This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

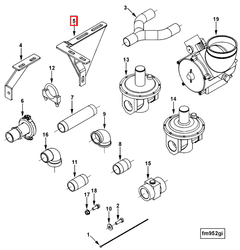

The Fuel Control Valve Bracket, identified by part number 3394947, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket plays a significant role in the operational efficiency of trucks by securely holding the fuel control valve in place. Its design and functionality are integral to the proper functioning of the truck’s fuel system, ensuring that the fuel control valve operates within the specified parameters for optimal engine performance 1.

Purpose and Function

The Fuel Control Valve Bracket serves as a mounting point for the fuel control valve, which regulates the flow of fuel to the engine. By providing a stable and secure attachment point, the bracket ensures that the fuel control valve can operate effectively. This interaction is vital for maintaining the correct fuel pressure and flow rate, which are essential for engine efficiency and performance 2.

Key Features

This Cummins part is designed with several features that enhance its performance and durability. Constructed from high-strength materials, it is built to withstand the rigors of truck operations. The bracket includes precise mounting points that ensure a secure fit for the fuel control valve, minimizing the risk of vibration-induced loosening. Its design also incorporates features that facilitate easy installation and maintenance, contributing to the overall efficiency of truck operations 3.

Benefits

The use of the Fuel Control Valve Bracket offers several advantages. It contributes to improved fuel system efficiency by ensuring the fuel control valve is securely mounted and operates within its designed parameters. The bracket’s durable construction enhances the longevity of the fuel control valve and the fuel system as a whole. Additionally, by maintaining optimal fuel flow and pressure, the bracket plays a role in enhancing the overall performance and efficiency of the truck’s engine 4.

Installation and Compatibility

Proper installation of the Fuel Control Valve Bracket is crucial for its effective function within the truck’s fuel system. Installation guidelines recommend ensuring the bracket is correctly aligned with the mounting points on the truck’s fuel system before securing it in place. This step is important for maintaining the integrity of the fuel control valve’s operation. Compatibility with specific truck models and fuel systems should be verified to ensure optimal performance and integration 5.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Control Valve Bracket is recommended to ensure its continued effective operation. Inspection routines should include checking for signs of wear or damage, ensuring all mounting points are secure, and verifying that the fuel control valve is functioning correctly. Cleaning procedures may involve removing any accumulated dirt or debris that could affect the bracket’s performance. Troubleshooting tips for common issues, such as leaks or improper fuel flow, may include re-securing the bracket or inspecting the fuel control valve for malfunctions.

Common Issues and Solutions

Frequent problems associated with the Fuel Control Valve Bracket may include loosening of the mounting points, leading to instability of the fuel control valve, or damage to the bracket itself. Solutions to these issues involve re-securing the bracket, replacing damaged components, or adjusting the fuel control valve as necessary. Preventive measures include regular inspections and maintenance to identify and address potential issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Cummins Fuel Control Valve Bracket 3394947 Compatibility

The Cummins Fuel Control Valve Bracket, part number 3394947, is designed to integrate seamlessly with a variety of Cummins engine models. This bracket plays a crucial role in the engine’s fuel management system, ensuring that the fuel control valve is securely mounted and properly aligned.

G8.3 Engine Series

The G8.3 engine series, known for its robust performance and reliability, is one of the key beneficiaries of this bracket. The 3394947 bracket is engineered to fit perfectly with the G8.3 engines, providing a stable mounting point for the fuel control valve. This ensures optimal fuel delivery and engine performance, which is critical for the demanding applications these engines are typically used in.

Other Cummins Engines

While the G8.3 series is a notable application, the 3394947 bracket is also compatible with other Cummins engine models. Its design allows it to be used across various engine configurations, ensuring that the fuel control valve is securely fastened and properly positioned. This compatibility extends to other high-performance and heavy-duty Cummins engines, making it a versatile component in the Cummins engine ecosystem.

The bracket’s precision engineering ensures that it fits snugly and securely, reducing the risk of misalignment and potential engine issues. This makes it a reliable choice for maintaining the integrity of the fuel control system across different engine types.

Conclusion

The Fuel Control Valve Bracket, part number 3394947, is an integral component in the assembly and operation of various engine systems. It serves as a mounting point for the fuel control valve, ensuring it is securely positioned within the engine module. This bracket facilitates the precise alignment and stability of the valve, which is essential for the valve’s function in regulating fuel flow.

In conjunction with the pressure regulator, the Fuel Control Valve Bracket helps maintain consistent fuel pressure within the system. The bracket’s design allows for efficient heat dissipation from the valve, contributing to the overall reliability and performance of the fuel control system.

The integration of the Fuel Control Valve Bracket with the fuel control module enhances the module’s capability to monitor and adjust fuel delivery in response to engine demands. This synergy between components ensures optimal engine performance and fuel efficiency.

The bracket’s role extends to supporting the valve during engine vibrations and operational stresses, preserving the integrity of the fuel control system. Its presence is a testament to the engineering precision required in modern engine systems, where each component must work in harmony to achieve peak performance.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual for Z13 CM2880 Z104G, Bulletin Number 5659689.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.