This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

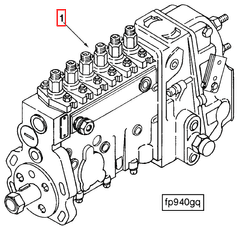

The Cummins 3280646 Fuel Injection Pump is a critical component in the commercial truck industry, essential for the efficient operation of diesel engines. This pump is engineered to deliver precise amounts of fuel to the engine’s combustion chambers, ensuring optimal engine performance and reliability. Its significance lies in enhancing the overall functionality of commercial trucks, making it a cornerstone in the industry.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers in a diesel engine. It operates based on fuel injection technology, where fuel is injected into the engine at high pressure and specific timings to optimize combustion. This process ensures efficient engine operation with minimal emissions and maximum power output. The pump’s role is essential in maintaining the balance between fuel delivery and engine demand 1.

Role of the 3280646 Fuel Injection Pump in Truck Operation

The 3280646 Fuel Injection Pump is integral to the operation of commercial trucks. It ensures that the engine receives the correct amount of fuel at the right time, which is vital for maintaining engine performance and fuel efficiency. By precisely controlling fuel delivery, the pump helps achieve optimal combustion, enhancing the truck’s overall efficiency and reducing emissions. Its role is particularly significant in heavy-duty applications where engine performance and reliability are paramount 2.

Key Features of the 3280646 Fuel Injection Pump

The 3280646 Fuel Injection Pump incorporates advanced technology to ensure precise fuel delivery. The pump consists of various components, including the plunger, cam, and delivery valve, each playing a specific role in the fuel injection process. Technological advancements in the pump’s design have led to improvements in durability, efficiency, and ease of maintenance, making it a reliable choice for commercial truck applications.

Benefits of Using the 3280646 Fuel Injection Pump

Utilizing the 3280646 Fuel Injection Pump offers several benefits. It contributes to improved fuel economy by ensuring efficient fuel use. The pump also enhances engine performance, providing consistent power output and reliability. Additionally, its robust design and advanced features contribute to the pump’s longevity and reduced maintenance requirements, making it a cost-effective solution for commercial truck operators.

Installation and Integration

When installing the 3280646 Fuel Injection Pump, it is important to follow manufacturer guidelines to ensure proper integration into the engine system. Careful attention to alignment, secure mounting, and correct connection of fuel lines and electrical components is necessary. Proper installation ensures that the pump operates efficiently and contributes to the overall performance of the engine.

Maintenance and Care

Routine maintenance of the 3280646 Fuel Injection Pump is crucial for ensuring optimal performance and longevity. Regular inspections, cleaning, and replacement of worn components are recommended. Adhering to the manufacturer’s maintenance schedule helps in identifying potential issues early and ensures that the pump continues to operate efficiently.

Troubleshooting Common Issues

Common issues with the 3280646 Fuel Injection Pump may include irregular fuel delivery, engine misfires, or decreased performance. Troubleshooting steps may involve checking for fuel leaks, inspecting the pump’s components for wear, and ensuring that the pump is properly aligned and mounted. Addressing these issues promptly can help maintain the pump’s efficiency and the engine’s performance.

Performance Optimization

To optimize the performance of the 3280646 Fuel Injection Pump, adjustments and upgrades may be considered. This can include fine-tuning the pump’s settings to match specific engine requirements or upgrading components for enhanced efficiency. Regular maintenance and keeping the pump clean also contribute to its optimal performance.

Compatibility with Cummins Engines

The Cummins Fuel Injection Pump part number 3280646 is designed to be compatible with a range of Cummins engines, ensuring precise fuel delivery and optimal performance. This part is engineered to fit seamlessly with the 6B5.9 engine, providing a reliable solution for maintaining the engine’s efficiency and power. Additionally, the 3280646 Fuel Injection Pump is also compatible with other Cummins engines within the same engine family, ensuring a standardized fit across multiple models.

For engines like the 6B5.9, the 3280646 Fuel Injection Pump is specifically tailored to meet the unique requirements of these power units. Its design allows for precise control over fuel delivery, which is crucial for maintaining the engine’s performance and longevity. The compatibility of this part with the 6B5.9 engine ensures that users can rely on consistent and dependable operation, minimizing the risk of downtime and maintenance issues.

Moreover, the 3280646 Fuel Injection Pump is part of a broader range of Cummins components that are engineered to work together, providing a cohesive and efficient system. This compatibility extends to other engines within the same family, ensuring that users can easily find and install the correct parts for their specific engine models. The standardization across these engines simplifies the maintenance process, allowing for quicker and more efficient repairs and upgrades.

Role of the 3280646 Fuel Injection Pump in Engine Systems

The 3280646 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with several key components to ensure optimal performance.

Integration with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the Fuel Injection Pump. The Fuel Injection Pump then takes over, precisely metering the fuel and delivering it to the injectors at the correct pressure and timing. This synergy ensures that the engine receives a consistent and controlled fuel supply, which is essential for combustion efficiency and overall engine performance.

Interaction with Fuel Injectors

Once the fuel is pressurized by the Fuel Injection Pump, it is distributed to the Fuel Injectors. These injectors atomize the fuel into a fine mist, allowing for better air-fuel mixture and more efficient combustion. The precise control offered by the Fuel Injection Pump ensures that the injectors operate within their optimal parameters, contributing to reduced emissions and improved fuel economy.

Coordination with Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in managing the operation of the Fuel Injection Pump. By receiving data from various sensors, the ECU adjusts the pump’s output to match the engine’s demands under different operating conditions. This real-time adjustment ensures that the engine operates efficiently across a wide range of speeds and loads.

Support from Fuel Filters

Fuel Filters are another component that works in tandem with the Fuel Injection Pump. These filters remove impurities from the fuel before it reaches the pump, ensuring that only clean fuel is pressurized and delivered to the injectors. This not only protects the Fuel Injection Pump from wear but also enhances the overall performance and longevity of the fuel system.

Contribution to Turbocharger Efficiency

In turbocharged engines, the Fuel Injection Pump also plays a role in supporting the Turbocharger. By providing a consistent and precise fuel supply, the pump helps maintain the air-fuel ratio necessary for the turbocharger to operate efficiently. This results in better throttle response and increased power output.

Conclusion

In summary, the 3280646 Fuel Injection Pump is a key component that interacts with various parts of the engine system to ensure efficient and reliable operation. Its role in metering and delivering fuel under precise control is fundamental to the performance and efficiency of modern engines. Regular maintenance, proper installation, and understanding its compatibility with Cummins engines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.