This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

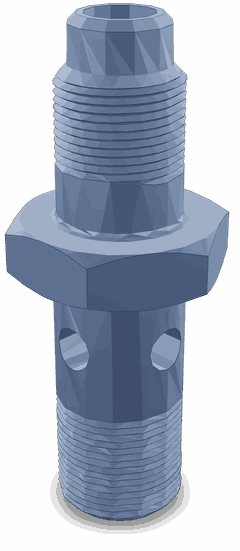

The Cummins 3164614 Fuel Pump Tester is a specialized diagnostic tool designed for the maintenance and operation of commercial trucks. It is used to evaluate the performance of fuel pumps, ensuring they operate within the required specifications for efficient engine operation. This tester plays a significant role in maintaining the reliability and performance of diesel engines in commercial vehicles.

Basic Concepts of Fuel Pump Testers

A fuel pump tester is a device used to diagnose and ensure the proper operation of fuel pumps in diesel engines. It works by simulating the conditions under which the fuel pump operates, allowing technicians to assess its performance. The tester measures various parameters such as flow rate, pressure, and delivery volume, providing valuable data that helps in identifying any issues with the fuel pump. This diagnostic tool is integral to maintaining the efficiency and reliability of the fuel system in diesel engines 1.

Purpose of the Cummins 3164614 Fuel Pump Tester

The Cummins 3164614 Fuel Pump Tester is specifically designed to test the performance of fuel pumps in trucks. It ensures that the fuel pump meets the necessary specifications for efficient engine operation. By using this tester, technicians can identify any deviations from the expected performance, allowing for timely maintenance or replacement of the fuel pump. This helps in maintaining the overall efficiency and reliability of the truck’s engine 2.

Key Features

The Cummins 3164614 Fuel Pump Tester is equipped with several key features that enhance its functionality and ease of use. Its design includes components such as a pressure gauge, flow meter, and control valves, which allow for precise measurement and simulation of fuel pump operations. The tester is built to be durable and reliable, ensuring consistent performance over time. Additionally, its user-friendly interface makes it easy for technicians to operate and interpret the results.

Benefits

Using the Cummins 3164614 Fuel Pump Tester offers several benefits. It provides improved diagnostic accuracy, allowing technicians to identify and address issues with the fuel pump more effectively. This leads to enhanced engine performance, as the fuel pump is ensured to operate within the required specifications. Furthermore, the use of this tester contributes to the increased reliability of fuel system components, reducing the likelihood of unexpected failures and downtime 3.

Troubleshooting and Maintenance

To ensure the Cummins 3164614 Fuel Pump Tester remains in optimal working condition, regular maintenance and troubleshooting procedures should be followed. This includes performing routine checks on the tester’s components, such as the pressure gauge and flow meter, to ensure they are functioning correctly. Identifying and addressing any issues promptly can help maintain the accuracy and reliability of the tester. Additionally, keeping the tester clean and stored in a suitable environment will contribute to its longevity and performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines, natural gas engines, and related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality automotive components and testing equipment. The company’s commitment to innovation and excellence is reflected in its products, which are designed to meet the demanding requirements of commercial and industrial applications.

Role of Part 3164614 Fuel Pump Tester in Engine Systems

The 3164614 Fuel Pump Tester is an essential tool for diagnosing and ensuring the optimal performance of fuel systems in various engine setups. When integrated with a Fuel System Leak Test Kit, it allows for a comprehensive evaluation of the fuel delivery system, identifying any leaks or inefficiencies that could compromise engine performance. This synergy between the tester and the leak test kit ensures that any discrepancies in fuel pressure or delivery are promptly detected and addressed.

In conjunction with a Fuel System Leak Tester, the 3164614 Fuel Pump Tester provides a detailed analysis of the fuel system’s integrity. This combination is particularly beneficial in pinpointing the exact location of leaks, whether they originate from the fuel lines, injectors, or the pump itself. Such precise diagnostics are invaluable for maintaining engine efficiency and reliability.

When used alongside a Service Tool Kit, the Fuel Pump Tester enhances the mechanic’s ability to perform thorough maintenance and repairs. The service tool kit typically includes a variety of instruments and gauges that, when paired with the tester, facilitate a more streamlined and effective troubleshooting process. This integration ensures that all aspects of the fuel system are examined, from pressure levels to flow rates, contributing to a more robust engine performance.

Furthermore, the Tool Certification Kit plays a significant role in validating the accuracy and reliability of the Fuel Pump Tester. By certifying the tool, mechanics can be confident in the precision of their diagnostics, ensuring that any adjustments or repairs made to the fuel system are based on accurate data. This certification process is essential for maintaining the high standards of engine performance and safety.

Conclusion

In summary, the Cummins 3164614 Fuel Pump Tester, when used in tandem with complementary components such as the Fuel System Leak Test Kit, Fuel System Leak Tester, Service Tool Kit, and Tool Certification Kit, offers a comprehensive solution for diagnosing and maintaining fuel systems. This integrated approach not only enhances the efficiency of engine diagnostics but also ensures that any issues are addressed with precision and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.