This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3394926 Fuel Transfer Tube is a component designed for heavy-duty trucks, ensuring efficient and reliable fuel transfer from the tank to the engine. This part is crucial for maintaining the performance and efficiency of the vehicle’s fuel delivery system.

Purpose and Function

This Cummins part facilitates the movement of fuel from the storage tank to the engine, ensuring a consistent fuel supply vital for engine operation. It is designed to handle the pressures and temperatures associated with fuel transfer in heavy-duty applications, contributing to the overall efficiency and reliability of the fuel system 1.

Key Features

The Fuel Transfer Tube is constructed from durable materials resistant to fuel corrosion and high temperatures. Its design includes reinforced connections and a smooth interior to minimize fuel flow resistance. The build quality ensures it can withstand heavy-duty use, providing a reliable fuel transfer solution 2.

Benefits

Using the 3394926 offers several advantages. It contributes to improved fuel efficiency by ensuring a smooth and consistent fuel flow to the engine. The tube’s reliable design enhances the overall reliability of the fuel system, reducing the likelihood of fuel-related issues. Additionally, its construction facilitates ease of maintenance, allowing for straightforward inspection and replacement when necessary 3.

Installation Process

Installing the Fuel Transfer Tube requires careful attention to ensure proper fitting and function. The process involves disconnecting the old tube, cleaning the fuel system components, and securely attaching the new tube. Tools such as wrenches and fuel system cleaners may be required. It is important to follow manufacturer guidelines to ensure the tube is correctly installed and sealed to prevent fuel leaks 4.

Common Issues and Troubleshooting

Typical problems with the Fuel Transfer Tube may include leaks, blockages, or damage from wear and tear. Troubleshooting steps involve inspecting the tube for visible damage, checking connections for tightness, and ensuring there are no obstructions in the fuel path. Solutions may range from tightening connections to replacing the tube if it is damaged 1.

Maintenance Tips

Regular maintenance of the 3394926 is key to prolonging its life and ensuring optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the tube and its connections to remove any buildup, and following manufacturer recommendations for replacement intervals. Adhering to these practices helps maintain the efficiency and reliability of the fuel system 2.

Safety Considerations

When working with the Fuel Transfer Tube, it is important to observe safety precautions to prevent accidents. This includes working in a well-ventilated area, avoiding smoking or open flames near the fuel system, and wearing appropriate personal protective equipment. Following these guidelines ensures safe operation and maintenance of the fuel transfer system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive industry, particularly in the heavy-duty truck segment, Cummins is known for its high-quality components and innovative technologies that enhance vehicle performance and efficiency 4.

Compatibility

The Cummins Fuel Transfer Tube, part number 3394926, is compatible with certain engine models, including the G8.3 engine series. This part is designed to fit seamlessly within the fuel system architecture of these engines, facilitating the smooth transfer of fuel and maintaining optimal engine performance. Users should consult their engine’s specific service manual or a Cummins authorized dealer to confirm compatibility with other engine types 1.

Role in Engine Systems

The 3394926 Fuel Transfer Tube is integral to the efficient operation of various engine systems. It facilitates the seamless movement of fuel between different parts of the engine, ensuring optimal performance and reliability.

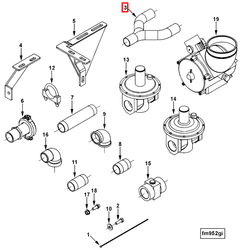

Integration with the Fuel Control Module

The Fuel Transfer Tube works in conjunction with the Fuel Control Module to regulate the fuel supply. The module monitors and adjusts the fuel flow based on engine demand and operating conditions. The tube ensures a consistent and uninterrupted fuel supply, allowing the module to maintain precise control over fuel delivery 2.

Interaction with the Fuel Valve

The Fuel Transfer Tube is connected to the Fuel Valve, which controls the opening and closing of the fuel passage. The tube’s role is to transport fuel from the storage area to the valve. This ensures that the valve receives a steady fuel flow, enabling it to operate efficiently and respond quickly to changes in engine demand 3.

Coordination with the Pressure Regulator

In systems equipped with a Pressure Regulator, the Fuel Transfer Tube plays a key role in maintaining the desired fuel pressure. The tube delivers fuel to the regulator, which then adjusts the pressure to meet the engine’s requirements. This coordination ensures that the engine receives fuel at the correct pressure, enhancing combustion efficiency and overall performance 4.

Conclusion

The Cummins 3394926 Fuel Transfer Tube is a vital component in the fuel system of heavy-duty trucks, ensuring efficient and reliable fuel transfer. Its durable construction, ease of maintenance, and compatibility with various engine models make it an essential part for maintaining optimal engine performance and fuel efficiency.

-

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ ↩ ↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩ ↩ ↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011

↩ ↩ ↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.