This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

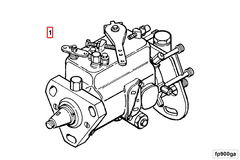

The Cummins 3280800 Fuel Injection Pump is a vital component in the operation of commercial trucks, playing a significant role in the fuel delivery system. This part ensures that the diesel engine receives the precise amount of fuel needed for efficient combustion, thereby contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of Fuel Injection Pumps

A Fuel Injection Pump is a device that delivers fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, the pump operates by pressurizing fuel and injecting it into the cylinders at high pressure, which leads to efficient combustion. The principles of fuel injection involve precise timing and pressure regulation, and the pump plays a key role in ensuring these parameters are met for optimal engine performance 2.

Purpose of the Cummins 3280800 Fuel Injection Pump

The Cummins 3280800 Fuel Injection Pump is designed to deliver fuel to the engine in a manner that enhances performance, fuel efficiency, and overall truck functionality. By providing the engine with the correct amount of fuel at the right time, this part contributes to smoother operation, increased power output, and better fuel economy. Its role is integral to maintaining the engine’s efficiency and reliability under various operating conditions 3.

Key Features

The Cummins 3280800 Fuel Injection Pump boasts several key features that enhance its performance and reliability. Its design incorporates high-quality construction materials that ensure durability and longevity. Additionally, the pump may include unique technological advancements such as precision metering and advanced fuel delivery systems. These features work together to provide consistent and reliable fuel injection, which is crucial for the engine’s operation.

Benefits

Using the Cummins 3280800 Fuel Injection Pump offers several benefits. These include improved fuel efficiency, enhanced engine performance, reduced emissions, and increased durability. The pump’s precise fuel delivery helps the engine operate more efficiently, leading to better fuel economy. Additionally, the reduction in emissions contributes to a cleaner environment, while the pump’s robust construction ensures long-lasting performance, which is beneficial for the overall operation of the truck.

Installation and Integration

Proper installation and integration of the Cummins 3280800 Fuel Injection Pump into a truck’s engine system are crucial for its effective operation. Compatibility with various engine models should be considered to ensure a seamless fit. The installation process involves several steps, including mounting the pump, connecting it to the fuel lines, and ensuring all connections are secure. Following manufacturer guidelines will help achieve a successful installation.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3280800 Fuel Injection Pump include fuel delivery problems, leaks, and performance inconsistencies. Troubleshooting these issues involves checking for proper installation, inspecting fuel lines for leaks, and ensuring the pump is receiving adequate power. Regular maintenance, such as inspecting and cleaning the pump, replacing worn-out parts, and performing routine checks, will help ensure its longevity and optimal performance.

Performance Optimization

To optimize the performance of the Cummins 3280800 Fuel Injection Pump, several strategies can be employed. These include tuning the pump for specific engine requirements, upgrading to higher-performance components, and making modifications to enhance its efficiency and effectiveness in the fuel delivery system. Regular maintenance and monitoring will also contribute to maintaining peak performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and components, with a long-standing reputation for innovation, quality, and customer satisfaction in the automotive industry. The company’s commitment to advancing technology and delivering reliable products has made it a trusted name among commercial vehicle operators. Cummins continues to push the boundaries of engine performance and efficiency, providing solutions that meet the demanding needs of modern transportation.

Cummins Fuel Injection Pump 3280800 Compatibility

The Cummins Fuel Injection Pump part number 3280800 is a critical component in the operation of several diesel engines. This part is designed to deliver precise fuel metering, ensuring optimal engine performance and efficiency.

Compatible Engines

- 4B3.9

- 5.9L Cummins Diesel Engines

The 3280800 fuel injection pump is engineered to fit seamlessly with the 4B3.9 engine. This compatibility ensures that the pump can effectively manage the fuel delivery system, providing the necessary pressure and timing for the engine to operate smoothly.

For the 5.9L Cummins Diesel Engines, the 3280800 fuel injection pump is also a perfect match. This engine variant is known for its robust performance and reliability, and the fuel injection pump plays a crucial role in maintaining these characteristics.

Installation and Functionality

When installing the 3280800 fuel injection pump, it is essential to follow the manufacturer’s guidelines to ensure proper alignment and connection. This pump is designed to integrate with the engine’s fuel system, providing the necessary fuel pressure and timing for efficient combustion.

The 3280800 fuel injection pump is engineered to deliver consistent fuel flow, which is critical for maintaining engine performance and reducing emissions. Its design allows for precise control over fuel delivery, ensuring that the engine operates at peak efficiency.

Performance and Reliability

The Cummins Fuel Injection Pump 3280800 is known for its durability and reliability. It is built to withstand the rigors of heavy-duty use, providing long-lasting performance without the need for frequent maintenance or replacement.

This fuel injection pump is a key component in the engine’s fuel system, and its performance directly impacts the overall efficiency and reliability of the engine. By ensuring that the pump is properly installed and maintained, engine operators can enjoy consistent performance and reduced downtime.

Role of Part 3280800 Fuel Injection Pump in Engine Systems

The Part 3280800 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with various components to ensure optimal fuel delivery and combustion.

Interaction with the Base Fuel Pump

The Base Fuel Pump serves as the primary mechanism for drawing fuel from the tank and delivering it to the fuel injection pump. The Part 3280800 Fuel Injection Pump receives pressurized fuel from the base fuel pump. It then further pressurizes the fuel to the levels required for injection into the combustion chambers. This high-pressure fuel is essential for achieving the fine mist necessary for efficient combustion.

Fuel Rail and Injectors

Once pressurized by the fuel injection pump, the fuel travels through the Fuel Rail. The fuel rail distributes the pressurized fuel to each of the Fuel Injectors. The fuel injection pump ensures that the fuel injectors receive a consistent and precise amount of fuel, which is critical for maintaining engine performance and fuel efficiency.

Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various engine parameters and adjusts the operation of the fuel injection pump accordingly. Sensors provide real-time data on engine load, speed, and other factors to the ECU. The ECU then sends signals to the fuel injection pump to modulate fuel delivery, ensuring that the engine operates within optimal parameters under varying conditions.

Combustion Chambers

Ultimately, the role of the Part 3280800 Fuel Injection Pump culminates in the Combustion Chambers. The finely atomized fuel injected by the injectors mixes with air and ignites, driving the pistons downward and converting chemical energy into mechanical work. The efficiency of this process is heavily dependent on the precise fuel delivery facilitated by the fuel injection pump.

Return System

Excess fuel not injected into the combustion chambers is returned to the fuel tank via the Return System. The fuel injection pump plays a role in managing this return flow, ensuring that fuel pressure remains within specified limits and that the system operates efficiently.

Conclusion

In summary, the Part 3280800 Fuel Injection Pump is a key component in the fuel delivery system, interacting with the base fuel pump, fuel rail, injectors, ECU, combustion chambers, and return system to ensure efficient and precise fuel delivery. Its role in maintaining engine performance, fuel efficiency, and reliability makes it an essential part of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.