This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3251854 Filter Bracket is a component designed for use in commercial trucks. It serves a specific role within the vehicle’s filtration system, ensuring the proper mounting and stability of filters. This bracket is integral to maintaining the efficiency and reliability of the truck’s engine by supporting essential filtration processes.

Purpose and Function

The Cummins 3251854 Filter Bracket plays a role in the truck’s filtration system by providing a secure mounting point for filters. It ensures that filters are held firmly in place, which is vital for the consistent operation of the filtration system. This stability helps in maintaining the flow of clean fluids through the engine, contributing to its overall performance and longevity 1.

Key Features

The design of the Cummins 3251854 Filter Bracket incorporates several characteristics that enhance its performance and durability. It is constructed from materials that offer resistance to corrosion and wear, ensuring longevity in various operating conditions. The bracket’s design allows for easy attachment and detachment of filters, facilitating maintenance procedures.

Benefits

The Cummins 3251854 Filter Bracket offers several advantages. It provides improved filter stability, which is crucial for the effective operation of the filtration system. The ease of installation is another benefit, allowing for quick replacement or maintenance of filters. Additionally, by ensuring filters are securely mounted, the bracket contributes to the overall efficiency of the filtration system, helping to maintain engine health.

Installation Process

Installing the Cummins 3251854 Filter Bracket involves several steps to ensure it is properly secured and functions as intended. The process begins with the removal of the old bracket, if present. The new bracket is then aligned with the mounting points on the truck’s frame. Using the appropriate tools, it is fastened securely in place. Finally, the filters are attached to the bracket, ensuring they are correctly positioned and tightened to the manufacturer’s specifications.

Maintenance and Troubleshooting

Maintaining the Cummins 3251854 Filter Bracket involves regular inspection for signs of wear or damage. Common issues may include corrosion or loosening of the bracket, which can affect filter stability. Troubleshooting steps include tightening any loose components, cleaning the bracket to remove debris, and replacing it if significant wear is detected. Regular maintenance helps ensure the bracket continues to support the filtration system effectively.

Safety Considerations

When installing or maintaining the Cummins 3251854 Filter Bracket, it is important to follow safety guidelines to protect mechanics and operators. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked and the engine is off before beginning work. Additionally, using the correct tools and following the manufacturer’s instructions can help prevent accidents and ensure the bracket is installed correctly 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s products are known for their reliability and efficiency, contributing to the performance and longevity of vehicles and equipment across various industries.

Compatibility

The Cummins Filter Bracket part number 3251854 is designed to securely hold and position the air filter within the engine’s air intake system. This bracket ensures that the air filter is properly aligned and sealed, which is essential for maintaining optimal engine performance and efficiency.

N14 Mechanical Engines

The Cummins Filter Bracket 3251854 is specifically engineered to fit the N14 Mechanical engine series. This engine is renowned for its robust construction and reliability, making it a popular choice in various heavy-duty applications. The bracket’s design ensures that it can withstand the rigors of continuous operation in demanding environments.

Group Compatibility

In addition to the N14 Mechanical engines, the Cummins Filter Bracket 3251854 is also compatible with other Cummins engine groups where similar design and mounting requirements are present. This ensures that the bracket can be used across a range of applications, providing a standardized solution for securing the air filter.

Installation and Functionality

Proper installation of the Cummins Filter Bracket 3251854 is critical for maintaining the integrity of the engine’s air intake system. The bracket’s design allows for easy attachment to the engine’s mounting points, ensuring that the air filter remains securely in place. This is essential for preventing air leaks and ensuring that the engine receives a consistent supply of clean air, which is vital for efficient combustion and overall engine performance.

By ensuring that the air filter is properly positioned and sealed, the Cummins Filter Bracket 3251854 helps to maintain the engine’s efficiency and longevity, making it an essential component for any Cummins engine setup.

Role in Engine Systems

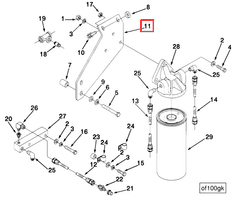

The Filter Bracket, identified by part number 3251854, is an essential component in the assembly and functionality of various engine systems. This bracket is specifically designed to support and secure the filter and mounting bracket, ensuring stability and proper alignment within the engine compartment.

Integration with Bypass Filter and EBM Filter

When integrating with the bypass filter and EBM (Electronically Controlled Bypass Module) filter, the Filter Bracket provides a robust mounting solution. It ensures that these filters are held firmly in place, preventing any movement that could lead to leaks or inefficient filtration. The secure attachment allows for optimal performance of the bypass filter, which is responsible for diverting a portion of the oil flow to maintain lubrication under high-stress conditions.

Supporting Bypass Oil System

In systems utilizing a bypass oil filtration setup, the Filter Bracket plays a significant role. It supports the additional filter media required for the bypass oil system, ensuring that the oil is effectively filtered before re-entering the main lubrication circuit. This setup enhances the overall cleanliness of the oil, prolonging the life of engine components and maintaining efficient operation.

Ensuring Stability of Filter and Mounting Bracket Assembly

The Filter Bracket is instrumental in the stability of the filter and mounting bracket assembly. By providing a solid foundation, it allows for easy maintenance and replacement of filters without the risk of dislodging other components. This stability is particularly important in high-vibration environments typical of engine compartments, where unsecured components can lead to failures or reduced efficiency.

Conclusion

In summary, the Filter Bracket (part 3251854) is a key component in the effective operation of engine filtration systems. Its role in supporting and securing filters ensures that the engine maintains optimal performance and longevity 3.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.