This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

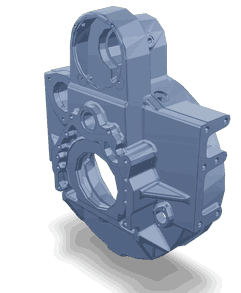

The Cummins 4994473 Flywheel Housing is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by providing a secure enclosure for the flywheel and facilitating the interaction between the engine and transmission systems. This housing is integral to maintaining the structural integrity and operational efficiency of the truck’s engine.

Basic Concepts of Flywheel Housing

A flywheel housing is a part of the engine system that encases the flywheel, which is a heavy rotating disc that stores rotational energy. The housing protects the flywheel and ensures it operates within a controlled environment. It interacts closely with other components such as the clutch, which connects and disconnects the engine from the transmission. The flywheel housing plays a role in maintaining the alignment and stability of these components, ensuring smooth operation and efficient power transfer 1.

Purpose of the 4994473 Flywheel Housing

The 4994473 Flywheel Housing is specifically designed to enhance the operation of trucks by providing a robust and reliable enclosure for the flywheel. It contributes to engine performance by ensuring that the flywheel operates within a stable and protected environment. This housing aids in the durability of the engine by reducing the risk of damage to the flywheel and other connected components. Its design helps in maintaining the balance and efficiency of the engine, which is crucial for the overall performance of the truck 2.

Key Features

The 4994473 Flywheel Housing is constructed from high-quality materials that offer durability and resistance to wear. Its design includes precise engineering to ensure a perfect fit with the engine components. Unique characteristics such as reinforced sections and optimized weight distribution enhance its functionality, providing both strength and efficiency. These features contribute to the overall reliability and performance of the truck’s engine system.

Benefits

The use of the 4994473 Flywheel Housing offers several benefits. It contributes to improved engine efficiency by ensuring that the flywheel operates smoothly and effectively. The durable construction of the housing enhances the longevity of the engine components, reducing the need for frequent replacements. Additionally, the reliable performance of this housing can lead to potential cost savings for fleet operators by minimizing downtime and maintenance costs.

Installation Process

Installing the 4994473 Flywheel Housing involves several steps to ensure proper fit and function. Mechanics should begin by preparing the engine area, ensuring that all necessary tools and components are available. The housing should be aligned with the engine and secured in place according to the manufacturer’s specifications. It is important to check for proper alignment and fit to avoid any issues during operation. Following the installation, a thorough inspection should be conducted to confirm that the housing is correctly installed and that all connections are secure.

Troubleshooting Common Issues

Common issues with the 4994473 Flywheel Housing may include misalignment, wear, or damage. If the housing is misaligned, it can lead to inefficient operation and potential damage to the flywheel or clutch. Wear or damage to the housing may result in leaks or reduced performance. Troubleshooting steps include inspecting the housing for signs of wear or damage, ensuring proper alignment, and making any necessary adjustments or replacements. Regular maintenance and inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4994473 Flywheel Housing, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, damage, or misalignment. Cleaning the housing and surrounding components can help prevent buildup and ensure smooth operation. Following the manufacturer’s recommended service intervals for inspection and maintenance will help maintain the housing’s condition and performance. Additionally, keeping detailed records of maintenance activities can aid in identifying patterns or issues that may require attention.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from light-duty to heavy-duty commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with Cummins Engines

The Flywheel Housing part 4994473, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral to the engine’s operation, providing a secure housing for the flywheel and contributing to the overall balance and efficiency of the engine.

For the ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines, the Flywheel Housing part 4994473 is engineered to match the specific design and requirements of these engines. Its precision fit ensures that the flywheel operates smoothly, reducing wear and enhancing performance.

Similarly, the L8.9 engine also benefits from the Flywheel Housing part 4994473. This part is crafted to align perfectly with the L8.9 engine’s architecture, ensuring optimal functionality and durability.

In summary, the Flywheel Housing part 4994473 is a critical component that fits the ISL9 CM2150 SN, ISL9.5 CM2880 L138, and L8.9 engines, providing a reliable and efficient housing for the flywheel.

Role of Part 4994473 Flywheel Housing in Engine Systems

The 4994473 Flywheel Housing is an integral component in the assembly and operation of engine systems. It serves as the primary mounting point for the flywheel, which is a heavy, rotating disk that stores rotational energy and smooths out the power delivery from the engine’s combustion cycles.

Integration with Key Components

-

Flywheel: The flywheel is securely attached to the Flywheel Housing. This connection ensures that the flywheel can rotate smoothly and efficiently, transferring energy to the transmission system. The housing provides the necessary structural support to withstand the forces generated during engine operation.

-

Clutch Assembly: In manual transmission systems, the Flywheel Housing interfaces with the clutch assembly. The pressure plate, which is part of the clutch, mounts to the Flywheel Housing. This arrangement allows for the engagement and disengagement of the flywheel, facilitating gear changes.

-

Engine Block: The Flywheel Housing is bolted to the rear of the engine block. This connection is vital for maintaining alignment and stability between the engine and the transmission. Proper mounting ensures that the rotational forces are transmitted effectively without causing undue stress on the engine components.

-

Transmission Bell Housing: The Flywheel Housing mates with the transmission bell housing, forming a critical junction between the engine and the transmission. This interface must be precisely aligned to ensure a smooth transfer of power and to prevent leaks at the gasket seal.

-

Starter Motor: The Flywheel Housing often includes provisions for the starter motor. The starter engages with the flywheel to initiate engine cranking. The housing must provide adequate clearance and alignment for the starter motor to function correctly.

-

Flexplate (Automatic Transmissions): In automatic transmission systems, the Flywheel Housing accommodates the flexplate, which serves a similar role to the flywheel in manual transmissions. The flexplate connects to the torque converter, which in turn engages with the transmission.

Functional Dynamics

The Flywheel Housing plays a significant role in the dynamic balance of the engine system. It helps to dampen vibrations caused by the reciprocating motion of the pistons, contributing to a smoother operation. Additionally, it houses various sensors and components that monitor engine performance, such as the crankshaft position sensor, which relies on the flywheel’s teeth for accurate readings.

Conclusion

In summary, the 4994473 Flywheel Housing is a foundational element that ensures the efficient and reliable operation of the engine and transmission system. Its role in mounting, aligning, and supporting other critical components underscores its importance in the overall functionality of the engine.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.