This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

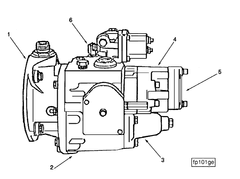

The Cummins 3059625 Fuel Pump is a component designed for use in commercial trucks. It plays a role in the fuel delivery system, ensuring that the engine receives the necessary fuel for optimal performance. Understanding its function and importance can help in maintaining and enhancing the efficiency of truck operations.

Basic Concepts of Fuel Pumps

A fuel pump is a device that moves fuel from the tank to the engine. It ensures that the engine receives a consistent supply of fuel under various operating conditions. Fuel pumps can be mechanical, electric, or high-pressure types, each serving specific functions within the engine system. Mechanical fuel pumps are driven by the engine’s camshaft, while electric fuel pumps are powered by the vehicle’s electrical system. High-pressure fuel pumps, like the Cummins 3059625, are designed to deliver fuel at higher pressures required by modern diesel engines 1.

Role of the Cummins 3059625 Fuel Pump in Truck Operation

The Cummins 3059625 Fuel Pump contributes to the efficient operation of a truck by ensuring precise fuel delivery to the engine. It operates at high pressures, which is crucial for the combustion process in diesel engines. This pump helps maintain consistent fuel pressure, which is vital for engine performance, especially under varying load conditions. Its role in fuel delivery directly impacts the engine’s efficiency and power output 2.

Key Features

The Cummins 3059625 Fuel Pump is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological aspects to ensure reliable operation. The pump is engineered to withstand the high pressures and temperatures associated with diesel fuel systems. Its design includes precision-machined components to ensure accurate fuel delivery and minimal leakage.

Benefits of Using the Cummins 3059625 Fuel Pump

Using the Cummins 3059625 Fuel Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine receives the optimal amount of fuel. The pump’s reliable operation enhances the overall durability and reliability of the truck’s fuel system. Additionally, its high-pressure capabilities support better engine performance and reduced emissions 3.

Installation and Integration

Proper installation of the Cummins 3059625 Fuel Pump involves several steps to ensure it functions correctly within the truck’s fuel system. It is important to follow manufacturer guidelines for installation, including any necessary preparations such as cleaning the fuel system and checking for leaks. Integration with other truck systems, such as the engine control unit, is also crucial for optimal performance.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3059625 Fuel Pump. This includes periodic inspections for leaks, checking fuel pressure, and ensuring that all connections are secure. Troubleshooting tips may involve checking for consistent fuel pressure, listening for unusual noises, and addressing any signs of fuel leakage promptly.

Common Issues and Solutions

Frequent problems associated with fuel pumps, including the Cummins 3059625, can include fuel leaks, inconsistent fuel pressure, and pump failure. Solutions may involve replacing worn-out components, ensuring proper installation, and conducting regular maintenance checks. Addressing these issues promptly can prevent more significant problems and ensure the fuel pump operates efficiently.

Performance Enhancements

Potential upgrades or modifications to the Cummins 3059625 Fuel Pump can enhance truck performance. This may include installing higher-capacity fuel filters, upgrading to a more efficient fuel line, or modifying the pump for increased fuel pressure. These enhancements can lead to improved engine performance and fuel efficiency.

Safety Considerations

When working with the Cummins 3059625 Fuel Pump, it is important to observe safety guidelines and precautions to prevent accidents and ensure safe operation. This includes working in a well-ventilated area, avoiding sparks or open flames near the fuel system, and wearing appropriate personal protective equipment. Following these safety measures helps protect both the operator and the equipment.

Environmental Impact

The use of the Cummins 3059625 Fuel Pump can have positive environmental implications. By ensuring efficient fuel delivery, it contributes to improved fuel efficiency and reduced fuel consumption. This, in turn, can lead to lower emissions and a smaller environmental footprint. The pump’s reliable operation supports these environmental benefits by maintaining optimal engine performance.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company offers a diverse product range, including engines, filtration systems, and fuel systems, designed to meet the needs of various industries and applications.

Role of Part 3059625 Fuel Pump in Engine Systems

The part 3059625 fuel pump is a component in the fuel delivery system of an engine. Its primary function is to draw fuel from the fuel tank and deliver it to the engine’s fuel injectors or carburetor under the required pressure. This ensures a consistent and adequate fuel supply for combustion.

Integration with Fuel Injectors

In modern engines equipped with fuel injection systems, the 3059625 fuel pump works in tandem with the fuel injectors. The pump pressurizes the fuel, which is then precisely sprayed into the combustion chamber by the injectors. This pressurized delivery allows for fine-tuned fuel atomization, enhancing combustion efficiency and overall engine performance.

Coordination with the Fuel Filter

Before the fuel reaches the injectors, it passes through the fuel filter. The 3059625 fuel pump ensures that the fuel maintains sufficient pressure to flow through the filter, removing any contaminants that could otherwise damage the injectors or other sensitive components within the fuel system.

Interaction with the Fuel Pressure Regulator

The fuel pressure regulator maintains a consistent fuel pressure within the system. The 3059625 fuel pump supplies the necessary pressure, and the regulator modulates it to ensure that the fuel injectors receive a steady flow, optimizing engine performance across various operating conditions.

Role in Carbureted Engines

In engines with carburetors, the 3059625 fuel pump still plays a vital role. It provides the necessary fuel pressure to ensure that the carburetor can atomize the fuel properly before it enters the combustion chamber. This is essential for maintaining the correct air-fuel mixture, which is critical for efficient combustion and engine operation.

Support for the Fuel Tank Sending Unit

The fuel pump often integrates with the fuel tank sending unit, which measures the fuel level in the tank. The 3059625 fuel pump’s consistent operation ensures that the sending unit can accurately report fuel levels, aiding in fuel management and preventing unexpected fuel depletion.

Contribution to Engine Control Unit (ECU) Functionality

In fuel-injected engines, the engine control unit (ECU) relies on consistent fuel pressure to manage the air-fuel ratio accurately. The 3059625 fuel pump provides this stability, allowing the ECU to make real-time adjustments for optimal engine performance, fuel efficiency, and emissions control.

Conclusion

The Cummins 3059625 Fuel Pump is a critical component in the fuel delivery system of commercial trucks. Its role in ensuring consistent and adequate fuel supply under high pressure is vital for engine performance and efficiency. Proper installation, regular maintenance, and understanding its integration with other engine systems are essential for maximizing its benefits and ensuring the longevity of the truck’s fuel system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.