Introduction

The Cummins 3628247 Fuel Supply Tube is a critical component in the fuel systems of heavy-duty trucks. It ensures a consistent and reliable fuel supply from the tank to the engine, which is essential for optimal engine performance.

Purpose and Function

This Cummins part facilitates the transport of fuel within the delivery system, providing a conduit from the storage tank to the engine. It ensures the engine receives the precise amount of fuel required for combustion under varying load conditions 1.

Design and Construction

Constructed from durable materials, the Fuel Supply Tube is designed to withstand the pressures and temperatures within a heavy-duty truck’s fuel system. It may feature protective coatings or reinforcements to enhance durability and resistance to wear and corrosion. The design includes fittings and connections that ensure a secure and leak-free attachment to other components within the fuel system 2.

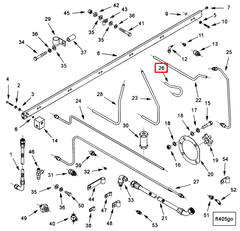

Installation Process

Proper installation of the 3628247 involves several steps to ensure it is correctly positioned and securely attached. This process typically requires specific tools and equipment to handle the connections and ensure they are tightened to the manufacturer’s specifications. Careful attention to detail during installation helps prevent leaks and ensures the tube functions as intended within the fuel system.

Common Issues and Troubleshooting

Typical problems associated with this part include leaks and blockages. These issues can arise from wear and tear, improper installation, or damage to the tube. Troubleshooting methods may involve inspecting the tube and connections for signs of wear, ensuring all fittings are secure, and checking for any obstructions within the tube that could impede fuel flow.

Maintenance Tips

Regular maintenance practices for the Fuel Supply Tube include periodic inspections for signs of wear or damage, ensuring all connections are tight, and verifying that the tube is free from obstructions. Keeping the fuel system clean and free from contaminants also contributes to the longevity and efficiency of the fuel supply tube 3.

Safety Considerations

When working with the 3628247, it is important to follow safety guidelines and precautions. This includes ensuring the fuel system is depressurized before beginning any work, using appropriate personal protective equipment, and being aware of the hazards associated with fuel handling and system pressure. Adhering to these safety practices helps protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the manufacturing of diesel engines and components, including fuel system parts like the 3628247. The company’s commitment to innovation and quality has made it a preferred choice for heavy-duty truck applications.

Role of Part 3628247 Fuel Supply Tube in Engine Systems

This part is an integral component in the fuel delivery system of various engine setups. It is responsible for transporting fuel from the fuel tank to the fuel injectors or carburetor, ensuring a consistent and reliable fuel supply to the engine.

Integration with Fuel System Components

- Fuel Tank: The Fuel Supply Tube connects directly to the fuel tank, where it draws fuel through a fuel pump or by gravity, depending on the system design.

- Fuel Pump: In systems equipped with an electric or mechanical fuel pump, the Fuel Supply Tube is positioned downstream of the pump. It receives pressurized fuel and directs it toward the engine.

- Fuel Filter: Often, the Fuel Supply Tube is routed through a fuel filter. This filter removes impurities and contaminants from the fuel, protecting sensitive engine components from damage.

- Fuel Rail (for Fuel-Injected Engines): In fuel-injected engines, the Fuel Supply Tube feeds into the fuel rail. The fuel rail distributes fuel to each injector, which then sprays it into the combustion chamber.

- Carburetor (for Carbureted Engines): In engines with a carburetor, the Fuel Supply Tube delivers fuel directly to the carburetor. The carburetor mixes the fuel with air before it enters the engine cylinders.

- Fuel Pressure Regulator: Some systems incorporate a fuel pressure regulator, which may be connected to the Fuel Supply Tube. This regulator maintains consistent fuel pressure within the system.

- Return Line: In systems with a return line, excess fuel is sent back to the tank via a separate tube. The Fuel Supply Tube ensures that only the necessary amount of fuel is delivered to the engine, with the remainder returned to maintain system pressure.

Operational Dynamics

The Fuel Supply Tube operates under various pressures depending on the engine’s demand and the system’s design. It must be robust enough to withstand these pressures while remaining flexible to accommodate engine movement and vibration.

Maintenance and Inspection

Regular inspection of the Fuel Supply Tube is essential to ensure there are no leaks, cracks, or signs of wear. Any damage to the tube can lead to fuel leaks, which pose a fire hazard, or insufficient fuel delivery, which can cause engine performance issues.

Conclusion

The 3628247 plays a significant role in the efficient and safe operation of an engine’s fuel system. Its proper function is essential for the delivery of fuel to the engine components that require it, ensuring optimal performance and reliability.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.