This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

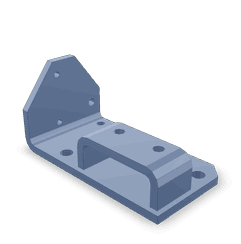

The Cummins 3625516 Filter Bracket is a component designed to support the mounting and stability of filters in commercial trucks. Its role is integral to the efficient operation of the truck’s filtration system, ensuring that filters are securely held in place and function optimally.

Purpose and Function

This Cummins part plays a role in the truck’s filtration system by providing a stable platform for the attachment of filters. This bracket ensures that filters are correctly positioned and remain secure during operation, which is vital for the effective filtration of fluids such as oil or fuel. By maintaining the proper alignment and stability of filters, the bracket contributes to the consistent performance of the filtration system 1.

Key Features

The design of the 3625516 Filter Bracket incorporates several characteristics that enhance its performance and durability. Crafted from high-strength materials, the bracket is engineered to withstand the rigors of commercial truck operation. Its design allows for easy attachment and detachment of filters, facilitating maintenance procedures. Additionally, the bracket’s construction includes features that protect against vibration and movement, ensuring that filters remain securely in place 2.

Benefits

The advantages provided by the 3625516 Filter Bracket include improved filter stability, which leads to more efficient filtration and reduced risk of filter displacement. The ease of installation is another benefit, as the bracket is designed to simplify the process of attaching and securing filters. Furthermore, by ensuring that filters are properly mounted, the bracket contributes to the overall efficiency of the filtration system, potentially extending the life of filters and reducing maintenance intervals 3.

Installation Process

Installing the 3625516 Filter Bracket involves several steps to ensure proper attachment and functionality. First, the area where the bracket will be installed should be cleaned and prepared. The bracket is then positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the filter housing. Using the appropriate tools, the bracket is secured in place, taking care to follow torque specifications to avoid over-tightening. Finally, the filter is attached to the bracket, and the system is checked for proper operation.

Maintenance and Troubleshooting

To maintain the 3625516 Filter Bracket, regular inspections should be conducted to ensure that it remains securely attached and shows no signs of damage or wear. Common issues that may arise include loosening of the bracket or damage from vibration. Troubleshooting methods may involve re-securing the bracket or replacing it if damage is detected. It is also important to ensure that filters are compatible with the bracket and are installed correctly to avoid performance issues.

Compatibility and Usage

The 3625516 Filter Bracket is designed to work with specific types of filters and truck models. It is important to consult the manufacturer’s guidelines for compatibility information to ensure optimal performance and safety. Specific usage guidelines may include recommendations for filter types, installation procedures, and maintenance schedules.

Safety Considerations

When installing or maintaining the 3625516 Filter Bracket, it is important to follow safety practices to prevent accidents or damage. This includes wearing appropriate personal protective equipment, ensuring the truck is properly supported if raised, and following torque specifications to avoid over-tightening. Additionally, ensuring that the filtration system is properly bled and checked for leaks after installation or maintenance is crucial for safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to quality is evident in its product offerings, including the 3625516 Filter Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Compatibility with Cummins Engines

The Cummins Filter Bracket part number 3625516 is designed to fit seamlessly with a variety of Cummins engines. This bracket is crucial for securing the engine’s air filter in place, ensuring optimal airflow and filtration efficiency. Here is a detailed look at its compatibility with specific Cummins engines:

4B3.9 Engine

The 4B3.9 engine benefits from the 3625516 filter bracket, which provides a robust mounting solution for the air filter. This bracket ensures that the air filter is securely fastened, preventing any movement that could disrupt the engine’s performance.

6B5.9 and 6C8.3 Engines

The 6B5.9 and 6C8.3 engines also utilize the 3625516 filter bracket. This bracket is engineered to fit the specific design and mounting points of these engines, ensuring a snug and reliable fit. The bracket’s design accommodates the unique layout of these engines, providing a stable platform for the air filter.

Grouping of Engines

The 3625516 filter bracket is compatible with the 4B3.9 engine as well as the 6B5.9 and 6C8.3 engines. These engines, while distinct in their specifications, share a commonality in their need for a reliable air filter mounting solution. The bracket’s design is versatile enough to fit these engines, ensuring that the air filter remains securely in place, regardless of the engine type.

Role of Part 3625516 Filter Bracket in Engine Systems

The 3625516 Filter Bracket is an essential component in the assembly and securement of the fuel filter within various engine systems. This bracket ensures that the fuel filter is correctly positioned and maintained in place, allowing for efficient filtration of the fuel before it reaches the engine.

When integrating the Filter Bracket with the fuel filter, it is important to consider the following components and their interactions:

-

Fuel Lines: The Filter Bracket facilitates the connection of fuel lines to the fuel filter. It ensures that the lines are properly aligned and secured, minimizing the risk of leaks and maintaining consistent fuel flow.

-

Mounting Points: The bracket is designed to interface with specific mounting points on the engine or chassis. This secure attachment is vital for withstanding the vibrations and movements inherent in engine operation.

-

Fuel Pump: In systems where the fuel filter is located before the fuel pump, the Filter Bracket helps maintain the structural integrity of the fuel delivery system. It ensures that the filter does not shift, which could otherwise impede fuel flow or cause damage to the pump.

-

Fuel Tank: In some configurations, the fuel filter is mounted near the fuel tank. The Filter Bracket plays a role in keeping the filter stable and correctly oriented relative to the tank, enhancing the overall efficiency of the fuel system.

-

Engine Bay Components: The bracket must be compatible with surrounding components within the engine bay. This includes clearance from moving parts and compatibility with other brackets or mounts to ensure a cohesive and functional assembly.

Proper installation of the Filter Bracket is fundamental to the reliable operation of the fuel filtration system, directly influencing the performance and longevity of the engine.

Conclusion

The Cummins 3625516 Filter Bracket is a critical component for the efficient operation of commercial truck filtration systems. Its design ensures secure mounting and stability of filters, contributing to the overall performance and longevity of the engine. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.