This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

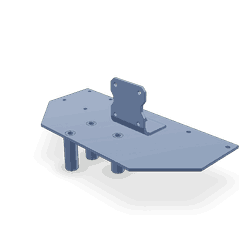

The Cummins 4933699 Water Transfer Tube is a component designed to facilitate the efficient transfer of coolant within the engine cooling system of commercial trucks. Its role is significant in maintaining the optimal operating temperature of the engine, which is vital for the performance and longevity of the vehicle 1.

Basic Concepts of Water Transfer Tubes

A Water Transfer Tube is a conduit that allows coolant to flow between different parts of the engine cooling system. Its function is to ensure that coolant is evenly distributed, which helps in dissipating heat generated by the engine. This process is crucial for maintaining the engine’s temperature within a safe range, preventing overheating and potential damage 2.

Purpose of the 4933699 Water Transfer Tube

This Cummins part plays a role in the operation of a truck by facilitating the movement of coolant from the engine block to the cylinder head and other critical areas. This ensures that all parts of the engine receive adequate cooling, which contributes to stable engine performance and helps in prolonging the engine’s lifespan by preventing thermal stress 3.

Key Features

The Cummins 4933699 is characterized by its robust design and the use of high-quality materials that are resistant to corrosion and wear. These features enhance its performance and durability, ensuring reliable operation under the demanding conditions typical of commercial truck use.

Benefits

Using this part can lead to improved engine cooling efficiency. This results in a reduced risk of overheating and contributes to enhanced overall engine performance. The tube’s design and materials also support its longevity, providing a reliable component for the cooling system.

Installation and Compatibility

Proper installation of the Water Transfer Tube involves following manufacturer guidelines to ensure it is correctly positioned and secured within the engine cooling system. It is designed to be compatible with specific truck models and engine types, ensuring a precise fit and function.

Maintenance and Troubleshooting

Regular maintenance practices for the Water Transfer Tube include checking for leaks, ensuring connections are secure, and inspecting for signs of wear or corrosion. Common issues may include blockages or damage to the tube, which can be addressed by cleaning or replacing the component as necessary.

Performance and Efficiency

The 4933699 contributes to the overall performance and efficiency of the truck’s engine cooling system by ensuring consistent coolant flow. This helps in maintaining optimal engine temperature, which is beneficial for engine efficiency and reliability.

Safety and Reliability

The design of the 4933699 incorporates safety features that enhance its reliability in various operating conditions. Its materials and construction are chosen to withstand the rigors of commercial truck use, providing a dependable component for the cooling system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in engine components. With a history of developing reliable and efficient parts, Cummins continues to be a trusted name in the industry, dedicated to advancing engine technology and performance 4.

Water Transfer Tube (Part 4933699) Compatibility with Cummins Engines

The Water Transfer Tube, identified by part number 4933699 and manufactured by Cummins, is a critical component in the cooling systems of various Cummins engines. This part facilitates the transfer of coolant between different parts of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

QSM11 Engines

The Water Transfer Tube is compatible with the QSM11 engine series. This engine is known for its robust design and reliability, often used in heavy-duty applications. The tube’s integration into the QSM11 engine ensures that coolant is effectively circulated, preventing overheating and extending the engine’s lifespan.

CM570 Engines

Similarly, the Water Transfer Tube is also designed to fit the CM570 engine series. The CM570 engine is another example of Cummins’ commitment to durability and performance. The tube’s role in this engine is crucial for maintaining the coolant flow, which is essential for the engine’s efficient operation and longevity.

Grouping of Engines

Both the QSM11 and CM570 engines benefit from the Water Transfer Tube’s design, which is tailored to meet the specific cooling requirements of these engines. The compatibility of part 4933699 with these engines underscores Cummins’ focus on providing high-quality, reliable components that enhance engine performance and reliability.

Role of Part 4933699 Water Transfer Tube in Engine Systems

The 4933699 is an essential component in the efficient operation of various engine systems. It facilitates the movement of water between different parts of the engine, ensuring optimal cooling and performance.

In conjunction with the Full Flow Oil Filter, the Water Transfer Tube plays a significant role in maintaining the engine’s temperature. The Full Flow Oil Filter is responsible for removing contaminants from the engine oil, ensuring that the oil remains clean and effective in lubricating engine components. The Water Transfer Tube, by efficiently circulating water, helps in dissipating the heat generated by the engine, which is vital for the oil filter’s performance.

The cooling effect provided by the Water Transfer Tube prevents the oil from overheating, which could otherwise lead to a breakdown of the oil’s lubricating properties. This, in turn, protects the Full Flow Oil Filter from being exposed to excessively hot oil, which could reduce its efficiency and lifespan.

Additionally, the Water Transfer Tube works in harmony with the engine’s cooling system components, such as the radiator and thermostat. It ensures that the water, after absorbing heat from the engine, is effectively transferred to the radiator where it can be cooled before being recirculated. This continuous cycle is essential for maintaining the engine’s operating temperature within safe limits.

Conclusion

In summary, the 4933699 is integral to the engine’s cooling system, working alongside components like the Full Flow Oil Filter to ensure the engine operates efficiently and remains protected from overheating. Its robust design, compatibility with various Cummins engines, and role in maintaining optimal engine temperature underscore its importance in the performance and longevity of commercial trucks.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5613211.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.