This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

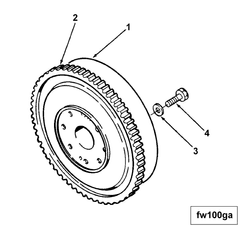

The Cummins 3031944 Flywheel is a critical component in the operation of commercial trucks. It enhances engine performance and efficiency by managing rotational energy and ensuring smooth engine operation. Understanding its role and significance is essential for maintaining optimal truck performance.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy when the engine accelerates and releasing it when the engine decelerates. This function is vital for stabilizing engine operation, particularly in the varying load conditions typical of commercial trucks 1.

Purpose of the Cummins 3031944 Flywheel

The Cummins 3031944 Flywheel plays a significant role in the operation of a truck by storing rotational energy and smoothing engine operation. It helps balance the power delivery from the engine to the transmission, ensuring that the truck operates efficiently under different load conditions. By storing energy during the power stroke and releasing it during the other strokes, the flywheel contributes to a more consistent and stable engine performance 2.

Key Features

The Cummins 3031944 Flywheel is characterized by several key features that enhance its performance. Its design incorporates a robust construction that can withstand the high stresses and torques encountered in heavy-duty applications. The flywheel is made from high-quality materials, ensuring durability and reliability. Additionally, it features precision machining and balancing to minimize vibrations and ensure smooth operation 3.

Benefits

The Cummins 3031944 Flywheel offers several advantages. It contributes to improved engine efficiency by ensuring a consistent rotational speed, which can lead to better fuel economy. The durable construction and high-quality materials used in its manufacture enhance its longevity and reliability, making it suitable for heavy-duty conditions. Furthermore, the flywheel’s design helps to reduce engine vibrations, leading to a smoother and more comfortable driving experience 4.

Installation Considerations

Proper installation of the Cummins 3031944 Flywheel is crucial for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines for torque specifications and alignment to prevent issues such as misalignment or improper seating. Ensuring that all mating surfaces are clean and free of debris will also contribute to a secure and efficient installation.

Troubleshooting Common Issues

Flywheels can encounter several common issues, such as excessive wear, noise, or vibration. Excessive wear may indicate improper installation or abnormal operating conditions, while noise could suggest a problem with the clutch or other components. Vibrations may point to imbalance or misalignment. Troubleshooting these issues involves inspecting the flywheel and related components, ensuring proper installation, and addressing any underlying problems promptly.

Maintenance Tips

Routine maintenance is key to prolonging the life of the Cummins 3031944 Flywheel. Regular inspections should be conducted to check for signs of wear or damage. Cleaning the flywheel and its mating surfaces can prevent the buildup of debris that may cause issues. Additionally, ensuring that the clutch system is in good condition will contribute to the overall performance and longevity of the flywheel.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the manufacturing of engines and components for various applications, including commercial trucks.

Role of Part 3031944 Flywheel in Engine Systems

The flywheel, identified by part number 3031944, is an integral component within the engine system, facilitating smooth operation and efficient energy transfer. Its primary function is to store rotational energy and deliver it to other parts of the engine as needed.

When the engine’s pistons move, they create rotational force that is transferred to the crankshaft. The flywheel is connected to the crankshaft and helps to stabilize this rotational motion. By doing so, it minimizes vibrations and ensures a consistent power delivery to the transmission system.

Additionally, the flywheel plays a significant role in the starting process of the engine. It engages with the starter motor through the starter ring gear, allowing the engine to crank and start. Once the engine is running, the flywheel continues to smooth out the power pulses from the combustion process, providing a steady rotational force to the transmission.

In manual transmission systems, the flywheel also interacts with the clutch. When the clutch pedal is pressed, the clutch disengages from the flywheel, allowing the driver to shift gears without interrupting the engine’s operation. Upon releasing the clutch pedal, the clutch re-engages with the flywheel, transferring power from the engine to the transmission and ultimately to the wheels.

Overall, the flywheel (part 3031944) is essential for maintaining engine stability, facilitating smooth gear changes, and ensuring efficient energy transfer throughout the engine system.

Conclusion

The Cummins 3031944 Flywheel is a vital component in the operation of commercial trucks, contributing to engine stability, efficient energy transfer, and smooth gear changes. Understanding its role, features, and benefits can help in maintaining optimal truck performance and prolonging the life of this critical part.

-

Pacejka, Hans B. Tyre and Vehicle Dynamics. Butterworth-Heinemann, 2006.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.