This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

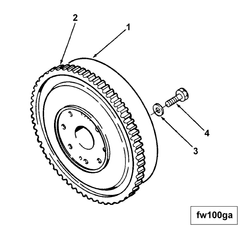

The Cummins 3008174 Flywheel is a component designed to enhance the operation of commercial trucks. Its role is significant in ensuring the smooth and efficient functioning of the engine. This flywheel is engineered to store rotational energy and contribute to the overall performance of the truck’s engine system.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to smooth out the operation of an engine. It works on the principle of inertia, maintaining a consistent rotational speed by resisting changes in velocity. Within an engine system, the flywheel plays a role in stabilizing the engine’s rotation, particularly during the power strokes and compression phases of the combustion cycle 1. This stabilization is crucial for maintaining a steady engine operation and ensuring efficient energy transfer.

Purpose of the 3008174 Flywheel

The Cummins 3008174 Flywheel is specifically designed to enhance the operation of commercial trucks. It contributes to engine performance by storing and transferring energy during the combustion process. This flywheel helps to maintain a consistent rotational speed, which is vital for the efficient operation of the engine. By smoothing out the power delivery, it plays a role in reducing vibrations and ensuring a stable engine performance under various driving conditions.

Key Features

The Cummins 3008174 Flywheel is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions of commercial truck operations. The flywheel’s design includes features that enhance its performance and durability, such as a balanced weight distribution and precise machining. These characteristics ensure that the flywheel can effectively store and transfer energy, contributing to the overall efficiency of the engine 2.

Benefits

Using the Cummins 3008174 Flywheel offers several benefits. It contributes to improved engine efficiency by ensuring smooth energy transfer during the combustion process. The flywheel’s durable construction enhances its reliability under heavy-duty conditions, providing consistent performance over time. Additionally, its design helps to reduce engine vibrations, leading to a more stable and efficient operation 3.

Installation Considerations

Proper installation of the Cummins 3008174 Flywheel is important for ensuring optimal performance. It is designed to be compatible with various truck models and engine types. When installing this flywheel, it is important to follow the manufacturer’s guidelines to ensure it is properly aligned and secured. This includes checking for any necessary adjustments or additional components that may be required for a specific truck model.

Maintenance and Troubleshooting

To ensure the Cummins 3008174 Flywheel operates at its best, regular maintenance is recommended. This includes inspecting the flywheel for any signs of wear or damage and ensuring it remains properly aligned. Common issues that may arise include uneven wear or vibrations, which can often be addressed by checking the alignment and condition of the flywheel. Regular maintenance helps to prolong the lifespan of the component and ensures consistent engine performance.

Performance Enhancements

The Cummins 3008174 Flywheel can contribute to overall truck performance in several ways. By ensuring smooth energy transfer, it plays a role in enhancing fuel efficiency and power output. Its robust design and reliable performance under heavy-duty conditions help to maintain the truck’s reliability and efficiency over time. This flywheel is an integral part of the engine system, contributing to the truck’s overall performance and durability.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company has a long history of producing reliable and high-performance automotive components. Cummins’ reputation is built on its dedication to engineering excellence and its focus on meeting the demanding needs of commercial truck operators. The Cummins 3008174 Flywheel is a testament to this commitment, offering durable and efficient performance for commercial trucks.

Cummins Flywheel Part 3008174 Compatibility

The Cummins flywheel part number 3008174 is designed to integrate seamlessly with specific engine models, ensuring optimal performance and reliability. This flywheel is engineered to fit the N14 MECHANICAL and NH/NT 855 engines, which are part of Cummins’ robust lineup of industrial and heavy-duty engines.

For the N14 MECHANICAL engine, the flywheel plays a crucial role in the engine’s operation by storing rotational energy and helping to maintain a consistent engine speed. The design of the 3008174 flywheel is tailored to match the unique specifications of the N14 MECHANICAL, ensuring a precise fit and efficient energy transfer.

Similarly, the NH/NT 855 engine benefits from the 3008174 flywheel, which is engineered to handle the specific demands of this engine model. The flywheel’s design allows it to effectively manage the rotational forces and contribute to the smooth operation of the NH/NT 855 engine.

Both engines rely on the flywheel to provide a stable platform for the engine’s crankshaft, ensuring that the engine runs smoothly and efficiently. The 3008174 flywheel is crafted to meet the rigorous standards set by Cummins, guaranteeing durability and performance in demanding applications.

Role of Part 3008174 Flywheel in Engine Systems

The flywheel, identified by part number 3008174, is an integral component in the operation of an engine system. Its primary function is to store rotational energy and smooth out the power delivery from the engine’s combustion cycles. This ensures consistent engine operation and aids in the efficient transfer of power to the transmission system.

Interaction with the Crankshaft

The flywheel is bolted to the rear of the crankshaft. As the crankshaft rotates, driven by the engine’s combustion events, the flywheel stores kinetic energy. This stored energy helps maintain the engine’s momentum between power strokes, ensuring a steady rotational speed 4.

Clutch Engagement

In manual transmission vehicles, the flywheel plays a key role in the clutch system. When the clutch pedal is depressed, the pressure plate is disengaged from the flywheel, allowing the driver to change gears without interrupting the engine’s rotation. Upon releasing the clutch pedal, the pressure plate re-engages with the flywheel, transferring engine power to the transmission.

Starter Motor Interaction

During engine start-up, the flywheel engages with the starter motor’s pinion gear. The starter motor rotates the flywheel, which in turn cranks the engine, initiating the combustion process. The flywheel’s inertia helps the engine reach the necessary speed for self-sustained operation.

Vibration Dampening

The flywheel also acts as a vibration dampener. Its mass absorbs and smooths out the pulsations caused by the engine’s combustion cycles. This results in a more stable and comfortable driving experience, reducing wear on other engine components.

Balance Shaft Synchronization

In engines equipped with balance shafts, the flywheel aids in synchronizing their rotation. Balance shafts are designed to counteract the vibrations produced by the engine’s moving parts. The flywheel’s consistent rotation helps maintain the precise timing required for effective vibration cancellation.

Torque Converter Engagement (Automatic Transmissions)

In vehicles with automatic transmissions, the flywheel’s counterpart is the flexplate. The torque converter, which replaces the clutch in automatic transmissions, engages with the flexplate. The flywheel’s role in manual transmissions is analogous to the flexplate’s role in automatics, ensuring smooth power transfer and engine operation.

Conclusion

In summary, the Cummins 3008174 Flywheel is a multifaceted component that ensures the engine operates smoothly, efficiently transfers power, and maintains consistent rotational speed, contributing to the overall performance and durability of the engine system.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩ -

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Charging the Internal Combustion Engine, Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.