This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Fuel Bypass Tube (Part #3053751) manufactured by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. Its purpose is to manage fuel flow within the system, ensuring that the engine receives a consistent supply of fuel under varying conditions. This part plays a significant role in maintaining the performance and reliability of the truck’s fuel system 1.

Basic Concepts of Fuel Bypass Tubes

A Fuel Bypass Tube is a component within the fuel system that allows excess fuel to return to the tank or be redirected as needed. Its function is to maintain optimal fuel pressure and prevent fuel starvation, which can occur under high-demand conditions. The tube operates by providing an alternative path for fuel when the primary fuel lines are under stress, ensuring that the engine continues to receive the necessary fuel supply for efficient operation 2.

Role of the Fuel Bypass Tube in Truck Operation

The Fuel Bypass Tube plays a role in the overall operation of a truck by interacting with other fuel system components such as the fuel pump, injectors, and fuel lines. It contributes to engine performance by ensuring that fuel pressure remains within the desired range, which is crucial for the proper functioning of fuel injectors and overall engine efficiency. The tube’s ability to manage fuel flow under different operating conditions helps to maintain consistent engine performance 3.

Key Features of the Cummins Fuel Bypass Tube (Part #3053751)

The Cummins Fuel Bypass Tube is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to the harsh conditions found in heavy-duty truck environments. The tube’s build quality includes precise engineering to ensure a secure fit within the fuel system, and it features smooth internal passages to minimize fuel flow resistance. These characteristics enhance the tube’s performance and longevity.

Benefits of Using the Cummins Fuel Bypass Tube

The Cummins Fuel Bypass Tube offers several advantages, including improved fuel efficiency due to its ability to maintain optimal fuel pressure. It also enhances system reliability by preventing fuel-related issues that could lead to engine performance problems. Additionally, the use of this tube can result in potential cost savings for fleet operators by reducing the likelihood of fuel system failures and the associated repair costs.

Installation and Integration

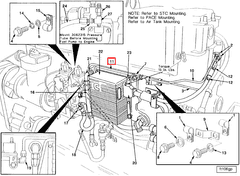

Proper installation of the Cummins Fuel Bypass Tube within a truck’s fuel system is important for ensuring its effectiveness. It is compatible with a range of Cummins engines and fuel system configurations. When integrating the tube, it is important to follow manufacturer guidelines to ensure compatibility with other components and to take necessary precautions to prevent fuel leaks or improper fitting, which could affect system performance.

Troubleshooting Common Issues

Common problems associated with Fuel Bypass Tubes can include fuel leaks, blockages, or improper fitting. These issues may be caused by wear and tear, manufacturing defects, or incorrect installation. Recommended troubleshooting steps include inspecting the tube for signs of damage, ensuring all connections are secure, and checking for proper fuel flow. Addressing these issues promptly can help maintain the efficiency and reliability of the fuel system.

Maintenance and Care

To ensure the long-term performance and reliability of the Cummins Fuel Bypass Tube, regular maintenance and care are recommended. This includes periodic inspection for signs of wear or damage, cleaning the tube to remove any contaminants that could affect fuel flow, and ensuring all connections remain tight. Adhering to these best practices can help extend the lifespan of the tube and maintain optimal fuel system performance.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance engines and components, Cummins has built a reputation for excellence. The company’s product range includes a variety of engine and powertrain solutions designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to advancing technology and improving efficiency is evident in its continued investment in research and development.

Cummins Fuel Bypass Tube 3053751 in Engine Applications

The Cummins Fuel Bypass Tube, part number 3053751, is a critical component in the fuel system of various Cummins engines. This part is designed to manage the flow of fuel within the engine’s fuel system, ensuring efficient operation and performance.

N14 Mechanical Engine

In the N14 Mechanical engine, the Fuel Bypass Tube 3053751 plays a vital role in the fuel management system. It is responsible for directing excess fuel away from the fuel injectors back to the fuel tank, preventing fuel starvation and ensuring a consistent fuel supply. This tube is integral to maintaining the engine’s performance and reliability, especially under varying load conditions.

The installation of the Fuel Bypass Tube in the N14 Mechanical engine involves precise alignment and secure attachment to the fuel injectors and fuel tank. Proper installation is crucial to avoid fuel leaks and ensure the engine operates smoothly. Technicians must follow the manufacturer’s guidelines to ensure the tube is correctly positioned and sealed, maintaining the integrity of the fuel system.

Role of Part 3053751 Fuel Bypass Tube in Engine Systems

The Part 3053751 Fuel Bypass Tube is an integral component within the fuel delivery system of various engine setups. Its primary function is to provide an alternative route for fuel to travel when the main fuel passage is obstructed or when there is a need to regulate fuel pressure. This ensures consistent fuel delivery to the engine, maintaining optimal performance and efficiency.

In the context of the Fuel Bypass Mounting Tube, the Part 3053751 is designed to interface seamlessly, allowing for the secure attachment of the bypass system to the engine’s fuel rail or manifold. This mounting tube facilitates the redirection of fuel flow, preventing any potential buildup of pressure that could lead to fuel system malfunctions.

When considering the Fuel Tubing, the bypass tube works in conjunction to maintain a balanced fuel supply. The tubing connects various components of the fuel system, including the fuel pump, injectors, and the bypass tube itself. The bypass tube ensures that if there is a blockage or restriction in the primary fuel line, fuel can still reach the injectors via the alternative route provided by the bypass system. This redundancy is essential for the reliability and safety of the engine operation.

Overall, the integration of the Part 3053751 Fuel Bypass Tube with these components enhances the engine’s fuel management system, ensuring that it operates smoothly under various conditions.

Conclusion

The Cummins Fuel Bypass Tube (Part #3053751) is a vital component in the fuel systems of heavy-duty trucks and engines. Its role in managing fuel flow, maintaining optimal fuel pressure, and ensuring consistent fuel delivery contributes significantly to the performance, reliability, and efficiency of the engine. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the Fuel Bypass Tube, making it a valuable asset in the operation of heavy-duty vehicles.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.