Introduction

The Cummins 3626592 Fuel Supply Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the transfer of fuel from the tank to the engine, ensuring a consistent and reliable fuel supply that is vital for the operation of the vehicle. This tube is engineered to meet the demanding requirements of heavy-duty applications, providing a durable and efficient solution for fuel delivery 1.

Purpose and Function

The Cummins 3626592 Fuel Supply Tube plays a role in the fuel system by connecting the fuel tank to the engine’s fuel injection system. It allows for the smooth and uninterrupted flow of fuel, which is necessary for the engine to operate efficiently. The tube is designed to withstand the pressures and temperatures associated with diesel fuel systems, ensuring that fuel is delivered consistently under various operating conditions 2.

Key Features

The design and construction of the Cummins 3626592 Fuel Supply Tube incorporate several features that enhance its performance. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring durability in harsh operating environments. The tube’s construction includes precise fittings and connections that provide a secure and leak-free seal, contributing to the overall reliability of the fuel system 3.

Benefits

Using the Cummins 3626592 Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring a consistent fuel flow, which can lead to better overall performance of the truck. The tube’s robust construction and reliable design also enhance the longevity of the fuel system, reducing the need for frequent replacements or repairs. Additionally, its compatibility with Cummins engines ensures optimal performance and efficiency 4.

Installation Process

Installing the Cummins 3626592 Fuel Supply Tube requires careful attention to detail to ensure a proper fit and function. The process involves disconnecting the old tube, cleaning the fuel system components, and attaching the new tube using the appropriate tools and equipment. It is important to follow the manufacturer’s guidelines for installation to ensure that the tube is securely fitted and that all connections are tight and leak-free.

Common Issues and Troubleshooting

Typical problems that may arise with the Fuel Supply Tube include leaks or blockages. These issues can often be diagnosed through visual inspection and pressure testing. Troubleshooting methods may involve checking for proper connections, inspecting for damage or wear, and ensuring that the tube is free from obstructions. Addressing these issues promptly can help maintain the efficiency and reliability of the fuel system.

Maintenance Tips

Regular maintenance of the Cummins 3626592 Fuel Supply Tube is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the tube and connections to prevent buildup, and checking for proper installation and fit. Adhering to recommended maintenance schedules can help identify potential issues before they become significant problems.

Safety Considerations

When working with the Fuel Supply Tube, it is important to observe safety protocols and precautions. This includes handling fuel with care to avoid spills and ensuring that the system is depressurized before making any adjustments or repairs. Additionally, working with high-pressure systems requires attention to personal protective equipment and following manufacturer guidelines to prevent accidents or injuries.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of engines, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing reliable and high-performance engine components, including the 3626592 Fuel Supply Tube.

Application in Cummins Engines

The Cummins Fuel Supply Tube part number 3626592 is designed to fit seamlessly within the Cummins K19 engine series. This series is known for its robust design and reliability, often used in heavy-duty applications such as construction equipment, agricultural machinery, and industrial power systems.

In the K19 engine, the fuel supply tube is integral to the overall fuel management system. It connects the fuel tank to the fuel injection system, ensuring that the engine receives the necessary fuel for combustion. The design of this tube is critical to prevent leaks and maintain pressure integrity, which is essential for the engine’s performance.

Compatibility and Installation

When installing the Cummins Fuel Supply Tube part number 3626592, it is essential to follow the manufacturer’s guidelines to ensure proper fitment and function. This part is typically compatible with other components in the K19 engine series, making it a straightforward replacement or upgrade option.

The installation process involves securing the tube to the fuel tank and the fuel injection system, ensuring all connections are tight and leak-free. Proper installation is crucial for maintaining the engine’s efficiency and preventing potential fuel-related issues.

Importance of the Fuel Supply Tube

The fuel supply tube plays a vital role in the engine’s operation by:

- Ensuring a consistent fuel supply to the engine.

- Maintaining fuel pressure within the system.

- Preventing fuel leaks, which can lead to safety hazards and engine performance issues.

By using the Cummins part number 3626592, engine operators can be confident in the reliability and performance of their fuel delivery system, contributing to the overall longevity and efficiency of the K19 engine series.

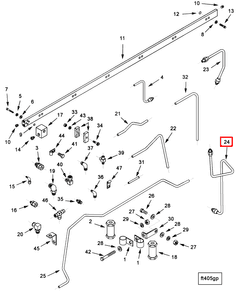

Integration with Fuel System Components

-

Fuel Tank: The fuel supply tube connects directly to the fuel tank, where it draws fuel through a pickup tube or directly from the tank’s outlet. This connection ensures that the fuel is efficiently siphoned and prepared for delivery to the engine.

-

Fuel Pump: In systems equipped with an electric fuel pump, the fuel supply tube is linked to the pump’s outlet. The pump pressurizes the fuel, which is then channeled through the tube towards the engine. This pressurized flow is vital for maintaining the correct fuel pressure required by the injectors.

-

Fuel Filter: Often, the fuel supply tube is routed through a fuel filter before reaching the engine. The filter removes impurities and contaminants from the fuel, ensuring that only clean fuel reaches the injectors or carburetor, which helps in maintaining engine performance and longevity.

-

Fuel Rail: In fuel-injected engines, the fuel supply tube delivers fuel to the fuel rail. The rail distributes the fuel to individual injectors, which then spray the fuel into the combustion chambers at precise moments for optimal combustion.

-

Carburetor: In carbureted engines, the fuel supply tube feeds fuel directly into the carburetor. The carburetor then mixes the fuel with air before the mixture is drawn into the engine’s cylinders.

-

Return Line: Some fuel systems include a return line that sends excess fuel back to the tank. The fuel supply tube may connect to this return line, ensuring that only the necessary amount of fuel is delivered to the engine while the rest is efficiently recycled.

Ensuring Reliable Fuel Delivery

The part 3626592 Fuel Supply Tube is designed to withstand the pressures and temperatures within the fuel system, providing a durable and reliable pathway for fuel. Its proper installation and maintenance are key to ensuring that the engine receives a consistent fuel supply, which is fundamental for engine performance and efficiency.

Conclusion

The Cummins 3626592 Fuel Supply Tube is a critical component in the fuel delivery system of Cummins engines, particularly within the K19 series. Its design ensures a consistent and reliable fuel supply, contributing to the engine’s performance and efficiency. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.