fuel Connector Adapters, including the Cummins 3631977, may encounter issues such as leaks or connection failures. These problems can often be traced to improper installation, wear and tear, or compatibility issues with other fuel system components. Troubleshooting steps may involve inspecting the connections for signs of wear, ensuring that the adapter is correctly aligned and tightened, and verifying compatibility with the fuel system components in use.

Maintenance Tips

Regular maintenance of the Cummins 3631977 is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the adapter to remove any buildup that could affect its function, and tightening connections as needed. Adhering to recommended inspection intervals can help identify potential issues before they lead to more significant problems.

Safety Considerations

When working with fuel system components, including the Cummins 3631977, it is important to follow safety guidelines to prevent accidents. This involves working in a well-ventilated area, avoiding open flames or sparks near the fuel system, and wearing appropriate personal protective equipment. Compliance with industry standards and regulations is also crucial to ensure safe and effective operation of the fuel system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

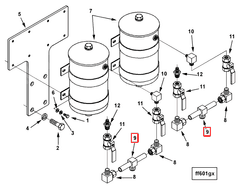

Role of Part 3631977 Fuel Connector Adapter in Engine Systems

The Cummins 3631977 Fuel Connector Adapter is integral to the seamless operation of various engine systems by ensuring secure and efficient connections between components.

In the context of accessories mounting, the adapter facilitates the attachment of auxiliary components to the fuel system, allowing for a stable and reliable connection that can withstand the dynamic conditions within the engine compartment.

When integrated into an engine kit, the adapter plays a key role in maintaining the integrity of the fuel delivery system. It ensures that fuel is efficiently transferred from the tank to the engine, minimizing the risk of leaks and ensuring consistent fuel pressure.

The filter and fuel filter systems benefit from the adapter by providing a secure connection point for the fuel lines. This ensures that the filtration process is not compromised, allowing for clean fuel to reach the engine and promoting optimal performance.

In a filter fuel kit, the adapter is used to connect various components, such as the filter housing and the fuel lines, ensuring that the filtration system operates efficiently and effectively.

The inlet fitting and outlet fitting of the fuel system are enhanced by the adapter, which provides a reliable connection that can handle the pressure and flow rates of the fuel. This is essential for maintaining the performance and longevity of the engine.

Finally, in the context of mounting components, the adapter ensures that all connections are secure and properly aligned, reducing the risk of vibration-induced disconnections and promoting a stable fuel delivery system.

Conclusion

The Cummins 3631977 Fuel Connector Adapter is a vital component in the fuel systems of commercial trucks, ensuring secure and efficient connections between various fuel lines and components. Its durable construction, ease of installation, and reliable performance contribute to the overall efficiency and safety of the fuel delivery system. Regular maintenance and adherence to safety guidelines are essential for maximizing the longevity and effectiveness of this adapter.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Willard W. Pulkrabek. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

John Dixon. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.