This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

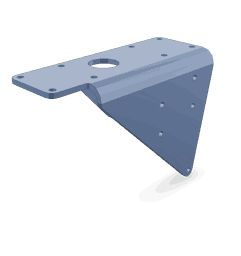

The Cummins 3284948 Filter Bracket is a component designed for use in commercial trucks. It serves a specific role within the truck’s filtration system, ensuring the proper mounting and stability of filters. This bracket is integral to maintaining the efficiency and reliability of the truck’s engine by supporting essential filtration processes 1.

Purpose and Function

This Cummins part plays a role in the truck’s filtration system by providing a secure mounting point for filters. It ensures that filters are held firmly in place, which is vital for the effective operation of the filtration system. The stability provided by the bracket helps maintain the integrity of the filtration process, allowing for optimal performance of the engine 2.

Key Features

The 3284948 Filter Bracket is characterized by its robust design and durable materials. It is engineered to withstand the rigors of commercial truck operations, offering long-lasting performance. The bracket’s design includes features that enhance its ability to securely hold filters in place, contributing to the overall efficiency of the filtration system 3.

Benefits

Using this part offers several advantages. It provides improved filter stability, which is crucial for the consistent performance of the filtration system. Additionally, the bracket’s design facilitates ease of maintenance, allowing for straightforward filter replacement and system checks. This contributes to the overall efficiency and reliability of the truck’s engine system 4.

Installation Process

Installing the Cummins 3284948 Filter Bracket involves several steps to ensure proper setup. Begin by identifying the correct mounting location on the truck. Use the appropriate tools to secure the bracket in place, ensuring it is firmly attached. Once installed, verify that the bracket is stable and that filters can be mounted securely. Follow the manufacturer’s guidelines for any additional components or adjustments required during installation.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3284948 Filter Bracket, regular maintenance is recommended. Inspect the bracket periodically for signs of wear or damage. Ensure that it remains securely attached and that filters are properly mounted. Cleaning the bracket and surrounding area can help prevent buildup that might affect performance. Adhering to these maintenance practices will help maintain the efficiency of the filtration system.

Troubleshooting Common Issues

Common issues with filter brackets may include loose mounting, damage to the bracket, or filters not seating properly. To address these problems, first, check the mounting screws and bolts to ensure they are tight. Inspect the bracket for any signs of damage or wear and replace it if necessary. Ensure that filters are correctly aligned and seated in the bracket. Regular maintenance and inspections can help identify and resolve these issues promptly.

Manufacturer Information

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins provides solutions that enhance the performance and reliability of commercial vehicles. The company’s reputation is built on its commitment to delivering durable, high-performance parts that meet the demanding requirements of the industry.

Conclusion

The Cummins 3284948 Filter Bracket is a vital component in the maintenance and operation of commercial truck engines. Its robust design, ease of maintenance, and critical role in the filtration system make it an essential part for ensuring the efficiency and reliability of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.