This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3282241 Fuel Injection Pump is a component designed for use in diesel engines, particularly in commercial trucks. It is integral to the efficient operation of these engines, ensuring that fuel is delivered to the engine cylinders at the correct timing and pressure. This part is part of Cummins’ lineup of fuel injection systems, which are known for their reliability and performance in demanding applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes fuel and delivers it to the engine’s combustion chambers. In diesel engines, this pump operates by using mechanical energy from the engine to create high-pressure fuel, which is then injected into the cylinders. The timing and pressure of this injection are critical for efficient combustion and engine performance. The pump works in conjunction with other components of the fuel delivery system to ensure that the engine receives the precise amount of fuel needed under varying conditions 1.

Purpose of the Cummins 3282241 Fuel Injection Pump

The Cummins 3282241 Fuel Injection Pump serves a specific role in the operation of a truck’s diesel engine. It is responsible for delivering fuel to the engine cylinders at precise timing and pressure. This ensures optimal combustion, which is vital for the engine’s efficiency, power output, and emissions control. The pump’s ability to maintain consistent fuel delivery under varying load conditions contributes to the overall performance and reliability of the engine.

Key Features

The Cummins 3282241 Fuel Injection Pump is characterized by several key features. Its design incorporates advanced technology to enhance performance and durability. This part is constructed using high-quality materials to withstand the rigors of commercial truck operation. It also features precise engineering to ensure accurate fuel delivery. Additionally, the pump may include unique technological advancements that improve its efficiency and reliability.

Benefits

The Cummins 3282241 Fuel Injection Pump offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in an optimal manner. This can lead to cost savings for truck operators. The pump also enhances engine performance, providing consistent power output and smooth operation. Furthermore, its reliable design helps to reduce downtime and maintenance costs, making it a valuable component for commercial truck fleets.

Installation Process

Installing the Cummins 3282241 Fuel Injection Pump requires careful attention to detail. The process involves several steps, including preparing the engine compartment, removing the old pump (if applicable), and installing the new pump. It is important to follow the manufacturer’s instructions and use the appropriate tools to ensure a proper installation. This may include torquing bolts to the specified settings and verifying that all connections are secure.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3282241 Fuel Injection Pump. This includes checking for leaks, ensuring that all connections are tight, and monitoring the pump’s performance. It is also important to use the recommended fuel and lubricants to prevent damage to the pump. Following the manufacturer’s maintenance schedule can help to identify and address potential issues before they become serious problems.

Troubleshooting Common Issues

Fuel injection pumps can encounter various issues over time. Common problems may include leaks, inconsistent fuel delivery, or pump failure. Troubleshooting these issues involves a systematic approach to diagnosing the problem. This may include checking for visible signs of damage, testing the pump’s performance, and consulting the manufacturer’s troubleshooting guide. Addressing these issues promptly can help to maintain the pump’s efficiency and reliability.

Performance Enhancements

For those looking to increase the power output or efficiency of their Cummins 3282241 Fuel Injection Pump, there are several potential enhancements. These may include upgrading to a higher-performance pump, modifying the fuel delivery system, or tuning the engine’s electronic control unit. It is important to consult with a professional to ensure that any modifications are compatible with the engine and do not void the warranty.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and quality, Cummins has established a strong reputation in the industry. The company is committed to advancing diesel engine technology, providing reliable and efficient solutions for commercial and industrial applications. Cummins’ dedication to research and development ensures that its products, including the 3282241 Fuel Injection Pump, meet the high standards expected by its customers.

Cummins Fuel Injection Pump 3282241 Compatibility

The Cummins Fuel Injection Pump part number 3282241 is a critical component in the operation of several engine models. This part is designed to ensure precise fuel delivery, which is essential for maintaining optimal engine performance and efficiency.

Cummins 6B5.9 Engine

The Cummins 6B5.9 engine is a robust and reliable power unit often utilized in various industrial and heavy-duty applications. The 3282241 fuel injection pump is specifically engineered to work seamlessly with the 6B5.9 engine, ensuring that it delivers the necessary fuel at the correct pressure and timing. This compatibility is crucial for maintaining the engine’s performance and longevity, as the pump’s precision in fuel delivery directly impacts the engine’s overall efficiency and power output.

Grouping of Compatible Engines

While the Cummins 6B5.9 engine is the primary focus here, it is important to note that the 3282241 fuel injection pump may also be compatible with other similar Cummins engines. This part is designed to meet the stringent requirements of Cummins engines, ensuring that it provides the same level of performance and reliability across different models.

For instance, the 3282241 pump may also be suitable for other engines within the same series or those that share similar design and operational parameters. This compatibility allows for easier maintenance and repair, as technicians can use a single part number for multiple engine models, reducing inventory complexity and ensuring quick availability of necessary components.

Role of Part 3282241 Fuel Injection Pump in Engine Systems

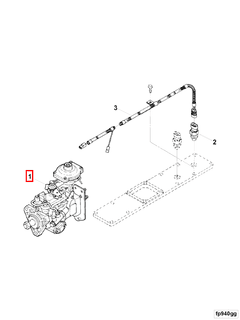

The Part 3282241 Fuel Injection Pump is an integral component within the Bosch Injection Pump system, orchestrating the precise delivery of fuel to the engine’s combustion chambers. This pump operates in concert with several key components to ensure optimal engine performance and efficiency.

Interaction with Key Components

-

Fuel Filter: Prior to entering the injection pump, fuel passes through the fuel filter. This step is essential for removing impurities and ensuring that only clean fuel is delivered to the pump. The pump’s performance is directly influenced by the quality of fuel it receives, making the fuel filter a vital preliminary component.

-

Fuel Lines: The fuel lines serve as the conduits that transport fuel from the tank to the injection pump and subsequently to the injectors. The integrity and condition of these lines are paramount, as they must withstand the pressure exerted by the pump while delivering fuel efficiently.

-

Injectors: Once pressurized by the injection pump, fuel is delivered to the injectors. These components atomize the fuel into a fine mist, facilitating a more complete and efficient combustion process. The timing and pressure of fuel delivery, controlled by the injection pump, are critical for the injectors’ performance.

-

Governor: The governor plays a regulatory role, adjusting the fuel delivery based on engine load and speed. It communicates with the injection pump to modulate fuel flow, ensuring that the engine operates within its designed parameters under varying conditions.

-

Timing Mechanism: Accurate timing is essential for the efficient operation of the injection pump. The timing mechanism ensures that fuel is delivered at the precise moment in the engine cycle, maximizing combustion efficiency and minimizing emissions.

-

Sensors and Control Units: Modern Bosch Injection Pump systems are equipped with sensors and control units that monitor various parameters such as engine speed, load, and temperature. These components provide feedback to the injection pump, allowing for dynamic adjustments to fuel delivery for optimal performance and emissions control.

In summary, the Part 3282241 Fuel Injection Pump is a central component within the Bosch Injection Pump system, working in harmony with fuel filters, fuel lines, injectors, governors, timing mechanisms, and sensors to deliver precise and efficient fuel to the engine. This collaboration ensures that the engine operates smoothly, efficiently, and within its designed performance parameters.

Conclusion

The Cummins 3282241 Fuel Injection Pump is a critical component in the operation of diesel engines, particularly in commercial trucks. Its role in ensuring precise fuel delivery at the correct timing and pressure is essential for maintaining optimal engine performance, efficiency, and emissions control. The pump’s advanced features, benefits, and compatibility with various Cummins engines make it a valuable asset for commercial truck fleets. Regular maintenance, proper installation, and timely troubleshooting are key to maximizing the performance and longevity of this part.

-

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles (Second Edition). SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.