4984462

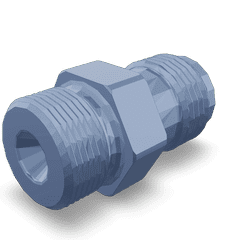

High Pressure Fuel Fitting

Cummins®

IN STOCK

7 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The High Pressure Fuel Fitting 4984462, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation in diesel engine technology. This part is integral to the efficient operation of truck fuel systems, ensuring reliable performance and efficiency in diesel engines.

Basic Concepts of High Pressure Fuel Fittings

High pressure fuel fittings are components used in diesel engines to connect various parts of the fuel system, including fuel injectors, fuel rails, and fuel lines. These fittings are designed to withstand the high pressures generated within the fuel system, ensuring a secure and leak-free connection. They contribute to the overall efficiency of the fuel system by maintaining consistent fuel pressure and facilitating the precise delivery of fuel to the engine’s combustion chambers 1.

Role of the 4984462 High Pressure Fuel Fitting in Truck Operation

This Cummins part plays a specific role in the fuel system of a truck by providing a secure connection between the fuel rail and the fuel injectors. This fitting ensures that fuel is delivered at the correct pressure and volume to each injector, which is crucial for optimal engine performance. Its design allows for efficient fuel distribution, contributing to the engine’s power output and fuel efficiency 2.

Key Features of the 4984462 High Pressure Fuel Fitting

The 4984462 fitting is characterized by several key features that enhance its functionality. It is constructed from durable materials that can withstand the high pressures and temperatures of diesel fuel systems. The fitting’s design includes precision-machined surfaces to ensure a tight seal, minimizing the risk of leaks. Additionally, it is engineered to be compatible with a variety of fuel system components, ensuring versatility in its application 3.

Benefits of Using the 4984462 High Pressure Fuel Fitting

Incorporating this fitting into a truck’s fuel system offers several advantages. It improves fuel delivery by ensuring a consistent and precise flow of fuel to the injectors, which enhances engine efficiency. The fitting’s robust construction and secure connection contribute to the overall reliability of the fuel system, reducing the likelihood of fuel leaks and system failures. This results in improved engine performance and longevity 4.

Installation and Compatibility

Proper installation of the 4984462 fitting is crucial for its effective operation. It requires the use of specific tools and techniques to ensure a secure and leak-free connection. The fitting is designed to be compatible with a range of truck models and engine types, making it a versatile component for various applications. Detailed installation instructions should be followed to ensure optimal performance and safety .

Maintenance and Troubleshooting

Regular maintenance of the 4984462 fitting is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, and ensuring that all connections are secure. Common issues that may arise include leaks or reduced fuel pressure, which can often be addressed by tightening connections or replacing worn components. Following manufacturer guidelines for maintenance can help prevent these issues .

Safety Considerations

When working with high pressure fuel systems and the 4984462 fitting, it is important to follow safety protocols to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring that the fuel system is depressurized before performing any maintenance or repairs, and handling fuel with care to avoid spills or exposure to harmful vapors. Adhering to these safety considerations is crucial when working with high pressure fuel systems .

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial vehicle industry. The company’s commitment to excellence is reflected in its extensive product range and its focus on meeting the evolving needs of its customers.

Cummins High Pressure Fuel Fitting 4984462 Compatibility

The Cummins High Pressure Fuel Fitting part number 4984462 is designed to fit a range of Cummins engines. This fitting is integral for maintaining the integrity of the fuel system, ensuring that high-pressure fuel is delivered efficiently and safely.

Compatible Engines

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISZ13 CM2150 Z105

- QSX11.9 CM2250 ECF

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

Each of these engines relies on the 4984462 fitting to maintain the high-pressure fuel system’s integrity, ensuring that the engine performs optimally and reliably.

Role of Part 4984462 High Pressure Fuel Fitting in Engine Systems

The Part 4984462 High Pressure Fuel Fitting is an integral component in the fuel delivery system of advanced diesel engines, specifically within the XPI JV Systems used by Cummins HD and Scania HD engines. This fitting ensures a secure and leak-free connection between various high-pressure fuel components, facilitating efficient fuel delivery and maintaining system integrity.

Integration with Key Components

-

Fuel Pump and Fuel Pump Head:

- The high-pressure fuel fitting interfaces directly with the fuel pump and fuel pump head, allowing for the transfer of pressurized fuel from the pump to the subsequent components. This connection is vital for maintaining the required fuel pressure levels necessary for optimal engine performance.

-

Injector Plumbing:

- Within the injector plumbing system, the fitting plays a significant role in connecting the high-pressure fuel lines to the injectors. This ensures that each injector receives a consistent and precise amount of fuel, which is essential for combustion efficiency and emissions control.

-

Accumulator:

- The fitting is also used in conjunction with the accumulator, a component that helps in dampening pressure fluctuations within the fuel system. By providing a stable connection, the fitting assists in maintaining uniform fuel pressure, which is critical for the reliable operation of the injectors.

-

XPI JV Components:

- In the XPI JV system, the fitting is employed across various high-pressure components. Its role is to ensure that all connections within the system are secure and capable of withstanding the extreme pressures involved in modern diesel fuel injection systems.

-

Plumbing and Injectors:

- The fitting is a key element in the overall plumbing of the fuel system, connecting the pump to the injectors. This seamless integration ensures that fuel is delivered under high pressure directly to the combustion chambers, enhancing engine efficiency and performance.

By understanding the role of the Part 4984462 High Pressure Fuel Fitting within these complex engine systems, engineers and mechanics can better appreciate its importance in maintaining the integrity and efficiency of the fuel delivery process.

Conclusion

The 4984462 High Pressure Fuel Fitting is a critical component in the fuel systems of Cummins engines, ensuring efficient and reliable fuel delivery. Its robust design, compatibility with various engine models, and role in maintaining high-pressure fuel systems make it an essential part for optimal engine performance. Regular maintenance and adherence to safety protocols are crucial for the longevity and effectiveness of this fitting.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883503, ISB6.7 CM2150 SQ.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.