This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

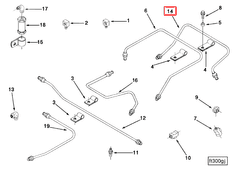

The Cummins 3009872 Fuel Supply Tube is a critical component in the fuel delivery system of commercial trucks. It ensures a consistent and reliable fuel supply to the engine, which is essential for the vehicle’s operation and performance. This part is designed to withstand the pressures and temperatures associated with fuel transport, facilitating a seamless flow of fuel that supports engine efficiency and reliability 1.

Purpose and Function

The primary role of the Fuel Supply Tube is to transport fuel from the storage tank to the engine. This conduit is engineered to maintain a steady fuel flow, which is crucial for combustion and engine operation. The tube’s design ensures it can handle the demands of fuel transport, contributing to the overall performance of the truck’s engine 2.

Key Features

This Cummins part is constructed from durable materials that resist the corrosive effects of fuel. It features reinforced connections to prevent leaks and a smooth interior to minimize flow resistance. These design elements enhance the tube’s longevity and reliability, ensuring it performs well under various operating conditions 3.

Benefits

Using the 3009872 Fuel Supply Tube can improve fuel efficiency due to its design, which minimizes fuel loss and ensures a consistent supply to the engine. It is engineered to perform reliably in harsh conditions typical of commercial trucking environments. Additionally, it is compatible with specific Cummins engine models, ensuring optimal performance when used as intended 4.

Installation and Compatibility

Proper installation of the Fuel Supply Tube is essential for its effective function. It is designed to fit specific engine models, and installation should adhere to manufacturer guidelines to ensure a secure and leak-free connection. Prerequisites for installation may include the correct tools and potentially modifications to the existing fuel system to accommodate the tube.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Supply Tube is recommended to ensure its continued performance. This includes checking for signs of wear or damage and ensuring all connections are secure. Common issues may include leaks or blockages, which can often be resolved by inspecting and cleaning the tube or replacing damaged sections.

Safety Considerations

When handling and working with the Fuel Supply Tube, it is important to observe safety protocols to prevent accidents. This includes working in a well-ventilated area, wearing appropriate personal protective equipment, and ensuring that all fuel system components are properly secured and free from leaks to comply with industry safety standards.

Environmental Impact

The Fuel Supply Tube contributes to reducing emissions and promoting fuel efficiency. By ensuring a consistent and efficient fuel delivery, it helps to optimize engine performance, which can lead to lower fuel consumption and reduced emissions. This aligns with broader efforts to minimize the environmental impact of commercial trucking operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to sustainability, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for commercial vehicles and other applications.

Role of Part 3009872 Fuel Supply Tube in Engine Systems

The 3009872 Fuel Supply Tube is a vital component in the fuel delivery system of various engine setups. It facilitates the transfer of fuel from the fuel tank to the engine’s fuel injection system or carburetor. This seamless flow of fuel is crucial for the consistent operation of the engine.

In fuel-injected engines, the Fuel Supply Tube connects to the fuel pump, which pressurizes the fuel. It then routes the pressurized fuel to the fuel rail, where it is distributed to the individual fuel injectors. Each injector sprays a precise amount of fuel into the combustion chamber, ensuring an optimal air-fuel mixture for efficient combustion.

For engines equipped with carburetors, the Fuel Supply Tube delivers fuel from the tank to the carburetor. Here, the fuel mixes with air before entering the engine’s cylinders. The carburetor regulates the fuel-air mixture based on the engine’s demand, which is influenced by the driver’s throttle input.

The Fuel Supply Tube also interfaces with the fuel filter, which is positioned along the fuel line. The fuel filter removes impurities and contaminants from the fuel, protecting sensitive engine components from damage.

In turbocharged or supercharged engines, the Fuel Supply Tube may be integrated with the boost control system. This ensures that fuel delivery is increased in proportion to the additional air being forced into the engine, maintaining the correct air-fuel ratio under boosted conditions.

Furthermore, the Fuel Supply Tube is often connected to fuel pressure regulators, which monitor and adjust the pressure of the fuel entering the engine. This regulation is essential for maintaining consistent engine performance across varying operating conditions.

Conclusion

In summary, the 3009872 Fuel Supply Tube plays a significant role in ensuring that the engine receives a steady and clean supply of fuel, which is fundamental for the engine’s performance, efficiency, and longevity. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.