The Cummins C0131029700 Fan Hub is a component designed for use in the engine cooling systems of heavy-duty trucks. Its purpose is to facilitate efficient airflow through the radiator, helping to maintain optimal engine temperature under various operating conditions.

Basic Concepts of a Fan Hub

Fan hubs are integral to the cooling systems of vehicles, particularly in heavy-duty applications. They operate by controlling the speed of the cooling fan based on the engine’s temperature. This is achieved through a thermostatic clutch mechanism that engages and disengages the fan as needed. The significance of fan hubs lies in their ability to enhance engine efficiency by ensuring that the engine operates within its ideal temperature range, thereby preventing overheating and potential damage 1.

Purpose of the Cummins C0131029700 Fan Hub

The Cummins C0131029700 Fan Hub plays a specific role in the operation of a truck by regulating the speed of the cooling fan. It is designed to engage the fan when the engine temperature rises above a certain threshold, ensuring that adequate airflow is maintained through the radiator. This function is vital for dissipating heat and maintaining engine temperature within safe limits, especially under heavy loads or in high ambient temperatures 2.

Key Features

The Cummins C0131029700 Fan Hub is characterized by several key features that enhance its performance. Its design incorporates a robust construction that is capable of withstanding the rigors of heavy-duty use. The materials used in its construction are selected for their durability and resistance to wear. Additionally, the hub features a precise thermostatic control mechanism that ensures accurate and reliable fan operation 3.

Benefits

The advantages provided by the Cummins C0131029700 Fan Hub include improved engine efficiency, as it helps maintain optimal operating temperatures. This can lead to enhanced fuel economy and reduced emissions. Furthermore, the hub contributes to the longevity and reliability of the engine by preventing overheating, which can cause severe damage. Its robust design and high-quality materials also ensure durability and consistent performance over time 4.

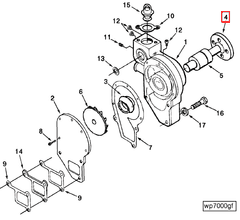

Installation Process

Proper installation of the Cummins C0131029700 Fan Hub involves several steps. First, the old fan hub should be removed, taking care to note the orientation and connections. The new hub should then be aligned with the fan and secured in place. It is important to ensure that all connections are tight and that the thermostatic clutch is properly engaged. Following the manufacturer’s guidelines for torque specifications and alignment is crucial for optimal performance.

Common Issues and Troubleshooting

Frequent problems associated with fan hubs can include clutch failure, bearing wear, and electrical issues. Troubleshooting methods may involve inspecting the clutch for signs of wear or damage, checking the bearings for smoothness of operation, and ensuring that all electrical connections are secure and free from corrosion. Solutions may range from simple adjustments to replacement of worn components.

Maintenance Tips

Regular maintenance practices for the Cummins C0131029700 Fan Hub include periodic inspection of the clutch and bearings for signs of wear. Lubrication of moving parts, where applicable, and ensuring that all electrical connections are clean and secure can help maintain optimal performance. Additionally, monitoring the engine’s temperature under various conditions can provide early indications of potential issues with the fan hub.

Performance Under Various Conditions

The Cummins C0131029700 Fan Hub is designed to perform effectively under a range of operating conditions. In extreme temperatures, its thermostatic control mechanism ensures that the fan operates only when necessary, conserving energy and enhancing efficiency. Under heavy loads, the hub engages the fan to provide additional cooling, helping to maintain engine temperature within safe limits.

Comparison with Other Fan Hubs

When compared to similar products from other manufacturers, the Cummins C0131029700 Fan Hub stands out for its robust design, precise thermostatic control, and durable construction. While other fan hubs may offer similar functions, the Cummins hub is recognized for its reliability and performance in heavy-duty applications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. Its product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles and equipment.

Understanding the Role of C0131029700 Fan Hub in Engine Systems

The C0131029700 Fan Hub is an integral component in various engine systems, facilitating efficient operation and performance. Its role is to connect and synchronize several key components, ensuring optimal functionality and balance within the engine.

Integration with Adapters and Drives

The Fan Hub works in conjunction with the Adapter to ensure a secure and precise fit within the engine assembly. This connection is vital for maintaining the structural integrity and alignment of the fan system. Additionally, the Front Drive and Fan Drive components rely on the Fan Hub to transmit rotational force from the engine to the fan blades. This transmission is essential for dissipating heat generated by the engine, maintaining optimal operating temperatures.

Coordination with Fan Brackets

The Fan Bracket is another component that interfaces with the Fan Hub. This bracket provides the necessary support and positioning for the fan assembly, allowing it to operate effectively within the engine bay. The Fan Hub ensures that the fan bracket remains aligned and stable, which is important for the consistent performance of the cooling system.

Functionality with Various Water Pumps

The Fan Hub is designed to work with a range of Water Pumps, including the Water Pump - Long Life, Water Pump - S2 TK, and Water Pump - Ford (FOV). Each of these water pumps has specific requirements and operational characteristics, and the Fan Hub ensures seamless integration and operation.

For instance, the Water Pump - L1 and Water Pump - L2 are designed for different engine configurations, and the Fan Hub accommodates these variations, ensuring that the water pump operates within its designed parameters. Similarly, the Water Pump - S1 and Water Pump - S2 benefit from the precise fit and alignment provided by the Fan Hub, enhancing the efficiency of coolant circulation.

Specialized Applications

In systems utilizing the Water Pump - Low Fan Counter or the Water Pump Kit, the Fan Hub plays a role in maintaining the correct rotational speed and direction. This is particularly important in engines where counter-rotation is required to optimize cooling efficiency and reduce mechanical stress.

The Water Pump Repair Kit and Water Pump - IND LFC also interface with the Fan Hub, ensuring that any repairs or replacements are carried out with minimal disruption to the engine’s cooling system. This compatibility is essential for maintaining the longevity and reliability of the engine.

Low Fan Ratio Drive

The Low Fan Ratio-1.07 Drive is a specialized component that requires precise engagement with the Fan Hub. This drive ratio is designed to operate the fan at a lower speed relative to the engine, reducing noise and improving fuel efficiency while still providing adequate cooling. The Fan Hub ensures that this ratio is maintained, contributing to the overall performance and efficiency of the engine.

Conclusion

In summary, the Cummins C0131029700 Fan Hub is a versatile and essential component that enhances the functionality and efficiency of various engine systems. Its role in connecting and synchronizing critical components like adapters, drives, brackets, and water pumps is fundamental to the optimal operation of the engine’s cooling system.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.