This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

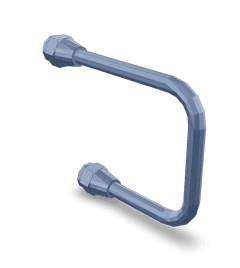

The Fuel Drain Tube (Part #3064668) manufactured by Cummins is a component designed to facilitate the safe and efficient drainage of fuel from the fuel system of commercial trucks. Its role is significant in maintaining the operational integrity and safety of the vehicle’s fuel system 1.

Basic Concepts of Fuel Drain Tubes

A fuel drain tube is a component within the fuel system that allows for the controlled release of fuel. This process is vital for maintenance procedures, such as fuel filter changes, and for ensuring that the fuel system remains free of contaminants. The tube operates by providing a pathway for fuel to exit the system under controlled conditions, which helps in maintaining the efficiency and safety of the fuel management system in heavy-duty trucks 2.

Purpose of the Fuel Drain Tube

This Cummins part plays a role in the fuel system by enabling the safe and efficient drainage of fuel. This function is important for routine maintenance tasks, such as draining fuel prior to servicing the fuel filter or other components. By facilitating the removal of fuel, the tube contributes to the overall engine performance and reliability by ensuring that the fuel system remains clean and free of contaminants.

Key Features

The Fuel Drain Tube is characterized by its robust design and the materials used in its construction, which are selected to withstand the demands of heavy-duty truck environments. Its design includes features that enhance its performance and durability, ensuring it can operate effectively under various conditions.

Benefits

Using the Fuel Drain Tube is associated with several benefits. These include improved fuel system efficiency through the removal of contaminants, enhanced safety during maintenance procedures by allowing for controlled fuel drainage, and reduced maintenance requirements due to its durable construction and design.

Installation Process

Installing the Fuel Drain Tube involves several steps to ensure it is correctly fitted. This process includes preparing the area for installation, using the appropriate tools and equipment, and following the manufacturer’s guidelines to secure the tube in place. Proper installation is important to ensure the tube functions as intended and contributes to the safe and efficient operation of the fuel system.

Troubleshooting Common Issues

Common issues with the Fuel Drain Tube may include leaks or blockages. Troubleshooting these problems involves inspecting the tube for signs of damage or wear, ensuring it is correctly installed, and addressing any issues that could affect its performance. Solutions may range from simple adjustments to replacement of the tube if necessary.

Maintenance Tips

Maintaining the Fuel Drain Tube involves regular inspection for signs of wear or damage, cleaning as needed to remove any buildup that could affect its operation, and following the manufacturer’s recommendations for replacement. These practices help ensure the tube continues to perform effectively and contributes to the longevity of the fuel system.

Safety Considerations

When working with the Fuel Drain Tube, it is important to follow safety guidelines and precautions. This includes ensuring the fuel system is depressurized before beginning any work, using appropriate personal protective equipment, and adhering to the manufacturer’s recommendations for handling and installation. These measures are important to ensure the safety of personnel and the proper functioning of the fuel system.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to producing high-quality components for commercial vehicles. With a history of innovation and excellence in the automotive industry, Cummins has established a reputation for reliability and performance in its products, including the Fuel Drain Tube 3.

Compatibility

The Fuel Drain Tube, part number 3064668, is designed to facilitate the removal of water and sediment from the fuel tank, ensuring the engine operates smoothly and efficiently. Below is a detailed description of how this part fits with specific Cummins engines.

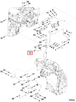

V903 Engine Group

The V903 engine series is known for its robust design and reliability, often used in heavy-duty applications. The Fuel Drain Tube is engineered to fit seamlessly within the fuel system architecture of the V903 engines. This part is typically located at the lowest point of the fuel tank, allowing it to effectively drain accumulated water and contaminants. The design ensures that the tube is securely attached to the tank, preventing leaks and maintaining the integrity of the fuel system.

In the V903 engines, the fuel drain tube is an integral part of the maintenance routine. Regular inspection and replacement of this component are essential to prevent fuel contamination, which can lead to engine performance issues and increased maintenance costs. The tube’s placement and design ensure that it can efficiently handle the demands of the engine’s operation, contributing to overall system reliability and longevity.

Role of Part 3064668 Fuel Drain Tube in Engine Systems

The Fuel Drain Tube (Part 3064668) is an essential component in the fuel system of an engine, facilitating the safe and efficient drainage of fuel when necessary. This component is integrated into the system in conjunction with several other key parts to ensure optimal performance and safety.

Integration with Fuel System Components

-

Fuel Drain Tubing Mounting: The Fuel Drain Tube is securely mounted using the Fuel Drain Tubing Mounting hardware. This ensures that the tube is properly positioned and supported within the engine compartment, allowing for effective drainage without the risk of detachment or misalignment.

-

Fuel Tubing: The Fuel Drain Tube connects to the main fuel tubing network. This connection point is typically located at a low point in the fuel system to allow for the collection and removal of fuel. The tube is designed to interface seamlessly with the fuel tubing, ensuring a leak-free connection that maintains the integrity of the fuel system.

-

Plumbing: Within the broader context of engine plumbing, the Fuel Drain Tube plays a role in the overall fuel management strategy. It is part of a network that includes various plumbing components such as hoses, fittings, and valves. The tube’s placement and design are critical to ensuring that fuel can be drained efficiently without interfering with the regular flow of fuel to the engine.

-

Fuel Supply System: The Fuel Drain Tube is an auxiliary component within the fuel supply system. While the primary role of the fuel supply system is to deliver fuel to the engine, the drain tube provides a necessary function for maintenance and safety. It allows for the removal of fuel during servicing or in emergency situations, helping to prevent fuel contamination and ensuring that the fuel supply remains clean and uncompromised.

Conclusion

In summary, the Fuel Drain Tube (Part 3064668) is a vital element in the fuel system, working in tandem with fuel drain tubing mounting, fuel tubing, plumbing, and the fuel supply system to ensure the engine operates efficiently and safely.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Cummins Inc. Company Overview. Available at: Cummins Official Website (Accessed: 10 March 2024).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.