This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

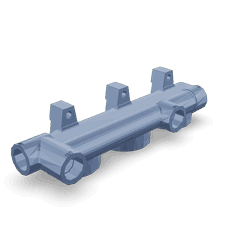

The Cummins 3332077 Tube Nut is a component used in commercial truck maintenance and operation. It is designed to facilitate secure connections within various truck systems, ensuring the integrity and efficiency of these systems. Understanding its purpose and functionality is important for maintaining the performance and reliability of commercial trucks.

Basic Concepts and Functionality

A tube nut is a type of fastener used to connect and secure components within a truck’s system. It typically consists of a threaded nut that fits over a tube or pipe, providing a tight seal and secure connection. The Cummins 3332077 Tube Nut functions similarly, playing a role in connecting and securing components within the truck’s system, ensuring that fluids and gases are properly contained and directed 1.

Purpose of the 3332077 Tube Nut

The Cummins 3332077 Tube Nut serves a specific role in the operation of a truck. It is used in various truck systems and components to ensure secure connections. This includes applications in fuel systems, hydraulic systems, and other critical areas where secure and reliable connections are necessary. By providing a tight seal, the tube nut helps maintain the efficiency and safety of these systems 2.

Key Features

The Cummins 3332077 Tube Nut is designed with several key features that enhance its performance and durability. Its design includes precise threading to ensure a secure fit over tubes and pipes. The material composition is chosen to withstand the rigors of commercial truck operation, providing resistance to corrosion and wear. Additionally, any unique characteristics, such as a special coating or enhanced threading, contribute to its overall effectiveness.

Benefits

Using the Cummins 3332077 Tube Nut offers several benefits for fleet operators. These include improved reliability due to its secure connections, ease of installation thanks to its design, and long-term cost savings from reduced maintenance and replacement needs. The tube nut’s durability and performance contribute to the overall efficiency and safety of the truck’s systems.

Installation Process

Proper installation of the Cummins 3332077 Tube Nut involves several steps to ensure a secure and effective connection. Begin by ensuring the tube or pipe is clean and free of debris. Align the tube nut with the threading on the tube, and carefully screw it into place. Use the appropriate tools to tighten the tube nut to the manufacturer’s specified torque, avoiding over-tightening which can damage the threads. Inspect the connection to ensure it is secure and there are no leaks.

Troubleshooting and Maintenance

Common issues with the Cummins 3332077 Tube Nut may include signs of wear, corrosion, or improper installation. Regular inspections can help identify these issues early. If wear or corrosion is detected, the tube nut should be replaced to maintain the integrity of the connection. Ensuring proper installation techniques and regular maintenance can help prevent these issues and ensure the longevity and optimal performance of the tube nut.

Safety Considerations

When installing and maintaining the Cummins 3332077 Tube Nut, several safety considerations should be kept in mind. Proper handling of the tube nut is important to avoid damage. Adhere to the manufacturer’s torque specifications to prevent over-tightening, which can lead to thread damage or leaks. Regular inspections are crucial to identify any issues early and ensure the continued safety and reliability of the truck’s systems.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a history of developing reliable and efficient components, Cummins has built a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its dedication to the industry.

Tube Nut 3332077 Compatibility with Cummins Engines

The Tube Nut part number 3332077, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure tubes and pipes within the engine’s structure, ensuring a tight and reliable connection. Here is a detailed look at its compatibility across various Cummins engines:

QSK45 CM500 and QSK60 CM500

The Tube Nut 3332077 is compatible with the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in heavy-duty applications. The Tube Nut ensures that the tubes and pipes remain securely fastened, which is crucial for maintaining the integrity of the engine’s cooling and exhaust systems.

QSK60 CM850 MCRS and QSK60G

The Tube Nut 3332077 also fits the QSK60 CM850 MCRS and QSK60G engines. These engines are designed for high-performance applications, often found in marine and industrial settings. The Tube Nut’s role in these engines is to provide a dependable connection for the tubes and pipes, which is essential for the efficient operation of the engine’s systems.

QSK78 CM500

Lastly, the Tube Nut 3332077 is compatible with the QSK78 CM500 engine. This engine is part of Cummins’ lineup of high-output, heavy-duty engines. The Tube Nut ensures that the tubes and pipes are securely fastened, contributing to the overall reliability and performance of the engine.

In summary, the Tube Nut 3332077 is a versatile and essential component that fits seamlessly into various Cummins engine models, ensuring the secure attachment of tubes and pipes.

Role of Part 3332077 Tube Nut in Engine Systems

The part 3332077 Tube Nut is an essential component in the assembly and functionality of various engine systems. Its primary role is to ensure secure and leak-free connections between different parts, contributing to the overall efficiency and reliability of the engine.

In the design phase of engine systems, the Tube Nut is strategically placed to connect critical components such as the fuel lines and filter assemblies. This ensures that the fuel system maintains consistent pressure and flow, which is vital for engine performance.

When considering alternative components or upgrades, the Tube Nut’s compatibility and secure fitting are key factors. It allows for easy replacement or modification of parts without compromising the integrity of the connections.

In the fuel system, the Tube Nut plays a significant role in connecting the fuel filter to the fuel lines. This connection is vital for maintaining the cleanliness of the fuel before it reaches the engine, ensuring optimal combustion and reducing wear on engine components.

The fuel filter head and fuel filter top-level assembly head also rely on the Tube Nut for secure attachment. These components work together to filter out impurities from the fuel, and the Tube Nut ensures that this process is uninterrupted and efficient.

In plumbing applications within the engine system, the Tube Nut is used to connect various hoses and pipes. Its design allows for easy installation and removal, facilitating maintenance and repairs.

Overall, the part 3332077 Tube Nut is a fundamental component in ensuring that the engine systems operate smoothly and efficiently. Its role in securing connections and preventing leaks is indispensable for the proper functioning of the engine.

Conclusion

The Cummins 3332077 Tube Nut is a critical component in the maintenance and operation of commercial trucks. Its role in ensuring secure and reliable connections within various truck systems is essential for maintaining the performance and reliability of these vehicles. Understanding its functionality, benefits, and proper installation techniques is crucial for fleet operators to ensure the longevity and optimal performance of their trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.