This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

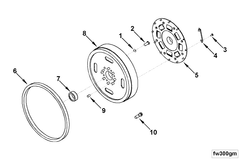

The Cummins 3004152 Flywheel is a component designed for use in heavy-duty trucks. It plays a significant role in the operation of these vehicles by contributing to engine performance, fuel efficiency, and overall drivetrain functionality. Understanding its purpose and significance can provide valuable insights into the mechanics of heavy-duty truck engines.

Basic Concepts of a Flywheel

A flywheel is a mechanical device that stores rotational energy and helps to smooth out engine operation. It consists of a heavy wheel attached to the crankshaft, which rotates at high speeds. The flywheel’s primary function is to maintain a consistent rotational speed by storing energy during the power stroke and releasing it during the other strokes of the engine cycle. This process helps to stabilize the engine’s operation and reduce vibrations 1.

Purpose of the 3004152 Flywheel

The Cummins 3004152 Flywheel is specifically designed to enhance the performance of heavy-duty trucks. It plays a role in the engine system by storing rotational energy, which helps to maintain a smooth and consistent engine operation. This flywheel contributes to improved engine performance, better fuel efficiency, and enhanced drivetrain functionality. By ensuring a stable rotational speed, it aids in the efficient transfer of power from the engine to the transmission, ultimately leading to a more reliable and responsive driving experience.

Key Features

The Cummins 3004152 Flywheel is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials, such as durable alloys, to withstand the rigors of heavy-duty use. The flywheel is engineered to provide optimal balance and precision, ensuring smooth operation and minimal wear. Additionally, it features a robust construction that can handle the high torque and stress associated with heavy-duty applications.

Benefits

Using the Cummins 3004152 Flywheel in heavy-duty trucks offers several benefits. It contributes to improved engine efficiency by ensuring a stable rotational speed, which leads to more consistent power delivery. The flywheel’s durable construction enhances the overall reliability and longevity of the engine. Furthermore, it plays a role in reducing engine vibrations and providing a smoother driving experience, which can be particularly beneficial in demanding applications.

Installation Considerations

Proper installation of the Cummins 3004152 Flywheel is crucial for ensuring optimal performance and compatibility with various truck models and engine types. It is important to follow manufacturer guidelines and ensure that all components are correctly aligned and secured. Compatibility with specific truck models and engine configurations should be verified to ensure a proper fit and function.

Maintenance and Troubleshooting

Maintaining the Cummins 3004152 Flywheel is essential for ensuring its optimal performance and longevity. Regular inspections for signs of wear or damage are recommended. Common issues may include uneven wear, cracks, or imbalance, which can affect engine performance. Troubleshooting tips include checking for proper alignment, ensuring secure mounting, and addressing any unusual vibrations or noises. Recommended maintenance practices involve periodic cleaning and lubrication of moving parts to prevent excessive wear 2.

Performance Enhancements

The Cummins 3004152 Flywheel can contribute to performance enhancements in heavy-duty trucks. By providing a stable rotational speed and efficient energy transfer, it helps to improve torque delivery and acceleration. This results in a more responsive and powerful driving experience, making it well-suited for demanding applications where reliable performance is crucial.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry, particularly for producing high-quality diesel engines and components. Founded in 1919, Cummins has established itself as a leader in engine technology, offering a wide range of products designed for various applications, including heavy-duty trucks. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry 3.

Role of Part 3004152 Flywheel in Engine Systems

The 3004152 Flywheel is integral to the smooth operation of various engine systems. It works in conjunction with several key components to ensure efficient energy transfer and engine performance.

Interaction with the Clutch System

When the clutch is engaged, the flywheel is directly connected to the engine’s crankshaft. As the engine generates power, the flywheel stores this energy in the form of rotational inertia. This stored energy is then transferred to the transmission system, allowing for seamless gear changes and consistent power delivery to the drivetrain.

Contribution to the Starter Motor

During engine start-up, the flywheel plays a vital role in engaging with the starter motor. The starter motor’s pinion gear meshes with the flywheel’s ring gear, initiating the engine’s rotation. This interaction is essential for the engine to reach the necessary RPM for combustion to begin.

Influence on the Drivetrain

Once the engine is running, the flywheel continues to interact with the drivetrain components. Its mass and design help in smoothing out the power delivery from the engine to the transmission. This results in reduced vibrations and a more stable driving experience.

Relationship with the Vibration Damper

The flywheel often incorporates a vibration damper, which helps in reducing the torsional vibrations that occur due to the reciprocating motion of the engine’s pistons. This damper ensures that the power transmitted to the transmission is consistent, enhancing overall engine performance and longevity.

Impact on the Flywheel Housing

The flywheel is housed within the flywheel housing, which is part of the engine block. This housing must be precisely machined to ensure a perfect fit and alignment with the flywheel. Proper alignment is essential for the efficient transfer of power and the reduction of wear on associated components.

Connection to the Pressure Plate

In manual transmission systems, the flywheel is directly connected to the pressure plate. The pressure plate, in turn, is linked to the clutch disc. This assembly allows for the engagement and disengagement of the clutch, facilitating gear changes and controlling the flow of power from the engine to the transmission.

Effect on the Dual-Mass Flywheel (if applicable)

In systems equipped with a dual-mass flywheel, the 3004152 Flywheel contributes to enhanced comfort and reduced NVH (Noise, Vibration, and Harshness). The dual-mass design incorporates a secondary mass that further isolates the engine’s vibrations, providing a smoother driving experience.

Conclusion

In summary, the 3004152 Flywheel is a fundamental component that interacts with various engine systems to ensure efficient operation, smooth power delivery, and reduced vibrations. Its role extends beyond simple energy storage, influencing multiple aspects of engine performance and drivetrain functionality.

-

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.