This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fuel Drain Tube 3176387, manufactured by Cummins, is a component designed for use in heavy-duty trucks. Cummins, a well-established name in the automotive and heavy-duty truck industries, produces a range of parts and systems that contribute to the efficiency, reliability, and safety of vehicles. This Cummins part is significant in the context of heavy-duty truck maintenance and operation, providing a means to safely and effectively drain fuel from the system when necessary.

Purpose of the Fuel Drain Tube 3176387

The Fuel Drain Tube 3176387 serves a specific function within the fuel system of heavy-duty trucks. It facilitates the draining of fuel for maintenance purposes or in emergency situations where fuel removal is required. This component ensures that the fuel system can be safely depressurized and drained, which is important for both routine maintenance and addressing potential issues within the fuel system 1.

Key Features

The design and construction of the Fuel Drain Tube 3176387 incorporate several features that enhance its performance and durability. It is made from materials that are resistant to the corrosive effects of fuel, ensuring longevity. The tube features secure connection types that prevent leaks and ensure a tight fit within the fuel system. Additionally, unique attributes such as reinforced sections or specialized coatings may be included to further improve its resilience and functionality 2.

Benefits

The Fuel Drain Tube 3176387 offers several advantages. It contributes to improved safety during fuel system maintenance by providing a controlled and secure method for draining fuel. This reduces the risk of spills and exposure to flammable materials. The component also enhances system reliability by ensuring that the fuel system can be properly maintained and serviced. Furthermore, its design allows for ease of use, making the draining process more straightforward for technicians 3.

Installation Process

Proper installation of the Fuel Drain Tube 3176387 is crucial for its effective operation. The process involves several steps, including preparing the fuel system by depressurizing it and ensuring that all connections are clean and free from debris. Tools required may include wrenches for securing connections and possibly a fuel system depressurization tool. Best practices include following the manufacturer’s guidelines for torque specifications and ensuring that all connections are tight and secure to prevent leaks 4.

Troubleshooting Common Issues

Common problems associated with fuel drain tubes, such as leaks or blockages, can often be traced back to installation errors or wear and tear. Troubleshooting steps may include inspecting connections for tightness, checking for signs of wear or damage on the tube itself, and ensuring that the fuel system is properly depressurized before attempting to drain fuel. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

Regular maintenance of the Fuel Drain Tube 3176387 is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the tube and its connections as part of routine fuel system maintenance can also help prevent issues. Following manufacturer recommendations for inspection intervals and maintenance procedures will contribute to the overall reliability of the fuel system.

Safety Considerations

When working with the Fuel Drain Tube 3176387, it is important to follow safety protocols to protect against the hazards associated with flammable materials. This includes ensuring proper ventilation when working on the fuel system, using appropriate personal protective equipment, and adhering to all safety guidelines provided by Cummins. Handling fuel with care and being aware of the potential risks can help prevent accidents and ensure a safe working environment.

Cummins Corporation

Cummins Corporation is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves the automotive and heavy-duty truck industries with a wide range of products designed to enhance vehicle performance, efficiency, and reliability. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Application in Cummins Engines

The Fuel Drain Tube (part number 3176387) is compatible with several Cummins engine models. These engines include, but are not limited to, the following:

-

K38 Series: This series of engines is known for its robust design and reliability, often used in heavy-duty applications. The fuel drain tube in these engines ensures that contaminants are effectively removed from the fuel, preventing potential damage to the engine’s fuel system components.

-

Other Cummins Engines: While the K38 series is a notable application, the fuel drain tube is also used in various other Cummins engines. Its design and functionality remain consistent across different engine models, providing a reliable solution for fuel system maintenance.

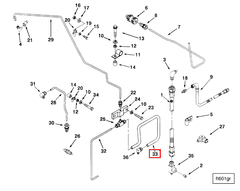

Role of Part 3176387 Fuel Drain Tube in Engine Systems

The part 3176387 Fuel Drain Tube is an essential component in the fuel system of various engine setups. It is designed to facilitate the safe and efficient drainage of fuel from the system, ensuring that any excess or contaminated fuel is removed without compromising the integrity of the fuel supply.

In conjunction with fuel tubing, the Fuel Drain Tube plays a significant role in maintaining the overall efficiency and safety of the engine. The fuel tubing transports fuel from the tank to the engine, and the Fuel Drain Tube provides a controlled means to remove fuel when necessary. This is particularly important during maintenance procedures, where draining the fuel system is required to prevent contamination or to perform repairs.

The integration of the Fuel Drain Tube with the fuel tubing ensures that the drainage process is streamlined. When the Fuel Drain Tube is activated, it allows fuel to flow out of the system through a designated path, which is often connected to a collection container to capture the drained fuel. This setup prevents fuel spillage and ensures that the drainage process is contained and manageable.

Additionally, the Fuel Drain Tube works in harmony with other components such as the fuel filter and fuel pump. By efficiently draining the fuel system, it helps in maintaining the cleanliness of the fuel filter, ensuring that it can effectively trap contaminants. A clean fuel filter, in turn, allows the fuel pump to operate more efficiently, delivering a consistent fuel supply to the engine.

Conclusion

The Fuel Drain Tube 3176387 by Cummins is a vital component in the maintenance and operation of heavy-duty trucks. Its design and functionality ensure safe and efficient fuel drainage, contributing to the overall reliability and safety of the fuel system. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring that the fuel system remains clean and efficient.

-

Tyres Suspension and Handling Second Edition, John C Dixon, SAE International, 1996

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.