This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3200352 Fan Pulley is a critical component for commercial trucks, integral to the engine’s cooling system. It facilitates the operation of the cooling fan, ensuring the engine maintains optimal operating temperatures across various driving conditions.

Basic Concepts of a Fan Pulley

A fan pulley is a mechanical device that transfers rotational force from the engine to the cooling fan. It operates within the engine cooling system, working alongside the fan clutch and radiator to regulate engine temperature. The pulley’s design allows it to adjust the speed of the cooling fan based on the engine’s needs, enhancing cooling efficiency and reducing unnecessary strain on the engine 1.

Purpose of the 3200352 Fan Pulley

This part connects the engine to the cooling fan, enabling the fan to rotate and draw air through the radiator. This process helps dissipate heat from the engine coolant, maintaining the engine within its optimal temperature range. Efficient heat management contributes to the overall performance and longevity of the engine 2.

Key Features

The 3200352 is characterized by its robust design and the materials used in its construction, which enhance its durability and performance. It is engineered to withstand the rigors of commercial truck operation, featuring a precision-machined surface for smooth operation and resistance to wear. Additionally, its design may include features that reduce noise and vibration, contributing to a quieter and more comfortable driving experience.

Benefits

The advantages of this Cummins part include improved engine cooling efficiency, which can lead to enhanced engine performance and reliability. By ensuring the engine operates within its optimal temperature range, the pulley helps reduce wear on associated components, potentially leading to lower maintenance costs. Furthermore, efficient cooling can contribute to better fuel economy, offering potential savings over time 3.

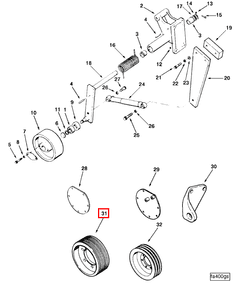

Installation Process

Installing the 3200352 requires careful attention to detail to ensure proper fitting and operation. The process involves removing the old pulley, cleaning the mounting area, and securing the new pulley in place using the appropriate tools. It is important to follow manufacturer guidelines for torque specifications and alignment to ensure the pulley functions correctly within the engine cooling system.

Troubleshooting Common Issues

Common problems associated with fan pulleys include noise, vibration, or overheating. These issues can often be traced back to improper installation, wear and tear, or failure of associated components such as the fan clutch. Diagnostic steps may involve inspecting the pulley and related parts for signs of damage or misalignment, ensuring all components are correctly installed and functioning as intended.

Maintenance Tips

To prolong the lifespan of the 3200352, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the pulley and surrounding areas to remove debris, and ensuring all connections are secure. Replacement should be considered if the pulley shows significant wear or if cooling efficiency declines, to maintain optimal engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry, offering products that are known for their reliability, performance, and efficiency.

Compatibility

This Cummins part is designed to be compatible with several engine models, ensuring efficient operation and longevity. It is compatible with the K19 series and a broader group of engines, providing the necessary support for the cooling system. This compatibility ensures that the fan operates smoothly, maintaining optimal engine temperature and preventing overheating.

Key Considerations

When installing the 3200352, it is crucial to ensure that the part is correctly aligned and securely fastened. Proper installation is essential for the longevity of the part and the overall efficiency of the engine’s cooling system. Regular maintenance checks should be performed to ensure that the fan pulley remains in good condition and continues to function as intended.

Role of 3200352 in Engine Systems

This part is an integral component in the efficient operation of engine systems, specifically in the interaction between the drive system and the fan. When the engine is operational, the drive system, typically powered by the crankshaft via a belt or chain, imparts rotational motion to the fan pulley. This pulley is designed to transfer this motion to the fan blades. As the pulley rotates, it drives the fan, which is responsible for drawing air through the radiator to cool the engine.

The efficiency of this transfer is dependent on the precise engineering of the fan pulley. It must maintain a consistent speed ratio between the engine’s rotational speed and the fan’s rotational speed. This ensures that the fan operates at an optimal speed for effective cooling, without unnecessarily increasing the engine’s workload.

Moreover, the fan pulley’s design allows for adjustments in fan speed, which can be crucial during varying engine loads or ambient temperatures. This adaptability helps in maintaining the engine’s temperature within a safe operating range, enhancing the overall performance and longevity of the engine system.

Conclusion

The Cummins 3200352 Fan Pulley plays a vital role in maintaining the optimal operating temperature of commercial truck engines. Its robust design, compatibility with various engine models, and the benefits it offers in terms of engine performance and fuel efficiency make it a crucial component for any commercial truck operator. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.