This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

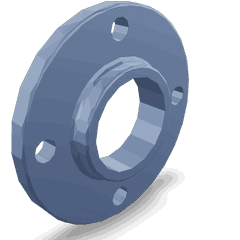

The Cummins 4020126 Flange is a component designed for use in commercial truck operations. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Flanges

A flange is a type of fitting used in mechanical systems to connect different components, such as pipes, valves, and other equipment. It typically consists of a flat, circular plate with holes for bolts, allowing for secure attachment. Flanges facilitate the connection and disconnection of components, enabling maintenance and repairs without requiring extensive disassembly 1.

Purpose of the 4020126 Flange in Truck Operations

This part plays a role in the operation of a commercial truck by providing a secure connection point within the truck’s system. It is designed to interface with specific components, ensuring a reliable and leak-free connection. This flange is integral to maintaining the integrity of the system it is part of, contributing to the truck’s overall performance and durability.

Key Features of the 4020126 Flange

The design and construction of the 4020126 Flange include several features that make it suitable for its intended use. These features may include the material composition, which is chosen for its strength and resistance to corrosion, the size, which is tailored to fit specific applications, and the connection type, which ensures a secure and stable attachment. These characteristics contribute to the flange’s effectiveness in commercial truck operations 2.

Benefits of Using the 4020126 Flange

The 4020126 Flange offers several advantages when used in truck systems. Its durable construction ensures long-term reliability, while its design facilitates ease of installation. Additionally, the flange may provide performance enhancements, such as improved sealing capabilities or reduced vibration, contributing to the efficient operation of the truck’s system.

Installation and Integration

Proper installation of the 4020126 Flange is important to ensure it functions correctly within the truck’s system. Installation procedures should follow manufacturer guidelines to achieve optimal performance. This includes ensuring the flange is correctly aligned, securely fastened, and properly sealed to prevent leaks and maintain system integrity.

Maintenance and Troubleshooting

Regular maintenance practices can help ensure the longevity and efficient operation of the 4020126 Flange. This may include periodic inspections for signs of wear or damage, cleaning to remove any debris that could affect performance, and tightening connections as needed. Troubleshooting tips can help identify and address issues such as leaks or loose connections, ensuring the flange continues to function effectively 3.

Common Issues and Solutions

Common problems that may arise with the 4020126 Flange include leaks, corrosion, and loose connections. Solutions to these issues may involve tightening connections, applying sealant, or replacing damaged components. Addressing these problems promptly can help maintain the flange’s performance and prevent more significant issues from developing.

About Cummins

Cummins Inc. is a company with a history of providing diesel engines and related components. Known for its expertise and reputation in the industry, Cummins offers a range of products designed to meet the demands of commercial truck operations. The company’s commitment to quality and innovation ensures that its components, including the 4020126 Flange, are reliable and effective solutions for truck systems.

Cummins Engine Flange 4020126 Compatibility

The Cummins flange part number 4020126 is designed to fit seamlessly with a range of Cummins engines, ensuring robust connections and reliable performance. This flange is engineered to meet the stringent standards required for heavy-duty applications, providing a critical component in the engine assembly.

K38 and K50 Engines

The flange 4020126 is compatible with the K38 and K50 engines, which are known for their durability and efficiency in various industrial applications. These engines benefit from the flange’s precision fit, which ensures a secure seal and minimizes the risk of leaks, contributing to the overall reliability of the engine system.

QSK50 CM2150 and QSK50 CM2150 MCRS Engines

For the QSK50 CM2150 and QSK50 CM2150 MCRS engines, the flange 4020126 is an essential component that facilitates the connection between different parts of the engine. The flange’s design allows for easy installation and removal, making maintenance and repairs more efficient. Its compatibility with these engines ensures that the flange can handle the high pressures and temperatures typical of these models.

QSK60 CM850 MCRS Engine

The flange 4020126 is also suitable for the QSK60 CM850 MCRS engine, providing a critical connection point that supports the engine’s performance. This engine, like the others, relies on the flange’s precision and durability to maintain its operational integrity. The flange’s fit ensures that the engine components are securely attached, reducing the likelihood of mechanical failures.

Grouping of Engines

The flange 4020126 is designed to be versatile, fitting a range of Cummins engines from the K series to the QSK series. This versatility is particularly beneficial for fleets and operators who use multiple engine models, as it simplifies inventory management and maintenance procedures. The flange’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, interchangeable parts that enhance engine performance and longevity.

Role of Part 4020126 Flange in Engine Systems

This part is an essential component in the integration and operation of various engine systems, particularly those involving fluid dynamics and cooling mechanisms. Its primary function is to facilitate secure and efficient connections between different components, ensuring the smooth transfer of fluids and maintaining system integrity.

Connection to Raw Water Inlet

The flange plays a significant role in the connection to the raw water inlet. This connection is vital for drawing in external water, typically from a seawater source, into the engine’s cooling system. The flange ensures a leak-proof seal, preventing any water loss and maintaining the efficiency of the cooling process.

Integration with Pump Systems

In pump systems, the flange is used to connect the pump to other components, such as pipes or additional pumps. This connection is essential for the consistent flow of raw water through the system. The flange’s design allows for easy installation and removal, facilitating maintenance and repairs without disrupting the entire system.

Seawater Circulation

For engines that utilize seawater for cooling, the flange is instrumental in circulating seawater through the system. It connects the seawater intake to the engine’s cooling passages, ensuring that the water flows efficiently to dissipate heat. This connection is particularly important in marine engines, where seawater is the primary cooling medium.

Raw Water System Efficiency

In raw water systems, the flange ensures that the water flows smoothly from the intake to the engine components that require cooling. This efficient flow is essential for maintaining optimal engine temperature and preventing overheating, which can lead to engine damage.

Overall System Reliability

By providing secure and efficient connections, the flange contributes to the overall reliability of the engine system. It helps in maintaining consistent fluid flow, preventing leaks, and ensuring that all components work together seamlessly. This reliability is particularly important in high-stress environments, such as marine applications, where engine performance is crucial for safety and efficiency.

Conclusion

The Cummins 4020126 Flange is a critical component in commercial truck operations, offering durable construction, ease of installation, and performance enhancements. Its compatibility with a range of Cummins engines ensures versatility and simplifies maintenance procedures. Proper installation, regular maintenance, and prompt troubleshooting are essential for maintaining the flange’s performance and ensuring the reliability of the truck’s system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.