This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

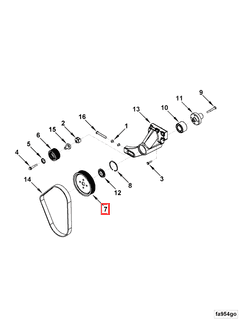

The Fan Pulley Assembly 4940055 by Cummins is a component designed to facilitate the operation of heavy-duty trucks. This assembly is integral to the engine cooling system, ensuring that the engine maintains optimal operating temperatures under various conditions. Its role in the cooling process is significant, contributing to the overall efficiency and reliability of the truck’s engine 1.

Basic Concepts of Fan Pulley Assembly

Fan pulley assemblies are designed to drive the engine’s cooling fan. They are part of the engine’s accessory drive system, which includes various pulleys and belts that transfer power from the engine to different components. The fan pulley assembly specifically connects the engine to the cooling fan, allowing the fan to rotate and draw air through the radiator to cool the engine. This interaction is vital for maintaining the engine’s temperature within a safe range, preventing overheating and potential damage 2.

Purpose of the 4940055 Fan Pulley Assembly

This Cummins part plays a role in the operation of a truck by facilitating the rotation of the cooling fan. This rotation is crucial for dissipating heat from the engine, ensuring that it operates within its designed temperature range. By maintaining optimal engine temperature, the assembly contributes to the engine’s overall performance, efficiency, and longevity. It is a component that works in conjunction with the radiator, thermostat, and other cooling system parts to regulate engine temperature.

Key Features

The 4940055 is constructed with materials and design elements that enhance its functionality and durability. It is made from high-strength materials to withstand the rigors of heavy-duty truck operation. The design includes precision-machined surfaces for smooth belt operation and robust mounting points to secure the assembly to the engine. Additionally, the assembly may feature unique attributes such as a variable speed design, which allows for efficient cooling at different engine speeds, optimizing fuel efficiency and performance.

Benefits

The advantages provided by this part include improved engine efficiency, durability, and reliability across various operating conditions. Its design and construction contribute to a more effective cooling system, which can lead to better engine performance and longevity. The assembly’s ability to maintain optimal engine temperature under different loads and speeds ensures that the engine operates efficiently, reducing the risk of overheating and associated damage.

Installation Process

Installing the Fan Pulley Assembly requires following a series of steps to ensure proper fitment and function. Preparatory steps include ensuring the engine is cool and the cooling system is depressurized. The necessary tools for installation may include a socket set, wrenches, and a belt tensioner tool. The installation process involves aligning the pulley with the engine’s accessory drive system, securing it in place, and ensuring the belt is correctly tensioned. Best practices for installation include verifying all connections are tight and the belt is properly aligned to prevent slippage or damage.

Maintenance Tips

To prolong the lifespan of the Fan Pulley Assembly, routine maintenance practices are recommended. These include regular inspections for signs of wear or damage, ensuring the belt is properly tensioned, and lubricating moving parts as necessary. Replacement schedules should be followed based on the manufacturer’s recommendations or when signs of significant wear are observed. Proper maintenance ensures the assembly continues to function effectively, contributing to the engine’s cooling efficiency and overall performance.

Troubleshooting Common Issues

Common problems associated with fan pulley assemblies can include belt slippage, unusual noises, or visible wear on the pulley or belt. Diagnostic procedures for these issues may involve inspecting the belt tension, checking for alignment issues, and examining the pulley and belt for signs of wear or damage. Potential solutions include adjusting the belt tension, realigning components, or replacing worn parts. Addressing these issues promptly can prevent more significant problems and ensure the cooling system operates efficiently.

Compatibility and Applications

The Fan Pulley Assembly is designed for compatibility with specific Cummins engine models, ensuring it meets the performance and durability requirements of these engines. Its applications extend to various types of heavy-duty trucks, where it plays a vital role in the engine cooling system. Understanding the compatibility and applications of this assembly is important for ensuring it is the correct fit for the intended engine and truck model.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly for its diesel engines and components. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks.

Fan Pulley Assembly Part 4940055 Compatibility with Cummins Engines

The Fan Pulley Assembly part number 4940055, manufactured by Cummins, is designed to fit seamlessly with specific models of Cummins engines. This part is crucial for the proper functioning of the engine’s cooling system, ensuring that the fan operates efficiently to maintain optimal engine temperature.

QSB6.7 CM850 (CM2850) Engine

The Fan Pulley Assembly part 4940055 is compatible with the QSB6.7 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The fan pulley assembly ensures that the cooling fan is securely attached to the engine, facilitating effective airflow and preventing overheating.

QSB7 CM2880 B117 Engine

Similarly, the Fan Pulley Assembly part 4940055 is also compatible with the QSB7 CM2880 B117 engine. This engine model is engineered for high performance and durability, often used in demanding industrial and commercial applications. The fan pulley assembly is integral to the engine’s cooling system, ensuring that the fan operates smoothly and efficiently, thereby maintaining the engine’s temperature within safe limits.

By ensuring a secure fit and reliable operation, the Fan Pulley Assembly part 4940055 plays a vital role in the overall performance and longevity of these Cummins engines.

Role of Part 4940055 Fan Pulley Assembly in Engine Systems

The part 4940055 Fan Pulley Assembly is an integral component in the efficient operation of engine systems, specifically in the interaction between the drive system and the fan.

When the engine is operational, the drive system, typically powered by the crankshaft via a belt or chain, imparts rotational motion to the fan pulley assembly. This rotational motion is then transferred to the fan, which is mounted on the same shaft as the pulley.

The fan, in turn, moves air across the radiator and other heat exchangers, facilitating the dissipation of heat generated by the engine. This cooling process is essential for maintaining optimal engine temperature and ensuring the longevity and efficiency of the engine components.

The fan pulley assembly acts as the intermediary, ensuring that the rotational force from the drive is effectively translated into the necessary airflow by the fan. Its proper function is therefore essential for the overall thermal management of the engine system.

Conclusion

The Fan Pulley Assembly 4940055 by Cummins is a critical component in the engine cooling system of heavy-duty trucks. Its design and functionality contribute to the efficient operation and longevity of the engine by ensuring optimal temperature management. Proper installation, maintenance, and troubleshooting of this part are essential for maintaining the overall performance and reliability of the truck’s engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.