3094776

Fuel Transfer Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3094776 Fuel Transfer Tube is a critical component in heavy-duty trucks, designed to facilitate the transfer of fuel from the tank to the engine. This part ensures a consistent and reliable fuel supply, which is essential for the truck’s performance and efficiency 3.

Basic Concepts of Fuel Transfer Tubes

A Fuel Transfer Tube is a conduit in a truck’s fuel system that allows for the movement of fuel from the storage tank to the engine. It channels fuel under pressure, ensuring the engine receives the necessary amount for combustion. This process is fundamental to the efficient functioning of the vehicle, directly impacting the engine’s performance and the truck’s overall operational efficiency 2.

Purpose of the Cummins 3094776 Fuel Transfer Tube

The Cummins 3094776 Fuel Transfer Tube is engineered to transfer fuel from the tank to the engine in heavy-duty trucks. It maintains a steady fuel flow, which is essential for the engine’s consistent operation. By ensuring efficient fuel delivery, this component contributes to the truck’s reliability and performance under various operating conditions 3.

Key Features

This Cummins part is constructed from durable materials that resist the corrosive effects of fuel. Its design includes precise engineering for a secure fit within the fuel system and smooth internal surfaces to facilitate efficient fuel flow. These attributes contribute to the tube’s longevity and reliability in demanding applications 1.

Benefits

The use of the Cummins 3094776 Fuel Transfer Tube offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine without unnecessary loss or leakage. Its reliable performance reduces the likelihood of fuel system failures, enhancing the truck’s overall reliability. Additionally, the tube’s durable construction supports its longevity, providing value over the truck’s operational life 3.

Installation Process

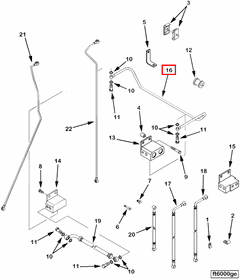

Installing the Cummins 3094776 Fuel Transfer Tube requires careful attention to detail. The process involves securing the tube within the fuel system, ensuring all connections are tight and secure to prevent leaks. Tools such as wrenches and sealants may be required, and it is important to follow manufacturer guidelines to ensure proper installation. Precautions should be taken to avoid damage to the tube or surrounding components during installation 2.

Common Issues and Troubleshooting

Fuel Transfer Tubes may encounter issues such as leaks or blockages over time. Identifying these problems early is important for maintaining the truck’s performance. Troubleshooting methods may include visual inspections for leaks, checking for obstructions within the tube, and ensuring all connections are secure. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the fuel system 1.

Maintenance Tips

Regular maintenance of the Cummins 3094776 Fuel Transfer Tube is important for its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any buildup that could impede fuel flow, and ensuring all connections remain tight. Adhering to these maintenance practices can help prevent issues and ensure the tube continues to function efficiently 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range includes engines for on-highway, off-highway, and power generation applications, demonstrating its commitment to providing reliable and efficient power solutions 3.

Cummins Fuel Transfer Tube 3094776 Compatibility

The Cummins Fuel Transfer Tube part number 3094776 is designed to fit seamlessly within a variety of Cummins engines, ensuring efficient fuel transfer and maintaining the integrity of the fuel system. This part is crucial for the proper functioning of the engines it is compatible with, as it facilitates the movement of fuel from the tank to the engine, ensuring consistent performance and reliability 3.

QST30 CM552 Engines

The Cummins Fuel Transfer Tube 3094776 is specifically engineered to integrate with the QST30 CM552 engines. These engines are known for their robust design and are often used in heavy-duty applications where durability and performance are paramount. The fuel transfer tube ensures that the fuel is delivered smoothly and efficiently, reducing the risk of fuel starvation and enhancing overall engine efficiency 3.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the Cummins Fuel Transfer Tube 3094776 is also compatible with other similar Cummins engines. These engines share common design principles and fuel system architectures, making the part interchangeable across various models. This compatibility ensures that users can maintain their engines with confidence, knowing that the fuel transfer tube will fit and function as intended 3.

Role of Part 3094776 Fuel Transfer Tube in Engine Systems

The part 3094776 Fuel Transfer Tube is an integral component in the fuel system of various engine setups. Its primary function is to facilitate the movement of fuel from one location to another within the engine system, ensuring a consistent and reliable fuel supply to the engine’s combustion chambers 3.

Integration with Fuel System Components

-

Fuel Tank to Fuel Pump: The Fuel Transfer Tube connects the fuel tank to the fuel pump. This connection is vital for drawing fuel from the tank and pressurizing it for delivery to the engine. The tube must be securely fitted to prevent leaks and ensure that fuel flow is uninterrupted 2.

-

Fuel Pump to Fuel Filter: After the fuel is pressurized by the pump, it travels through the Fuel Transfer Tube to the fuel filter. This tube ensures that pressurized fuel reaches the filter without loss of pressure, allowing the filter to effectively remove impurities from the fuel before it reaches the engine 1.

-

Fuel Filter to Fuel Injectors: Post-filtration, the clean fuel moves through another segment of the Fuel Transfer Tube to the fuel injectors. This ensures that the injectors receive a steady and clean fuel supply, which is essential for precise fuel delivery to the combustion chambers 3.

-

Fuel Return Line: In some engine systems, excess fuel not used by the injectors is returned to the fuel tank via a return line. The Fuel Transfer Tube in this application helps manage the flow of returned fuel, maintaining system pressure and temperature stability 2.

Interaction with Plumbing Components

The Fuel Transfer Tube also interacts with various plumbing components within the engine system:

-

Fittings and Connectors: The tube is often connected to fittings and connectors that link different sections of the fuel system. These connections must be tight and secure to prevent fuel leaks, which could pose safety hazards 1.

-

Hoses and Lines: In conjunction with hoses and lines, the Fuel Transfer Tube forms a continuous pathway for fuel movement. It is designed to withstand the pressure and temperature variations within the fuel system, ensuring durable and reliable performance 3.

-

Seals and Gaskets: To maintain the integrity of the fuel system, the Fuel Transfer Tube is typically paired with seals and gaskets at connection points. These components help create a leak-proof system, essential for safe and efficient engine operation 2.

Conclusion

In summary, the Cummins 3094776 Fuel Transfer Tube plays a significant role in the seamless operation of the fuel system by ensuring consistent fuel flow, pressure maintenance, and system integrity. Its integration with various fuel and plumbing components underscores its importance in engine performance and reliability 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.