This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3625327 Fuel Drain Tube is a component designed for use in the fuel systems of commercial trucks. Its primary role is to facilitate the draining of fuel from the system, which is important for maintenance and ensuring the integrity of the fuel system. This part is part of Cummins Inc.’s lineup of fuel system components, which are engineered to enhance the performance and reliability of commercial vehicles.

Purpose and Function

The Cummins 3625327 serves a specific function within the fuel system of a truck. It allows for the controlled release of fuel, which is necessary during maintenance procedures such as filter changes or when purging air from the system. By enabling the draining of fuel, this component helps maintain the cleanliness and efficiency of the fuel system, ensuring that the engine receives a consistent supply of clean fuel 1.

Key Features

This Cummins part is constructed with durability and functionality in mind. It is made from materials that are resistant to the corrosive effects of diesel fuel, ensuring a long service life. The tube features secure connection points that are designed to prevent leaks and maintain a tight seal within the fuel system. Additionally, the design of the tube may include features that simplify the draining process, such as a straightforward valve mechanism or an ergonomic handle for easy operation 2.

Benefits

Utilizing the Cummins 3625327 offers several advantages. It contributes to improved fuel system performance by allowing for efficient maintenance routines. The reliability of the tube ensures that the fuel system operates without unexpected interruptions. Furthermore, the ease of maintenance afforded by this component can lead to reduced downtime for commercial trucks, which is beneficial for fleet operations 3.

Installation Process

Installing the Cummins 3625327 requires careful attention to detail to ensure proper function and safety. The process involves locating the designated point within the fuel system where the tube will be installed. It is important to use the correct tools to make any necessary connections secure. Precautions should be taken to ensure that the fuel system is depressurized before beginning the installation to avoid fuel spills or accidents 4.

Maintenance and Troubleshooting

To maintain the Cummins 3625327, regular inspections should be conducted to check for signs of wear or damage. Common issues may include leaks at connection points or blockages within the tube. Basic troubleshooting can involve checking the seals and connections, and ensuring that the valve operates smoothly. If problems are detected, it may be necessary to clean or replace the tube to maintain optimal performance.

Safety Considerations

When working with the Cummins 3625327, it is important to observe safety practices to protect against the hazards associated with fuel handling. This includes wearing appropriate personal protective equipment, ensuring proper ventilation when draining fuel, and verifying that all connections are secure to prevent leaks. It is also crucial to follow the manufacturer’s guidelines for handling and disposing of fuel to maintain a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and fuel systems. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to innovation and quality, providing components and systems that are designed to meet the demanding requirements of commercial vehicle operators.

Compatibility

This Cummins part is designed to fit seamlessly with a variety of Cummins engines. It is crucial for maintaining the integrity of the fuel system by allowing for the removal of water and sediment that can accumulate in the fuel tank.

V903 Engines

The V903 engine series benefits significantly from the use of the 3625327. This part is engineered to integrate with the V903 engine’s fuel system, ensuring efficient drainage and preventing potential contamination that could lead to engine performance issues. The design of the tube allows for easy installation and reliable operation, making it a vital component for the longevity and efficiency of the V903 engine.

Grouping of Compatible Engines

While the V903 is a notable series, the 3625327 is also compatible with other Cummins engines that share similar fuel system configurations. This includes engines within the same family or those that have been designed with similar fuel management systems. The compatibility extends to various models, ensuring that the part can be used across multiple engine types without modification.

The integration of the 3625327 into the engine’s fuel system is straightforward, thanks to its precise engineering. This ensures that the part fits snugly and functions optimally, contributing to the overall health and performance of the engine.

Role of Part 3625327 in Engine Systems

The Fuel Drain Tube, identified by part number 3625327, is an integral component in the fuel system of various engine setups. It works in conjunction with several other components to ensure the efficient and safe operation of the fuel system.

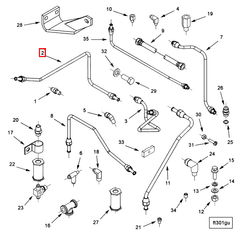

Integration with Fuel Delivery System

In the fuel delivery system, the Fuel Drain Tube is typically connected to the fuel supply lines. Its primary function is to provide a controlled path for fuel to be drained from the system. This is particularly important during maintenance procedures or when the fuel needs to be changed. The tube is often mounted using Fuel Drain Tubing Mounting brackets, which secure it in place and ensure it remains aligned with the fuel supply lines.

Interaction with Plumbing Components

The Fuel Drain Tube is a key element in the overall plumbing of the fuel system. It interfaces with various plumbing components to facilitate the drainage process. This includes connections to fuel filters, fuel tanks, and other ancillary components within the fuel system. Proper alignment and secure fitting of the tube with these components are essential for maintaining the integrity of the fuel system and preventing leaks.

Coordination with Fuel Supply Lines

The Fuel Drain Tube operates in tandem with the fuel supply lines to manage the flow of fuel within the engine system. When draining is required, the tube allows fuel to be safely removed from the system without disrupting the normal operation of the fuel supply. This coordination is vital for maintaining consistent fuel pressure and flow, which are critical for engine performance.

Maintenance and Safety Considerations

During maintenance, the Fuel Drain Tube plays a significant role in ensuring that the fuel system can be safely and effectively drained. This is particularly important in high-pressure fuel systems where the release of fuel must be controlled to avoid spills or unsafe conditions. The tube’s design and placement are engineered to facilitate easy access for draining while minimizing the risk of fuel exposure to the environment.

Conclusion

In summary, the Fuel Drain Tube (part 3625327) is a vital component that interacts with the fuel supply lines, plumbing components, and mounting systems to ensure the safe and efficient drainage of fuel from the engine system. Its proper installation and maintenance are essential for the overall functionality and safety of the fuel system.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

Gunnar Stiesch, Modeling Engine Spray and Combustion Processes, Springer Verlag, 2003.

↩ -

Tim Gilles, Automotive Service: Inspection, Maintenance, Repair: 2nd Edition, Cengage Learning, 2020.

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels, Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.