This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

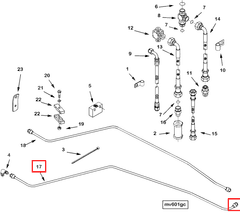

The Cummins 3630050 Fuel Supply Line is a component designed for use in heavy-duty trucks. It plays a role in the fuel system by ensuring the efficient transfer of fuel from the tank to the engine. This part is integral to maintaining the performance and reliability of the vehicle, contributing to its overall operational efficiency 1.

Purpose and Function

The Cummins 3630050 facilitates the transfer of fuel from the tank to the engine. It is positioned within the fuel system to provide a consistent and reliable flow of fuel, which is necessary for the engine to operate efficiently. This component ensures that the engine receives the necessary fuel supply under various driving conditions, thereby supporting the truck’s performance 2.

Key Features

The Cummins 3630050 is constructed using high-quality materials that enhance its durability and performance. It is designed to withstand the pressures and temperatures associated with heavy-duty truck operations. The line features a robust construction that resists wear and tear, ensuring long-lasting use. Additionally, it is engineered to maintain fuel integrity, preventing contamination and ensuring clean fuel delivery to the engine 3.

Benefits

Using the Cummins 3630050 offers several advantages. It contributes to improved fuel efficiency by ensuring a consistent and clean fuel supply to the engine. This component is also known for its reliability, reducing the likelihood of fuel system failures. Furthermore, its durable construction supports longevity, making it a cost-effective choice for heavy-duty truck applications 4.

Installation and Compatibility

Proper installation of the Cummins 3630050 is crucial for optimal performance. It is recommended to follow manufacturer guidelines to ensure correct fitting and secure connections. This component is designed to be compatible with various truck models, though specific installation requirements may vary. Adhering to these guidelines will help maintain the integrity of the fuel system and ensure efficient operation 1.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3630050 is important to ensure its continued performance. This includes periodic inspections for signs of wear, leaks, or damage. Common issues may include fuel leaks or reduced fuel flow, which can often be addressed through routine checks and timely repairs. Following best practices for maintenance will help prevent potential problems and extend the lifespan of the component 2.

Safety Considerations

When working with the Cummins 3630050, it is important to follow safety guidelines to prevent accidents and ensure personal safety. This includes proper handling procedures to avoid fuel spills and the use of appropriate protective equipment. Awareness of potential hazards, such as fuel ignition sources, is crucial. In case of emergencies, having a response plan in place can help mitigate risks and ensure a safe working environment 3.

Environmental Impact

The use of the Cummins 3630050 contributes to environmental considerations by supporting improved fuel efficiency and reduced emissions. Efficient fuel delivery helps minimize fuel consumption, which in turn lowers the carbon footprint of heavy-duty trucks. Additionally, the component’s design aims to prevent fuel leaks, further protecting the environment from potential contamination 4.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to innovation and quality. With a history of producing reliable and high-performance components, Cummins offers a wide range of products designed to meet the demands of various applications. The company’s focus on technological advancement and customer satisfaction has established it as a trusted name in the industry 1.

Cummins Engine Part 3630050: Fuel Supply Line

The Cummins part 3630050, a Fuel Supply Line, is a component in the fuel delivery system of various Cummins engines. This part ensures the efficient and reliable transfer of fuel from the fuel tank to the engine, maintaining the necessary fuel pressure and flow for optimal engine performance 2.

K50 Engine Series

In the K50 engine series, the Fuel Supply Line part 3630050 is integral to the engine’s fuel management system. This line is designed to withstand the high pressures and temperatures associated with diesel fuel delivery, ensuring durability and longevity. The part is engineered to fit seamlessly with the engine’s fuel system architecture, providing a secure connection that prevents leaks and maintains fuel efficiency 3.

The K50 engines, known for their robust design and reliability, benefit significantly from the precision engineering of the part 3630050. This fuel supply line is compatible with the specific fuel system requirements of the K50 engines, ensuring that the engine operates smoothly and efficiently under various conditions 4.

Grouping of Cummins Engines

The Cummins part 3630050 is not limited to the K50 engine series alone. It is designed to be compatible with a range of Cummins engines, ensuring a standardized fit across multiple engine models. This compatibility is achieved through meticulous design and manufacturing processes that adhere to Cummins’ stringent quality standards 1.

By using the part 3630050 in various Cummins engines, technicians and mechanics can ensure that the fuel delivery system is functioning correctly, thereby maintaining the engine’s performance and reliability. The part’s design allows for easy installation and maintenance, making it a preferred choice for engine servicing and repairs 2.

Role of Part 3630050 Fuel Supply Line in Engine Systems

The 3630050 Fuel Supply Line is integral to the efficient operation of various engine systems. It ensures a consistent and reliable flow of fuel from the fuel tank to the engine’s fuel injection system. This part interfaces with several key components to maintain optimal engine performance 3.

Integration with Fuel Injection System

The Fuel Supply Line connects to the fuel injection system, providing the necessary fuel pressure and volume required for precise fuel delivery. This ensures that the injectors receive a steady supply of fuel, which is vital for maintaining engine performance and efficiency 4.

Connection to Oil Transfer System

In engines where the oil transfer connection is utilized, the Fuel Supply Line may indirectly influence the oil transfer process. Efficient fuel delivery ensures that the engine operates smoothly, reducing the likelihood of issues that could affect oil transfer components. Proper fuel supply helps maintain engine health, which in turn supports the oil transfer system’s function 1.

Role in Performance Parts

When upgrading to performance parts, the Fuel Supply Line becomes even more significant. High-performance engines demand increased fuel flow to meet their elevated power requirements. The 3630050 Fuel Supply Line must be capable of handling higher fuel volumes and pressures without restriction, ensuring that performance parts operate at their peak 2.

Ensuring Component Reliability

The reliability of the Fuel Supply Line directly impacts the durability and efficiency of connected components. A well-maintained Fuel Supply Line prevents fuel starvation, which can lead to engine misfires or damage to fuel injectors and other sensitive parts 3.

Conclusion

In summary, the 3630050 Fuel Supply Line is a foundational component that supports the seamless operation of the fuel injection system, enhances the performance of upgraded parts, and contributes to the overall reliability of the engine system. Its role in ensuring efficient fuel delivery, compatibility with various engine models, and contribution to environmental sustainability make it a critical component in the maintenance and operation of heavy-duty trucks 4.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ ↩ ↩ ↩ ↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.