This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043485 Fuel Supply Tube is a critical component in the fuel systems of heavy-duty trucks. It is designed to transport fuel from the tank to the engine, ensuring a consistent supply that meets the engine’s operational demands. This part is essential for maintaining the efficiency and performance of the vehicle’s fuel system.

Purpose and Function

The Fuel Supply Tube facilitates the delivery of fuel from the tank to the engine, providing a dedicated pathway that ensures consistent fuel pressure and flow. This consistent delivery is vital for the engine’s combustion process, directly influencing the truck’s overall performance and efficiency. The tube is engineered to withstand the pressures and temperatures within the fuel system, ensuring reliable operation under various driving conditions 1.

Key Features

The design and construction of the Cummins 3043485 incorporate materials and connection types that enhance its performance and durability. Typically, these tubes are made from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding environments. The connections are designed for a secure fit, minimizing the risk of leaks and ensuring a stable fuel supply. Unique attributes may include reinforced sections to withstand high pressure or specialized coatings to resist chemical degradation 2.

Benefits

Using the Cummins 3043485 offers several advantages. It contributes to improved fuel efficiency by ensuring a consistent and clean fuel supply to the engine. The tube’s reliable performance enhances the overall reliability of the fuel system, reducing the likelihood of unexpected failures. Additionally, its compatibility with Cummins engine systems ensures seamless integration, maintaining the engine’s designed performance levels 3.

Installation and Compatibility

Proper installation of the Fuel Supply Tube is crucial for its effective operation. Guidelines for installation may include specific tools or procedures to ensure a secure and leak-free connection. Compatibility with various Cummins engine models is a key consideration, ensuring that the tube meets the specific requirements of each engine it is designed to serve.

Maintenance and Troubleshooting

Maintaining the Fuel Supply Tube is important for ensuring optimal performance. Regular inspection intervals can help identify potential issues before they become significant problems. Cleaning procedures may be recommended to remove any contaminants that could affect fuel flow. Common issues that may arise include leaks, clogs, or corrosion, each of which can be addressed through proper maintenance practices.

Common Failure Modes

Typical failure modes for the Fuel Supply Tube include leaks, clogs, or corrosion. Symptoms that may indicate a problem with the tube include engine performance issues, such as reduced power or efficiency, or visible signs of fuel leakage. Early detection and replacement of a failing tube can prevent more severe engine damage and ensure continued reliable operation.

Replacement Procedures

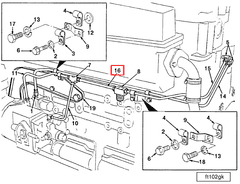

Replacing the Fuel Supply Tube involves several steps to ensure a safe and effective installation. Safety precautions, such as relieving fuel system pressure and disconnecting the battery, should be observed. Necessary tools may include wrenches, fuel line disconnect tools, and possibly a fuel pressure tester. The process involves removing the old tube, inspecting the fuel system for any damage or debris, and installing the new tube with secure connections.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product lines include engines, filtration, emissions solutions, and power generation products, all designed to meet the demanding requirements of various industries.

Cummins Part 3043485: Fuel Supply Tube Compatibility

The Cummins part 3043485, a Fuel Supply Tube, is designed to integrate seamlessly with specific Cummins engine models. This part is crucial for maintaining the integrity of the fuel delivery system, ensuring that fuel is efficiently and accurately supplied to the engine components.

N14 MECHANICAL

For the N14 MECHANICAL engine, the Fuel Supply Tube (part 3043485) plays a pivotal role in the fuel system. It connects various fuel-related components, facilitating the smooth flow of fuel from the fuel tank to the injectors. This tube is engineered to withstand the high pressures and temperatures typical of diesel engines, ensuring durability and reliability.

NH/NT 855

Similarly, in the NH/NT 855 engines, the Fuel Supply Tube (part 3043485) is integral to the fuel supply mechanism. It ensures that fuel is delivered consistently and without leaks, which is vital for the engine’s performance and efficiency. The design of this tube allows it to fit precisely within the engine’s architecture, providing a secure and leak-proof connection.

Grouping of Engines

Both the N14 MECHANICAL and NH/NT 855 engines benefit from the use of the Cummins part 3043485. This part is engineered to fit these engines with precision, ensuring compatibility and optimal performance. The design considerations for this fuel supply tube include the specific dimensions, material strength, and connection points required for each engine model.

Role of Part 3043485 Fuel Supply Tube in Engine Systems

The Part 3043485 Fuel Supply Tube is an essential component in the fuel delivery system of various engine configurations. Its primary function is to transport fuel from the fuel tank to the fuel injectors or carburetor, ensuring a consistent and reliable fuel supply to the engine.

Integration with Fuel Tubing

When integrated with fuel tubing, the Part 3043485 Fuel Supply Tube acts as a robust conduit that withstands the pressure and temperature variations within the fuel system. It connects to the fuel tank at one end and to the fuel filter or directly to the fuel rail at the other, facilitating an uninterrupted flow of fuel. The tube’s design allows for flexibility and durability, accommodating the movements and vibrations inherent in engine operation while maintaining a secure connection.

Role in Plumbing

In the context of engine plumbing, the Part 3043485 Fuel Supply Tube is a vital link in the fuel delivery network. It interfaces with various components such as the fuel pump, fuel filter, and fuel pressure regulator. This integration ensures that fuel is efficiently pumped from the tank, filtered to remove impurities, and regulated to the appropriate pressure before reaching the engine’s combustion chambers. The tube’s precise fit and sealing properties are paramount in preventing fuel leaks and maintaining system integrity.

Contribution to Fuel Supply

As a component of the fuel supply system, the Part 3043485 Fuel Supply Tube plays a significant role in delivering the correct amount of fuel to the engine under varying operating conditions. It works in conjunction with the fuel injectors or carburetor to provide the necessary fuel-air mixture for combustion. The tube’s capacity to handle high-pressure fuel delivery ensures that the engine receives a steady supply of fuel, contributing to optimal performance and efficiency.

Conclusion

The Cummins 3043485 Fuel Supply Tube is a fundamental element in the fuel delivery system, ensuring that fuel is transported efficiently and reliably from the tank to the engine’s combustion points. Its integration with fuel tubing, plumbing components, and the overall fuel supply system underscores its importance in maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.