3628518

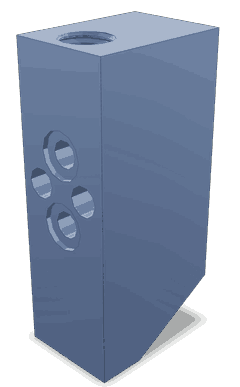

Fuel Block Connection

Cummins®

IN STOCK

7 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3628518 Fuel Block Connection, manufactured by Cummins, is a critical component in the fuel system of heavy-duty trucks. Cummins, a prominent figure in the commercial truck industry, is known for its dedication to quality and innovation in engine components. This part facilitates the distribution of fuel to the injectors, ensuring efficient and reliable engine operation 3.

Basic Concepts of Fuel Block Connection

A fuel block connection interfaces with the fuel rail and injectors within a diesel engine’s fuel system. Its primary role is to maintain consistent fuel pressure and ensure efficient fuel delivery to each injector. This connection is essential for the synchronization of fuel delivery, directly impacting the engine’s performance and efficiency 1.

Purpose of the 3628518 Fuel Block Connection

The 3628518 Fuel Block Connection is designed to ensure that fuel is delivered under the correct pressure to the injectors, which is vital for the combustion process. By maintaining optimal fuel pressure, this component contributes to the engine’s overall efficiency and performance, ensuring that the truck operates smoothly under various conditions 3.

Key Features

This Cummins part is constructed from high-quality materials that enhance its durability and performance. Its design includes features that ensure a secure fit and reliable operation, even under the demanding conditions typical of heavy-duty truck use. Advanced sealing technologies and precision engineering are unique attributes of this component, setting it apart in terms of reliability and efficiency 2.

Benefits

Utilizing the 3628518 Fuel Block Connection offers several advantages, including improved fuel efficiency and enhanced engine performance. Consistent fuel pressure contributes to more efficient combustion. Additionally, the reliability of this component under various operating conditions ensures that heavy-duty trucks can maintain their performance and efficiency over time 3.

Installation Process

Installing the 3628518 Fuel Block Connection involves several steps to ensure proper fit and function. Preparatory steps include ensuring the fuel system is clean and free of debris. The installation requires specific tools, and following the manufacturer’s guidelines is recommended to achieve a secure and efficient connection. Best practices during installation include checking for proper alignment and ensuring all connections are tight to prevent leaks 3.

Troubleshooting Common Issues

Common issues with the 3628518 Fuel Block Connection may include leaks or malfunctions. Troubleshooting these problems involves inspecting the connection for signs of wear or damage, checking the fuel pressure to ensure it meets specifications, and verifying that all connections are secure. Addressing these issues promptly can help maintain the efficiency and reliability of the fuel system 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 3628518 Fuel Block Connection, regular maintenance is recommended. This includes inspecting the component for signs of wear or damage at regular intervals, cleaning the connection points to prevent buildup, and following the manufacturer’s guidelines for when to consider replacement. Proper maintenance can significantly extend the life of the component and ensure consistent engine performance 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of engine components and systems, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to quality and innovation is evident in its engine components, including the 3628518 Fuel Block Connection 3.

Compatibility with Cummins Engines

The Cummins Fuel Block Connection part number 3628518 is designed to integrate seamlessly with a variety of Cummins engines, including the K38 and K50 series. This part is crucial for ensuring the proper flow of fuel within the engine system, maintaining optimal performance and efficiency.

K38 Series

In the K38 engine series, the Fuel Block Connection part 3628518 is engineered to fit precisely with the engine’s fuel system architecture. This ensures that the fuel is delivered consistently and efficiently, which is vital for the engine’s overall operation. The design of this part allows for easy installation and removal, facilitating maintenance and repairs.

K50 Series

Similarly, for the K50 engine series, the Cummins Fuel Block Connection part 3628518 is tailored to match the specific requirements of the engine’s fuel system. This part plays a pivotal role in the fuel delivery mechanism, ensuring that the engine receives the correct amount of fuel at the right pressure. The compatibility of this part with the K50 series underscores its versatility and importance in maintaining engine performance.

Grouping for Efficiency

When considering the K38 and K50 engines together, it is evident that the Fuel Block Connection part 3628518 is designed with a focus on efficiency and reliability. Both engine series benefit from this part’s precise fit and robust construction, which helps to prevent fuel leaks and other issues that could compromise engine performance. The commonality in design allows for streamlined maintenance and repair processes, making it easier for technicians to work on these engines.

Understanding the Role of 3628518 Fuel Block Connection in Engine Systems

The 3628518 Fuel Block Connection is an integral component in the orchestration of fuel delivery within engine systems. Its primary function is to ensure a secure and efficient connection between various fuel system components, facilitating the seamless flow of fuel from the fuel manifold to the injectors.

Integration with Fuel System Components

Fuel Manifold and Injectors

The Fuel Block Connection interfaces directly with the fuel manifold, which acts as a distribution hub for fuel. This connection ensures that fuel is evenly distributed to each injector. The injectors, in turn, atomize the fuel into the combustion chamber, where it mixes with air and ignites to produce power.

Fuel Balance Connection

In systems equipped with a fuel balance connection, the Fuel Block Connection plays a role in maintaining equilibrium across the fuel delivery system. This balance is essential for optimal engine performance and efficiency, ensuring that each cylinder receives the correct amount of fuel.

Diagnostic Retrofit and Performance Kit

When incorporated into a diagnostic retrofit or performance kit, the Fuel Block Connection can enhance the engine’s diagnostic capabilities and performance. It allows for more precise fuel delivery, which is critical for engines that require fine-tuned fuel management to achieve peak performance.

Base Parts and Plumbing

The connection is also a key component in the base parts of the fuel system, where it interfaces with the fuel supply plumbing. This integration ensures that the fuel supply line is securely connected to the fuel manifold, preventing leaks and ensuring a consistent fuel supply.

Injector Plumbing

In the context of injector plumbing, the Fuel Block Connection ensures that each injector is properly connected to the fuel manifold. This is vital for the uniform delivery of fuel to each cylinder, which is essential for balanced engine operation and performance.

Conclusion

In summary, the 3628518 Fuel Block Connection is a pivotal element in the fuel delivery system, ensuring that fuel is efficiently and effectively distributed from the manifold to the injectors. Its role in connecting and securing various components within the fuel system underscores its importance in maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.