This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

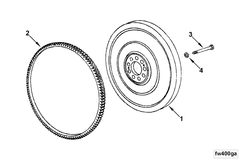

The Cummins 3027737 Flywheel is a component designed for use in commercial trucks, playing a significant role in the engine’s operation. This part is engineered to enhance the performance and reliability of the truck’s engine system, ensuring smooth and efficient operation under various driving conditions.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps maintain a consistent rotational speed within an engine system. It operates on the principle of inertia, resisting changes in rotational speed by storing energy during acceleration and releasing it during deceleration. Within an engine, the flywheel smooths out the power delivery from the combustion cycles, contributing to a more stable and efficient operation 1.

Purpose of the Cummins 3027737 Flywheel

The Cummins 3027737 Flywheel serves multiple functions in the operation of a truck. Primarily, it stores rotational energy, which helps in smoothing the engine’s operation by balancing the power pulses from the combustion cycles. This results in a more consistent power delivery to the transmission, enhancing the driving experience and reducing wear on the engine components. Additionally, the flywheel plays a role in the engagement of the clutch, facilitating smooth gear changes 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, ensuring durability and performance. Its construction includes precision-balanced components to minimize vibrations and ensure smooth operation. The flywheel is also designed to withstand the high torque and stress levels typical in commercial truck applications, contributing to its longevity and reliability.

Benefits of Using the Cummins 3027737 Flywheel

Incorporating the Cummins 3027737 Flywheel into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring smooth power delivery and reducing the strain on the engine components. The flywheel’s durable construction and resistance to wear also lead to enhanced longevity, potentially reducing maintenance costs for fleet operators. Furthermore, its efficient design can contribute to better fuel economy, offering additional cost savings over time 3.

Installation Considerations

Proper installation of the Cummins 3027737 Flywheel is crucial for ensuring optimal performance and longevity. It is recommended to follow the manufacturer’s guidelines for installation, which may include specific torque settings for bolts and the use of alignment tools to ensure the flywheel is correctly positioned. Attention to detail during installation can prevent issues such as misalignment or improper seating, which could lead to performance issues or damage.

Troubleshooting Common Issues

Flywheels, including the Cummins 3027737, can encounter issues such as wear, cracking, or imbalance. Common symptoms of flywheel problems include difficulty in shifting gears, unusual noises from the engine area, or vibrations felt through the vehicle. Troubleshooting steps may involve inspecting the flywheel for signs of wear or damage, checking the alignment and seating, and ensuring the clutch system is functioning correctly. Addressing these issues promptly can prevent further damage and ensure the continued smooth operation of the engine.

Maintenance Tips

To ensure the Cummins 3027737 Flywheel operates at its best, regular maintenance is recommended. This includes inspecting the flywheel for signs of wear or damage during routine engine maintenance checks. Keeping the flywheel clean and free from contaminants can also contribute to its longevity. Additionally, ensuring the clutch system is in good condition and operates smoothly can help maintain the flywheel’s performance. Following the manufacturer’s maintenance schedule and guidelines can help maximize the lifespan and efficiency of the flywheel.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product line and support services make it a preferred choice for fleet operators and manufacturers worldwide.

Cummins Flywheel Part 3027737 Compatibility

The Cummins flywheel part number 3027737 is designed to be compatible with a range of engine models. This flywheel is engineered to work seamlessly with the following engines:

- QSK19 CM2350

- QSK19 CM500

- QSK19 CM850 MCRS

These engines are part of Cummins’ QSK19 series, which is known for its robust performance and reliability in various industrial applications. The flywheel part 3027737 is specifically tailored to meet the demands of these engines, ensuring smooth operation and efficient power transfer.

For the K19 and K114 engines, while not explicitly listed, the part 3027737 may also be compatible based on similar design specifications and performance requirements. It is always recommended to verify compatibility with the specific engine model and consult the manufacturer’s guidelines or a certified technician to ensure proper fitment and functionality.

Role of Part 3027737 Flywheel in Engine Systems

The flywheel, identified by part number 3027737, is an integral component in the operation of an engine system. It is primarily responsible for storing rotational energy and ensuring smooth power delivery between the engine’s power strokes.

When the engine’s pistons move, they create an inconsistent rotational force. The flywheel counteracts this by using its mass to smooth out the power delivery, thus maintaining a consistent rotational speed. This is particularly important in internal combustion engines where the power delivery is not uniform.

The flywheel is connected to the crankshaft via the clutch assembly. During operation, the flywheel rotates with the crankshaft, storing kinetic energy during the power strokes and releasing it during the other phases of the engine cycle—intake, compression, and exhaust. This stored energy helps to keep the engine running smoothly, even when the power output is momentarily reduced.

Additionally, the flywheel plays a significant role in the starting process of the engine. When the starter motor engages, it spins the flywheel, which in turn rotates the crankshaft, initiating the engine cycle.

In manual transmission vehicles, the flywheel also serves as the friction surface for the clutch. When the clutch pedal is pressed, the pressure plate disengages from the flywheel, allowing the driver to shift gears without interrupting the engine’s rotation. Once the pedal is released, the pressure plate re-engages with the flywheel, transferring power from the engine to the transmission.

In summary, the flywheel (part 3027737) is essential for maintaining engine smoothness, aiding in the starting process, and facilitating gear changes in manual transmissions. Its design and mass are tailored to the specific requirements of the engine it serves, ensuring optimal performance and durability.

Conclusion

The Cummins 3027737 Flywheel is a critical component in the operation of commercial truck engines, offering benefits such as improved engine efficiency, enhanced longevity, and better fuel economy. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for ensuring the optimal performance and durability of this part. With its robust design and compatibility with a range of Cummins engines, the 3027737 Flywheel is a reliable choice for fleet operators and manufacturers seeking to enhance the performance and reliability of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.