This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3024660 Fan Spindle is a component designed to facilitate efficient cooling in heavy-duty trucks. It is integral to the engine cooling system, ensuring that the engine operates within optimal temperature ranges under various conditions.

Basic Concepts of Fan Spindles

A fan spindle is a mechanical component that supports and rotates the cooling fan within an engine’s cooling system. Its primary function is to drive the fan, which circulates air through the radiator to dissipate heat generated by the engine. In commercial trucks, the fan spindle must withstand significant stress and operate reliably across a wide range of temperatures and loads 1.

Purpose of the 3024660 Fan Spindle

The Cummins 3024660 Fan Spindle plays a role in the operation of a truck by maintaining optimal engine temperature. It ensures that the cooling fan operates efficiently, which is vital for dissipating heat and preventing engine overheating. This component contributes to the overall efficiency and reliability of the truck’s cooling system.

Key Features

The Cummins 3024660 Fan Spindle is characterized by its robust design and the use of high-quality materials. These features enhance its performance and durability. The spindle is engineered to handle the demanding conditions typical of heavy-duty truck operations, ensuring long-lasting and reliable performance.

Benefits

Using the Cummins 3024660 Fan Spindle offers several advantages. It contributes to improved engine performance by ensuring efficient cooling, which helps maintain engine efficiency and power output. Additionally, its durable construction enhances the reliability of the cooling system, reducing the likelihood of failures and extending the component’s service life.

Installation Process

Proper installation of the Cummins 3024660 Fan Spindle involves several steps. It is important to ensure that the engine is cool before beginning the installation. The process includes removing the old spindle, cleaning the mounting area, and securely installing the new spindle. Appropriate tools and precautions should be used to avoid damage to the component or the engine.

Troubleshooting Common Issues

Common issues with fan spindles include noise, vibration, or failure to operate. These problems can often be traced to wear and tear, misalignment, or mechanical failures. Troubleshooting steps may involve inspecting the spindle for damage, ensuring proper alignment, and checking for any obstructions or debris that could affect its operation.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and efficient operation of the Cummins 3024660 Fan Spindle. This includes periodic inspections for wear or damage, ensuring proper lubrication, and checking for any signs of misalignment. Adhering to recommended maintenance schedules can help prevent unexpected failures and extend the component’s service life.

Performance Under Various Conditions

The Cummins 3024660 Fan Spindle is designed to perform reliably under a variety of operating conditions. It can handle extreme temperatures, heavy loads, and varying speeds, making it suitable for the demanding environments in which heavy-duty trucks often operate. Its robust design ensures consistent performance, contributing to the overall reliability of the truck’s cooling system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s expertise in engine components, including the Cummins 3024660 Fan Spindle, underscores its dedication to providing reliable and high-performance solutions for its customers.

Fan Spindle Part 3024660 Compatibility with Cummins Engines

The Fan Spindle part number 3024660, manufactured by Cummins, is a critical component in various engine configurations. This part is designed to ensure the proper functioning of the engine’s cooling system by facilitating the rotation of the cooling fan.

K19 Engine Group

The Fan Spindle part 3024660 is compatible with the K19 engine series. This engine series is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The K19 engine’s cooling system relies on the efficient operation of the fan spindle to maintain optimal engine temperatures, ensuring longevity and performance.

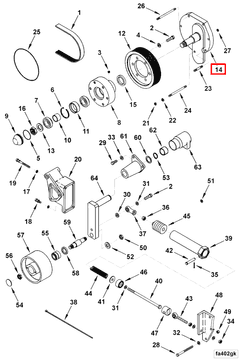

In the K19 engine, the fan spindle is integral to the cooling fan assembly. It connects the fan blades to the fan motor, allowing for smooth and consistent rotation. This ensures that the cooling fan can effectively draw air through the radiator, dissipating heat generated by the engine. The precise fit and durability of the Fan Spindle part 3024660 are crucial for maintaining the integrity of the cooling system in the K19 engine.

The compatibility of the Fan Spindle part 3024660 with the K19 engine underscores Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance and durability.

Understanding the Role of Part 3024660 Fan Spindle in Engine Systems

The part 3024660 Fan Spindle is an integral component in the efficient operation of various engine systems. It serves as the central axis around which several key components rotate and interact, ensuring the smooth functioning of the engine’s cooling and air management systems.

Interaction with the Drive System

The fan spindle is directly connected to the engine’s drive system. This connection allows the spindle to transfer rotational force from the engine to the fan, enabling it to spin at the necessary speed to facilitate effective cooling. The drive system, typically comprising a belt or chain mechanism, relies on the spindle’s precise alignment and smooth operation to maintain consistent performance.

Functionality within the Fan Assembly

At the heart of the fan assembly, the spindle supports the fan blades, allowing them to rotate and draw air through the engine’s cooling system. The spindle’s design ensures minimal friction and maximum efficiency, which is essential for maintaining optimal engine temperature under varying operational conditions.

Integration with the Fan Drive Arrangement

The fan drive arrangement, which may include components such as clutches or variable speed drives, depends on the spindle for stable and reliable operation. The spindle’s role in this arrangement is to provide a consistent axis of rotation, which is crucial for the effective engagement and disengagement of the fan as needed. This arrangement allows the engine to operate efficiently across different load conditions, enhancing overall performance and durability.

Connection to the Fan Hub

The fan hub is another component that relies on the spindle for its function. The hub is the central part of the fan to which the blades are attached, and it is mounted on the spindle. The spindle’s precise engineering ensures that the hub can rotate smoothly, distributing air evenly across the engine’s cooling fins. This even distribution is vital for effective heat dissipation, preventing overheating and ensuring the engine operates within safe temperature ranges.

In summary, the part 3024660 Fan Spindle plays a significant role in the coordination and efficiency of the drive, fan, fan drive arrangement, and fan hub within engine systems. Its reliable operation is essential for the overall performance and longevity of the engine.

Conclusion

The Cummins 3024660 Fan Spindle is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient heat dissipation and maintaining optimal engine temperatures. Its robust design, compatibility with various engine configurations, and integral role in the engine’s cooling and air management systems highlight its importance in enhancing engine performance and reliability.

References

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.