This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3094785 Idler Shaft is a component designed for use in heavy-duty trucks. It contributes to the efficient and reliable functioning of the engine system. Understanding its purpose and functionality is essential for maintaining the overall performance and longevity of the truck.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component that supports and guides belts or chains within a system. Its function is to maintain proper tension and alignment of these components, ensuring they operate smoothly and efficiently. In the context of a truck’s drivetrain, the idler shaft facilitates the transfer of power and motion between various engine components 1.

Purpose of the Cummins 3094785 Idler Shaft

The Cummins 3094785 Idler Shaft maintains the correct tension on belts that drive accessories such as the alternator, water pump, and air conditioning compressor. This ensures that these components operate efficiently and reduces the likelihood of belt slippage or failure. Additionally, the idler shaft contributes to the smooth operation of the engine by supporting the belt system and minimizing vibrations 2.

Key Features

The Cummins 3094785 Idler Shaft is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions of heavy-duty truck operation. Key features include a precision-machined bearing surface for smooth rotation, durable construction materials that resist wear and corrosion, and a design that allows for easy installation and maintenance 3.

Benefits of Using the Cummins 3094785 Idler Shaft

Incorporating the Cummins 3094785 Idler Shaft into a truck’s engine system offers several advantages. It contributes to improved efficiency by ensuring that belts remain properly tensioned and aligned. This reduces wear on other components and enhances the reliability of the engine system. Additionally, the durable construction of the idler shaft supports long-term performance and reduces the need for frequent replacements 4.

Installation and Integration

Proper installation of the Cummins 3094785 Idler Shaft is crucial for its effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines to ensure optimal performance. This may involve aligning the shaft with other components, securing it in place, and verifying that belts are correctly tensioned. Careful attention to these details during installation helps prevent issues down the line 5.

Troubleshooting Common Issues

Common problems associated with idler shafts include noise, vibration, or belt slippage. These issues can often be traced back to improper installation, wear and tear, or misalignment. Diagnostic steps for addressing these problems may involve inspecting the shaft and surrounding components for signs of damage or wear, ensuring that the shaft is properly aligned and tensioned, and making any necessary adjustments or replacements 6.

Maintenance Tips

Routine maintenance is key to ensuring the longevity and optimal performance of the Cummins 3094785 Idler Shaft. This includes regular inspection of the shaft and associated belts for signs of wear or damage, ensuring that belts remain properly tensioned, and replacing the idler shaft according to the manufacturer’s recommended intervals or as needed based on condition. Adhering to these maintenance practices helps prevent unexpected failures and supports the efficient operation of the truck’s engine system 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding needs of commercial vehicles and industrial applications.

Compatibility of Cummins 3094785 Idler Shaft with Cummins Engines

The Cummins 3094785 Idler Shaft is designed to work seamlessly with several Cummins engine models, ensuring smooth operation and longevity. This part is compatible with various engine configurations, including:

- QST30 CM552 Engines: Specifically engineered to fit within the QST30 CM552 engine series, known for its robust performance and reliability.

- Industrial Engines: Designed to fit engines used in industrial settings, where reliability and durability are paramount.

- Marine Engines: Engineered to withstand the harsh conditions of saltwater environments, ensuring that the engine’s timing components remain properly aligned.

- Agricultural Engines: Crucial for maintaining the timing belt’s tension and alignment in agricultural machinery, ensuring efficient and reliable engine operation.

By understanding the compatibility of the Cummins 3094785 Idler Shaft with various Cummins engine models, technicians and operators can ensure that their engines remain in optimal condition, reducing downtime and maintenance costs.

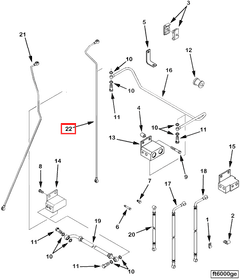

Role of Cummins 3094785 Idler Shaft in Plumbing and Fuel Systems

The Cummins 3094785 Idler Shaft is an integral component in both plumbing and fuel systems, ensuring the smooth operation and efficiency of these systems.

Plumbing Systems

In plumbing systems, the Cummins 3094785 Idler Shaft maintains tension in the belts that drive various pumps. This ensures that the pumps operate efficiently, providing consistent water flow and pressure. The idler shaft helps in reducing wear and tear on the belts by keeping them properly aligned and tensioned.

Fuel Systems

In fuel systems, the Cummins 3094785 Idler Shaft maintains the tension in the belts that drive fuel pumps. This is essential for ensuring a steady fuel supply to the engine, which is vital for consistent engine performance. The idler shaft helps in reducing the strain on the fuel pump belts, thereby extending their lifespan and ensuring that the fuel system operates smoothly.

By integrating the Cummins 3094785 Idler Shaft into these systems, engineers and mechanics can ensure that both plumbing and fuel systems operate efficiently, reducing the likelihood of system failures and improving overall performance.

Conclusion

The Cummins 3094785 Idler Shaft plays a vital role in the operation of heavy-duty trucks by maintaining the tension and alignment of belts that drive critical engine components. Its robust design and durable construction ensure long-term performance and reliability. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are essential for maximizing the benefits of this part. Additionally, its application in plumbing and fuel systems highlights its versatility and importance in ensuring the efficient operation of these systems.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388579.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.