Introduction

The Cummins 3607142 Fuel Cleaner is engineered to optimize the fuel system’s performance in commercial trucks. It ensures that the fuel supplied to the engine is free from contaminants, which is essential for maintaining engine efficiency and longevity.

Purpose and Function

This Cummins part operates within the fuel system to filter out impurities and water. This contributes to the engine’s overall efficiency and performance by ensuring optimal combustion and reducing wear on engine components 1.

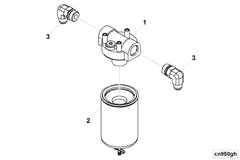

Key Features

The Fuel Cleaner is characterized by its robust design and high-quality materials. It features a high-capacity filter element capable of trapping a wide range of contaminants. Its design also facilitates easy maintenance and replacement, which is beneficial for commercial truck operations 2.

Benefits of Using a Fuel Cleaner

Incorporating the 3607142 into a truck’s fuel system offers several advantages, including improved fuel efficiency, reduced emissions, and prolonged engine life due to decreased contamination-related wear 3.

Installation Process

Installation of the 3607142 involves disconnecting the fuel lines, removing the old filter, and attaching the new Fuel Cleaner. It is crucial to use the correct tools and ensure all connections are secure to prevent fuel leaks 4.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Cleaner is vital for optimal performance. This includes periodic checks for contamination and timely replacement of the filter element. Common issues such as reduced fuel flow or engine performance can often be traced back to a clogged filter.

Impact on Engine Performance

The use of the 3607142 can significantly impact engine performance. It ensures that the fuel delivered to the engine is of high quality, leading to more efficient fuel combustion and contributing to the overall health of the engine.

Manufacturer - Cummins

Cummins Inc. is renowned in the commercial truck industry for its high-quality engine and component manufacturing. The company’s commitment to innovation and reliability is evident in products like the 3607142, designed to enhance the performance and efficiency of commercial vehicles.

Compatibility with Various Engine Models

The 3607142 is compatible with a range of Cummins engine models, including the B5.9, B6.7, C, C8.3, ISB, ISL, and L series. It ensures that these engines receive clean fuel, which is crucial for maintaining power output and longevity.

Role in Engine Systems

The 3607142 plays a crucial role in maintaining the efficiency and performance of various engine systems. It ensures that the fuel delivered to the engine is free from contaminants, which is essential for optimal engine operation.

Integration with Fuel Injectors

When integrated with fuel injectors, the Fuel Cleaner ensures that the fuel sprayed into the combustion chamber is clean. This prevents clogging of the injector nozzles, leading to uneven fuel distribution and inefficient combustion.

Contribution to Fuel Pumps

In conjunction with fuel pumps, the Fuel Cleaner helps maintain the pump’s longevity and efficiency by filtering out impurities that can cause wear and tear on pump components.

Impact on Fuel Lines

Fuel lines benefit from the Fuel Cleaner by remaining free from deposits and blockages. This ensures optimal fuel delivery to the engine.

Enhancement of Combustion Efficiency

The cleaner fuel provided by the Fuel Cleaner leads to more efficient combustion within the engine cylinders, which is particularly important for direct injection systems.

Support for Emission Control Systems

The Fuel Cleaner supports emission control systems by ensuring that the fuel entering the engine is free from contaminants that could interfere with the operation of catalytic converters and other emission control devices.

Preservation of Engine Components

Finally, the Fuel Cleaner aids in the preservation of various engine components, including the combustion chamber, pistons, and valves, by removing contaminants from the fuel.

Conclusion

The Cummins 3607142 Fuel Cleaner is a vital component in the maintenance of engine systems. It ensures that the fuel delivered to the engine is clean and free from impurities, which is essential for optimal engine performance and longevity.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.