This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

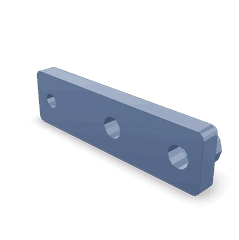

The Exhaust Outlet Connection Brace, identified by part number 5441175, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in the realm of heavy-duty trucks. This brace is integral to the exhaust system, ensuring both structural stability and efficient exhaust flow. Cummins, known for its robust and reliable engine components, provides this part as a solution to enhance the performance and longevity of heavy-duty truck exhaust systems 1.

Function and Operation

The Exhaust Outlet Connection Brace operates within the exhaust system by connecting the exhaust manifold to the turbocharger or the exhaust pipe. It plays a role in maintaining the structural integrity of the exhaust system by providing a stable connection point. This stability is crucial for withstanding the high temperatures and pressures generated during engine operation. Additionally, the brace facilitates efficient exhaust flow, which is vital for optimal engine performance and emissions control 2.

Purpose of the Exhaust Outlet Connection Brace

The specific role of the Exhaust Outlet Connection Brace in a truck’s operation is multifaceted. It contributes to exhaust management by ensuring a secure and stable connection between critical components of the exhaust system. This stability helps in maintaining the alignment and integrity of the exhaust path, which is important for efficient exhaust gas evacuation. Furthermore, by ensuring a smooth and unobstructed exhaust flow, the brace indirectly supports overall engine performance, including power output and fuel efficiency 3.

Key Features

The Exhaust Outlet Connection Brace is characterized by several key features that enhance its functionality. It is typically made from high-strength materials, such as cast iron or steel, to withstand the harsh conditions of the exhaust system. The design of the brace includes precise fitting and alignment features to ensure a secure connection. Additionally, it may incorporate heat-resistant coatings or treatments to protect against the extreme temperatures encountered in the exhaust system.

Benefits

The advantages provided by the Exhaust Outlet Connection Brace include improved durability due to its robust material composition and design. Enhanced exhaust efficiency is another benefit, as the brace ensures a smooth and unobstructed exhaust flow. This can contribute to reduced emissions by allowing the exhaust system to operate more efficiently. Furthermore, the brace’s role in maintaining structural integrity can lead to a longer service life for the exhaust system components.

Installation Considerations

Proper installation of the Exhaust Outlet Connection Brace is important to ensure its effectiveness and longevity. Key steps include ensuring the surfaces are clean and free of debris before installation, using the correct torque specifications for fastening, and verifying the alignment of the exhaust components. Attention to these details can help prevent common installation issues and ensure the brace functions as intended.

Troubleshooting Common Issues

Common problems associated with the Exhaust Outlet Connection Brace may include leaks in the exhaust system, which can be caused by improper installation or wear and tear over time. Troubleshooting steps involve inspecting the connections for signs of damage or misalignment, checking for gasket integrity, and ensuring all fasteners are tightened to the manufacturer’s specifications. Addressing these issues promptly can help maintain the efficiency and safety of the exhaust system.

Maintenance Tips

Routine maintenance practices for the Exhaust Outlet Connection Brace include regular inspection for signs of wear, corrosion, or damage. Cleaning the brace and surrounding components to remove any buildup that could affect performance is also recommended. Additionally, ensuring that all connections are secure and properly torqued during routine maintenance checks can help prevent issues related to exhaust leaks or structural instability.

Compatibility and Applications

The Exhaust Outlet Connection Brace is designed for use in specific types of trucks and engines. Compatibility information, including any specific models or series for which this part is intended, should be consulted to ensure proper fit and function. This information is crucial for maintaining the performance and reliability of the exhaust system in heavy-duty applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency. Cummins’ commitment to excellence is reflected in its extensive portfolio of parts and services designed to meet the demanding requirements of heavy-duty truck applications.

Exhaust Outlet Connection Brace (Part 5441175) in Cummins Engines

The Exhaust Outlet Connection Brace, identified by part number 5441175, is a critical component in the exhaust system of various Cummins engines. This part is designed to provide structural support and stability to the exhaust outlet connection, ensuring that the exhaust system remains securely attached to the engine.

Application in Cummins Engines

QSB6.7 M CM2250

The QSB6.7 M CM2250 engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Exhaust Outlet Connection Brace in this engine plays a vital role in maintaining the integrity of the exhaust system under high operational stresses. It helps to prevent misalignment and potential damage to the exhaust components, thereby contributing to the overall durability and performance of the engine.

Other Cummins Engines

While the specific application of the Exhaust Outlet Connection Brace in the QSB6.7 M CM2250 has been highlighted, it is important to note that this part is also compatible with other Cummins engines. The design and functionality of the brace remain consistent across various engine models, ensuring that it provides the necessary support and stability in different applications. This versatility makes it a valuable component for maintaining the exhaust system’s integrity in a wide range of Cummins engines.

Role of Part 5441175 Exhaust Outlet Connection Brace in Engine Systems

The Exhaust Outlet Connection Brace, identified by part number 5441175, is an integral component in the assembly and functionality of engine systems. This brace serves to reinforce the connection between the exhaust manifold and the exhaust pipe, ensuring a secure and stable link.

In the context of engine systems, the brace plays a significant role in maintaining the structural integrity of the exhaust system. It helps to absorb and distribute the vibrations and stresses that occur during engine operation, which are particularly pronounced at the connection point between the exhaust manifold and the exhaust pipe.

Furthermore, the brace contributes to the overall efficiency of the exhaust system by ensuring that the connection remains tight and sealed. This is important for preventing exhaust leaks, which can lead to decreased engine performance and increased emissions.

Additionally, the brace aids in aligning the exhaust components properly, which is essential for the smooth flow of exhaust gases. Proper alignment reduces the risk of backpressure, which can adversely affect engine performance and fuel efficiency.

Conclusion

In summary, the Exhaust Outlet Connection Brace is a key component that enhances the durability, performance, and efficiency of engine systems by providing a robust and reliable connection between critical exhaust components.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.