This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

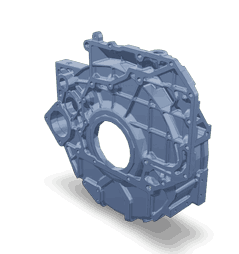

The Flywheel Housing 5255797 is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its robust and reliable engine components. This flywheel housing is designed for use in heavy-duty trucks, where it plays a significant role in ensuring the efficient operation of the engine and transmission system 1.

Basic Concepts of Flywheel Housing

A flywheel housing is an enclosure that houses the flywheel, a heavy rotating disc that stores rotational energy and smooths out the power delivery from the engine to the transmission. It integrates with other engine components such as the crankshaft, clutch, and transmission, ensuring that the rotational energy is effectively transferred and managed 2.

Purpose of Flywheel Housing 5255797

The Flywheel Housing 5255797 is integral to the operation of a truck’s engine and transmission system. It securely holds the flywheel in place, allowing it to interact smoothly with the clutch and transmission. This interaction is vital for the efficient transfer of power from the engine to the drivetrain, ensuring that the truck operates smoothly and reliably under various driving conditions 3.

Key Features

The Flywheel Housing 5255797 is characterized by its robust design and high-quality materials, which contribute to its performance and durability. It is engineered to withstand the high stresses and vibrations associated with heavy-duty truck operations. The housing is typically made from durable cast iron or steel, ensuring it can endure the rigors of heavy-duty use while maintaining precise alignment and fit with other components.

Benefits

The Flywheel Housing 5255797 offers several advantages. It contributes to improved engine stability by securely holding the flywheel in place, which is crucial for smooth engine operation. Additionally, it enhances clutch performance by ensuring a precise fit and alignment, which is essential for efficient power transfer. The durable construction of the housing also increases the longevity of related components, reducing the need for frequent replacements and maintenance.

Installation Process

Installing the Flywheel Housing 5255797 requires careful attention to detail to ensure proper fit and function. The process involves removing the old housing, cleaning the mating surfaces, and aligning the new housing with the engine and transmission components. It is important to use the correct tools and follow manufacturer guidelines to avoid damage to the housing or other components. Proper torque specifications must be adhered to during installation to ensure a secure fit.

Common Issues and Troubleshooting

Typical problems associated with flywheel housings include misalignment, wear, and damage from excessive vibration or stress. Diagnostic methods may involve visual inspection, measurement of component alignment, and assessment of wear patterns. Potential solutions range from realigning components to replacing worn or damaged parts. Regular inspection and maintenance can help identify issues early, preventing more significant problems down the line.

Maintenance Tips

To ensure the longevity and optimal performance of the Flywheel Housing 5255797, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or damage, ensuring proper alignment and fit with other components, and addressing any issues promptly. Additionally, maintaining clean and lubricated moving parts can help reduce wear and extend the life of the housing and related components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to quality and innovation in manufacturing engine components. The company’s extensive experience and dedication to excellence are reflected in its products, including the Flywheel Housing 5255797, which is designed to meet the demanding requirements of heavy-duty truck applications.

Flywheel Housing Compatibility with Cummins Engines

The Flywheel Housing part number 5255797, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral to the engine’s operation, providing a secure housing for the flywheel and contributing to the overall balance and efficiency of the engine.

ISB CM2150 Series

The Flywheel Housing 5255797 is compatible with the ISB CM2150 engine. This engine is known for its robust performance and reliability, making it a popular choice for various applications.

ISB/ISD4.5 CM2150 B119

This specific variant of the ISB/ISD4.5 CM2150 B119 engine also utilizes the Flywheel Housing 5255797. This engine variant is engineered for high-performance applications, ensuring durability and efficiency.

ISB/ISD6.7 CM2150 SN

The ISB/ISD6.7 CM2150 SN engine is another model that fits the Flywheel Housing 5255797. This engine is designed for heavy-duty applications, providing substantial power and reliability.

ISB4.5 CM2350 B104

The ISB4.5 CM2350 B104 engine is compatible with the Flywheel Housing 5255797. This engine variant is tailored for applications requiring a balance of power and efficiency.

ISB6.7 CM2250

The ISB6.7 CM2250 engine is also designed to work with the Flywheel Housing 5255797. This engine is known for its high torque output and reliability, making it suitable for demanding tasks.

ISBE CM2150

The ISBE CM2150 engine fits the Flywheel Housing 5255797. This engine is engineered for applications that require a combination of power and efficiency.

ISBE4 CM850

Lastly, the ISBE4 CM850 engine is compatible with the Flywheel Housing 5255797. This engine is designed for applications that demand a balance of performance and reliability.

Role of Part 5255797 Flywheel Housing in Engine Systems

The part 5255797 Flywheel Housing is an integral component in the assembly and operation of engine systems. It serves as the mounting point for the flywheel, which is a heavy wheel attached to the crankshaft of an engine. The flywheel’s primary function is to store rotational energy and smooth out the power delivery from the engine’s combustion cycles.

When the flywheel is secured to the Flywheel Housing, it allows for the efficient transfer of rotational energy to the transmission system. This transfer is facilitated through the clutch assembly, which is also connected to the flywheel. The Flywheel Housing ensures that the flywheel is properly aligned and supported, which is essential for the smooth operation of the clutch mechanism.

Additionally, the Flywheel Housing plays a role in the engine’s vibration management. By providing a stable and secure mounting point for the flywheel, it helps to minimize the vibrations that are generated during the engine’s operation. This stability is particularly important in high-performance engines where the forces and vibrations are more pronounced.

Furthermore, the Flywheel Housing is often designed to accommodate various engine components such as the starter motor, which engages with the flywheel to start the engine. It also provides a mounting surface for the pressure plate, which is part of the clutch assembly and works in conjunction with the flywheel to engage and disengage the clutch.

In summary, the part 5255797 Flywheel Housing is a key component that ensures the proper functioning of the flywheel, clutch assembly, and starter motor within the engine system. Its design and placement are essential for the efficient transfer of power, management of engine vibrations, and the overall reliability of the engine’s operation.

Conclusion

The Flywheel Housing 5255797 by Cummins is a critical component in the efficient operation of heavy-duty truck engines. Its robust design, compatibility with various Cummins engines, and role in managing rotational energy and vibrations make it an essential part of the engine system. Regular maintenance and proper installation are key to ensuring its longevity and optimal performance.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.