This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

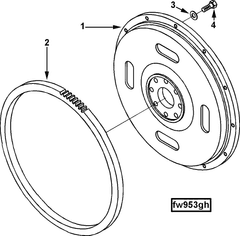

The Cummins 3352875 Flywheel is a vital component in the operation of commercial trucks, designed to enhance engine performance and ensure smooth operation. This part is integral to the engine’s functionality, providing stability and efficiency in power delivery.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and smooths out the power delivery of an engine. It operates on the principle of inertia, maintaining a consistent rotational speed by storing energy during the power stroke and releasing it during the other strokes of the engine cycle. Within an engine system, the flywheel plays a role in stabilizing the engine’s rotational speed, ensuring consistent power delivery and reducing vibrations 1.

Purpose of the Cummins 3352875 Flywheel

The Cummins 3352875 Flywheel is designed to interact with various engine components to optimize performance. It works in conjunction with the crankshaft, clutch, and transmission to provide a smooth transfer of power from the engine to the drivetrain. By storing and releasing energy, the flywheel helps maintain a steady engine speed, which is particularly important in the variable load conditions typical of commercial truck operations 2.

Key Features

This Cummins part is characterized by its robust design and high-quality materials. It is constructed from durable materials to withstand the rigors of heavy-duty use. The flywheel features a balanced design to minimize vibrations and ensure smooth operation. Additionally, it incorporates advanced engineering to enhance performance and longevity.

Benefits

The Cummins 3352875 Flywheel offers several benefits that contribute to improved engine performance. It provides a smoother operation by stabilizing the engine’s rotational speed, which leads to enhanced drivability and reduced wear on other components. The flywheel’s durable construction ensures increased longevity, making it a reliable choice for commercial truck applications.

Installation Process

Proper installation of the Cummins 3352875 Flywheel is crucial for ensuring optimal performance. The process involves several steps:

- Ensure the engine is securely supported and the transmission is disconnected.

- Remove the old flywheel, taking care to note its position and any shims used.

- Clean the mating surfaces to ensure a proper fit.

- Install the new flywheel, ensuring it is aligned correctly with the crankshaft.

- Reinstall the clutch and transmission, following the manufacturer’s guidelines.

- Perform a final inspection to ensure all components are securely in place and properly aligned.

Common Issues and Troubleshooting

Common issues with the Cummins 3352875 Flywheel may include vibrations, difficulty in shifting gears, or unusual noises. These issues can often be traced to improper installation, wear and tear, or misalignment. Troubleshooting steps include:

- Inspecting the flywheel for signs of wear or damage.

- Ensuring proper alignment and secure installation.

- Checking for any loose or damaged components in the clutch and transmission system.

Maintenance Tips

To ensure the Cummins 3352875 Flywheel operates at peak performance, regular maintenance is recommended. This includes:

- Periodically inspecting the flywheel for signs of wear or damage.

- Ensuring the clutch and transmission are properly aligned and functioning correctly.

- Following the manufacturer’s guidelines for service intervals and replacement parts.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 3352875 Flywheel, which is designed to meet the demanding requirements of heavy-duty applications.

Cummins Flywheel Part 3352875 Compatibility

The Cummins flywheel part number 3352875 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This flywheel is engineered to work with the following Cummins engines:

6B5.9 Engine

The 6B5.9 engine benefits from the robust design of the 3352875 flywheel, which is crucial for maintaining the engine’s smooth operation. The flywheel’s precision engineering ensures that it can handle the specific demands of the 6B5.9 engine, contributing to its overall efficiency and longevity.

6C8.3 Engine

Similarly, the 6C8.3 engine is another model that is compatible with the 3352875 flywheel. This engine, known for its power and reliability, pairs well with the flywheel’s design, which is tailored to meet the rigorous requirements of the 6C8.3 engine’s performance characteristics.

Grouping of Engines

Both the 6B5.9 and 6C8.3 engines share common traits that make them suitable for the 3352875 flywheel. These engines are part of a series that demands high-quality components to ensure peak performance. The flywheel’s design is optimized to work with these engines, providing a reliable connection between the engine and the transmission, which is vital for smooth operation and durability.

Role of Part 3352875 Flywheel in Engine Systems

The flywheel, specifically part 3352875, is integral to the operation of engine systems, serving as a pivotal component in the powertrain. Its primary function is to store rotational energy and smooth out the power delivery from the engine’s combustion cycles.

When the engine’s pistons move, they create a rotational force that is transferred to the crankshaft. The flywheel is connected to the crankshaft and, due to its mass and inertia, it resists changes in rotational speed. This resistance helps to maintain a consistent rotational speed, which is essential for the smooth operation of the engine.

The flywheel also plays a significant role in the operation of the clutch system. In manual transmission vehicles, the flywheel is part of the clutch assembly. When the clutch pedal is depressed, the pressure plate is moved away from the flywheel, disconnecting the engine from the transmission. This allows the driver to change gears without interrupting the engine’s operation. When the clutch pedal is released, the pressure plate pushes the clutch disc against the flywheel, re-engaging the engine with the transmission.

In addition to its role in the clutch system, the flywheel is also involved in the starting process of the engine. The starter motor engages with the flywheel to crank the engine, initiating the combustion process. Once the engine starts, the flywheel continues to store and release energy, contributing to the engine’s overall efficiency and performance.

Furthermore, the flywheel’s design and material properties are tailored to withstand the high stresses and temperatures generated during engine operation. This ensures durability and reliability, making it a key component in the engine’s powertrain system 3.

Conclusion

The Cummins 3352875 Flywheel is a critical component in the operation of commercial trucks, designed to enhance engine performance and ensure smooth operation. Its robust design, durable materials, and advanced engineering contribute to its reliability and longevity. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this part.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.