This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

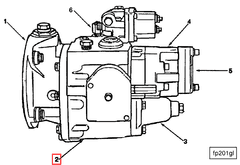

The Cummins 3279531 Fuel Pump Housing is a component designed for the fuel systems of heavy-duty trucks. Manufactured by Cummins Inc., a well-established name in the automotive and heavy-duty truck industries, this part is integral to the efficient operation of the truck’s engine.

Basic Concepts of Fuel Pump Housing

A fuel pump housing serves as the enclosure for the fuel pump and related components within the fuel system. Its primary function is to protect the internal parts from external contaminants and to maintain the structural integrity of the fuel pump assembly. Additionally, it plays a role in ensuring the proper flow and pressure of fuel to the engine, which is vital for consistent engine performance 1.

Role of the 3279531 Fuel Pump Housing in Truck Operation

The Cummins 3279531 Fuel Pump Housing is specifically engineered to fit within the fuel delivery system of trucks. It houses the fuel pump and other critical components, ensuring they are shielded from dirt, debris, and other contaminants that could impair their function. By maintaining a sealed environment, it helps in delivering fuel at the correct pressure and flow rate, which is necessary for the engine to operate efficiently 2.

Key Features of the 3279531 Fuel Pump Housing

The design and construction of the Cummins 3279531 Fuel Pump Housing incorporate several features that enhance its performance and durability. It is made from high-quality materials that are resistant to corrosion and wear, ensuring longevity. The housing is designed to provide a tight seal around the fuel pump, preventing leaks and maintaining the integrity of the fuel system. Additionally, its construction allows for easy installation and maintenance, which is beneficial for fleet operations.

Benefits of Using the 3279531 Fuel Pump Housing

Utilizing the Cummins 3279531 Fuel Pump Housing offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine under optimal conditions. The robust construction and high-quality materials used in its manufacture enhance its reliability and longevity, reducing the need for frequent replacements. Moreover, its design helps in maintaining consistent fuel pressure, which is crucial for the engine’s performance and efficiency 3.

Troubleshooting Common Issues with Fuel Pump Housings

Common issues with fuel pump housings can include leaks, contamination, and failure of the internal components. Symptoms of these problems may include engine misfires, reduced power, or difficulty starting the engine. Diagnostic procedures typically involve inspecting the housing for signs of wear, checking for leaks, and ensuring that the internal components are functioning correctly. Solutions may range from cleaning and repairing the housing to replacing it if damage is extensive.

Maintenance Tips for Fuel Pump Housings

Regular maintenance of the fuel pump housing is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the housing to remove any contaminants, and ensuring that all seals and connections are intact. Following the manufacturer’s recommended maintenance schedule can help in identifying potential issues before they lead to more significant problems.

Cummins Inc. Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Fuel Pump Housing (Part 3279531) Compatibility

The Cummins Fuel Pump Housing, part number 3279531, is a critical component designed to ensure efficient fuel delivery in various Cummins engine models. This part is engineered to fit seamlessly with the following engines:

- N14 MECHANICAL

In the N14 MECHANICAL engine, the fuel pump housing is integral to maintaining the engine’s performance. It houses the fuel pump, which is responsible for drawing fuel from the tank and delivering it to the engine at the required pressure. The housing’s design ensures that the fuel pump operates efficiently, contributing to the engine’s overall reliability and efficiency.

The Cummins Fuel Pump Housing is crafted with precision to ensure a perfect fit with the N14 MECHANICAL engine. Its robust construction and compatibility with this engine model make it an essential part for maintaining optimal engine function.

Understanding the Integration of Part 3279531 Fuel Pump Housing in Engine Systems

When examining the functionality of part 3279531, the Fuel Pump Housing, within various engine systems, it’s important to grasp how this component interacts with other elements to ensure efficient fuel delivery and engine performance.

Interaction with the Fuel Pump

The Fuel Pump Housing (part 3279531) serves as the enclosure for the fuel pump, providing a secure and sealed environment. This housing is designed to protect the fuel pump from contaminants and external damage, ensuring that the pump operates under optimal conditions. The housing also facilitates the mounting of the fuel pump within the fuel system, allowing for easy installation and maintenance.

Role in the Fuel Base Assembly

In conjunction with the fuel base, the Fuel Pump Housing plays a significant role in the structural integrity of the fuel system. The fuel base, which often includes components like the fuel filter and pressure regulator, relies on the housing to maintain a consistent fuel flow. The housing’s design ensures that the fuel base components are aligned correctly, promoting efficient fuel delivery to the engine.

Contribution to the EBM System

Within the Engine Bay Module (EBM) system, the Fuel Pump Housing is integral to the operation of the fuel pump and the overall fuel delivery system. The EBM system often includes a variety of sensors and control units that monitor fuel pressure and flow. The housing’s role in protecting these sensitive components from environmental factors is essential for the accurate functioning of the EBM system.

Ensuring Consistent Fuel Delivery

The consistent delivery of fuel is paramount for engine performance, and the Fuel Pump Housing contributes significantly to this process. By housing the fuel pump and integrating with the fuel base, it ensures that fuel is delivered at the correct pressure and volume. This consistent fuel delivery is vital for the engine’s combustion process, directly impacting its efficiency and power output.

Facilitating Maintenance and Repairs

From a maintenance perspective, the Fuel Pump Housing simplifies the process of accessing and replacing the fuel pump. Its design allows for straightforward removal and installation, reducing downtime during repairs or maintenance checks. This ease of access is beneficial for both routine maintenance and emergency repairs, ensuring that the engine system remains operational with minimal interruption.

Conclusion

In summary, part 3279531 Fuel Pump Housing is a key component in the engine’s fuel system, interacting closely with the fuel pump, fuel base, and EBM system to ensure efficient and reliable fuel delivery. Its role in protecting and facilitating the operation of these components is essential for maintaining engine performance and facilitating ease of maintenance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.