This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

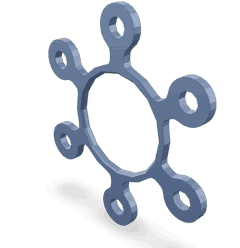

The Cummins 3406706 Fan Spacer is a component designed to enhance the cooling system of heavy-duty trucks. Its purpose is to maintain optimal engine temperature by ensuring efficient airflow through the radiator. This part plays a role in the cooling system by providing the necessary spacing between the fan and the radiator, which is crucial for effective heat dissipation 1.

Basic Concepts of Fan Spacers

A fan spacer is a device used in engine cooling systems to create the appropriate distance between the fan and the radiator. This spacing is vital for ensuring that the fan can effectively draw air through the radiator, thereby cooling the engine. The spacer helps in maintaining the alignment and efficiency of the fan, which contributes to the overall cooling performance of the engine 2.

Purpose of the 3406706 Fan Spacer

The Cummins 3406706 Fan Spacer is specifically designed to fit within the cooling system of heavy-duty trucks. It is positioned between the fan and the radiator, where it plays a role in ensuring that the fan operates at the correct distance from the radiator. This setup aids in efficient engine cooling by allowing for optimal airflow and reducing the risk of overheating 1.

Key Features

The Cummins 3406706 Fan Spacer is constructed from durable materials that can withstand the high temperatures and pressures within the engine compartment. Its design includes precise dimensions to ensure a proper fit and effective performance. Additionally, the spacer may feature unique characteristics such as heat-resistant coatings or reinforced structures to enhance its durability and efficiency 3.

Benefits of Using the 3406706 Fan Spacer

Using the Cummins 3406706 Fan Spacer offers several advantages. It contributes to improved engine efficiency by ensuring that the cooling system operates at peak performance. This can lead to reduced wear on cooling system components and enhanced overall performance of the truck. Additionally, the spacer helps in maintaining consistent engine temperatures, which is beneficial for the longevity of the engine 1.

Installation Process

Installing the Cummins 3406706 Fan Spacer involves several steps to ensure proper fitting. Begin by locating the correct position between the fan and the radiator. Use the appropriate tools to secure the spacer in place, ensuring that it is aligned correctly. It is important to follow the manufacturer’s guidelines to avoid any issues during installation 2.

Troubleshooting Common Issues

Common problems associated with fan spacers include noise, vibration, or cooling inefficiencies. These issues can often be traced back to improper installation or wear and tear. To address these problems, inspect the spacer for any signs of damage or misalignment. Repositioning or replacing the spacer may be necessary to resolve these issues 3.

Maintenance Tips

Regular maintenance of the Cummins 3406706 Fan Spacer is important for ensuring its longevity and optimal performance. Inspect the spacer at regular intervals for any signs of wear or damage. Cleaning the spacer to remove any debris or buildup can also help in maintaining its efficiency. Following these maintenance practices will contribute to the overall reliability of the cooling system 1.

About Cummins

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry. With a rich history of innovation and quality, Cummins offers a wide range of products designed to meet the demands of various applications. The company is known for its commitment to excellence and its reputation for producing reliable and high-performance components.

Role of Part 3406706 Fan Spacer in Engine Systems

The part 3406706 Fan Spacer is an essential component in the assembly and operation of various engine systems. It is specifically designed to maintain the correct spacing between the fan and other components, ensuring optimal performance and efficiency.

Interaction with the Fan Pilot

When integrated with the fan pilot, the fan spacer ensures that the fan operates within the precise parameters required for effective air circulation. This spacing is vital for maintaining the balance between the fan’s rotational speed and the airflow it generates. Proper spacing prevents undue stress on the fan pilot mechanism, which can lead to premature wear or failure 2.

Ensuring Component Alignment

The fan spacer also plays a significant role in aligning the fan with other engine components. Accurate alignment is necessary to prevent vibrations and ensure smooth operation. This alignment is particularly important in high-performance engines where even minor discrepancies can lead to significant issues over time 3.

Thermal Management

By maintaining the correct distance between the fan and heat-generating components, the fan spacer contributes to effective thermal management. This spacing allows for efficient cooling, which is essential for the longevity and reliability of the engine system. Proper cooling prevents overheating, which can cause damage to both the fan and surrounding components 1.

Noise Reduction

Another important function of the fan spacer is noise reduction. By ensuring that the fan operates within its designed parameters, the spacer helps minimize the noise generated during engine operation. This is particularly beneficial in applications where noise levels need to be kept to a minimum, such as in residential or commercial settings 2.

Structural Integrity

The fan spacer also contributes to the structural integrity of the engine assembly. It helps distribute loads evenly across the fan and connected components, reducing the risk of mechanical failure. This is especially important in engines that operate under high stress conditions 3.

Conclusion

In summary, the Cummins 3406706 Fan Spacer is a key component that enhances the performance, reliability, and efficiency of engine systems by ensuring proper spacing, alignment, thermal management, noise reduction, and structural integrity. Regular maintenance and proper installation are crucial for maximizing the benefits of this part.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ ↩ ↩ ↩ ↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Elsevier Ltd, 2011.

↩ ↩ ↩ ↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.