5365770

Exhaust Gas Recirculation Module

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Exhaust Gas Recirculation (EGR) Module 5365770 by Cummins is designed to enhance the performance and environmental compliance of commercial truck engines. This module is integral to the engine’s emission control system, facilitating the recirculation of a portion of the exhaust gas back into the intake system. By doing so, it plays a role in reducing nitrogen oxides (NOx) emissions, which are a significant concern in the trucking industry due to their environmental impact 3.

Basic Concepts of Exhaust Gas Recirculation

Exhaust Gas Recirculation (EGR) is a technique used in internal combustion engines to reduce the combustion temperature and, consequently, the formation of nitrogen oxides. The process involves redirecting a controlled amount of exhaust gas back into the intake manifold. This dilution of the intake charge with inert exhaust gas lowers the peak combustion temperature, which in turn reduces the formation of NOx 2.

Role of the EGR Module in Truck Operation

The EGR Module 5365770 by Cummins is designed to integrate seamlessly with the engine’s operation. It works in conjunction with the engine control unit (ECU) to monitor and adjust the flow of recirculated exhaust gas. This module interacts with various engine components, including the intake and exhaust systems, to ensure optimal performance. By regulating the amount of exhaust gas recirculated, the module helps maintain engine efficiency while reducing emissions. Its role is particularly significant in high-load and high-temperature operating conditions, where NOx formation is most pronounced 3.

Key Features of the Cummins EGR Module 5365770

The Cummins EGR Module 5365770 is characterized by several key features that enhance its functionality and durability. These include a robust design that withstands the harsh conditions of commercial truck operation, the use of high-quality materials to ensure longevity, and advanced technological features that improve performance. The module is engineered to provide precise control over the EGR process, ensuring that the right amount of exhaust gas is recirculated under varying engine loads and speeds 1.

Benefits of Using the Cummins EGR Module 5365770

The use of the Cummins EGR Module 5365770 offers several advantages. It contributes to improved fuel efficiency by optimizing the combustion process. Additionally, it plays a role in significantly reducing harmful emissions, particularly NOx, which is a major contributor to air pollution. Compliance with environmental regulations is another benefit, as the module helps trucks meet the stringent emissions standards set by regulatory bodies. Furthermore, the module’s design and construction ensure durability and reliability, reducing the need for frequent maintenance and replacements 3.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the Cummins EGR Module 5365770, regular maintenance and troubleshooting are recommended. Common issues may include blockages in the EGR passages, malfunctioning sensors, or electronic control problems. Diagnostic procedures should be performed using appropriate tools and following manufacturer guidelines. Regular inspections and cleaning of the EGR system components can prevent buildup and ensure smooth operation. Additionally, keeping the module and its associated sensors in good working condition is crucial for maintaining engine performance and emissions compliance 3.

Integration with Engine Management Systems

The Cummins EGR Module 5365770 is designed to interface with modern engine management systems, including electronic control units (ECUs) and sensor networks. This integration allows for precise control over the exhaust gas recirculation process. The module communicates with the ECU to adjust the EGR valve position based on real-time data from various sensors, such as engine load, temperature, and exhaust gas composition. This ensures that the EGR system operates efficiently under a wide range of driving conditions, contributing to both performance and emissions goals 3.

Environmental Impact and Regulatory Compliance

The environmental benefits of using EGR technology are significant. By reducing NOx emissions, the Cummins EGR Module 5365770 helps mitigate the environmental impact of commercial trucks. This reduction in emissions contributes to improved air quality and compliance with environmental regulations. The module is engineered to meet or exceed the emissions standards set by regulatory agencies, ensuring that trucks equipped with this technology can operate in regions with strict emissions controls 3.

Technological Innovations in EGR Systems

Recent technological advancements in EGR systems have focused on enhancing performance, reliability, and efficiency. Cummins has been at the forefront of these innovations, introducing features such as improved EGR valve designs, advanced sensor technologies, and enhanced control algorithms. These advancements ensure that the EGR Module 5365770 not only meets current emissions standards but also provides a foundation for future improvements in commercial truck engine technology 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the automotive and engine manufacturing industry. The company is committed to innovation and sustainability, continually developing new technologies to improve engine performance, reduce emissions, and enhance fuel efficiency. Cummins’ extensive product portfolio includes a wide range of engines and components designed for various applications, from on-highway trucks to off-highway equipment and power generation systems 1.

Cummins Exhaust Gas Recirculation Module 5365770 Compatibility

The Cummins Exhaust Gas Recirculation (EGR) Module part number 5365770 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and compliance with emissions standards. This part is engineered to work with the following engines:

ISF2.8 CM2220 F129

This specific module is compatible with the ISF2.8 CM2220 F129 engine, providing a crucial component in the EGR system. The EGR module plays a vital role in reducing nitrogen oxide (NOx) emissions by recirculating a portion of the engine’s exhaust gas back to the intake air. This process lowers the combustion temperature, thereby reducing NOx formation 3.

Other Cummins Engines

While the focus here is on the ISF2.8 CM2220 F129 engine, it is important to note that the Cummins EGR Module 5365770 is also compatible with a variety of other Cummins engines. This compatibility extends across different engine series and models, ensuring that the module can be utilized in a broad range of applications. The design and functionality of the module are consistent across these engines, providing a reliable and efficient solution for EGR needs 3.

The integration of the EGR module into these engines is straightforward, thanks to its standardized design and fitment. Cummins has ensured that the installation process is user-friendly, allowing for quick and easy replacement or installation of the EGR module. This ease of use is critical for maintaining engine performance and ensuring that the EGR system operates effectively 3.

Role of Part 5365770 Exhaust Gas Recirculation Module in Engine Systems

The Exhaust Gas Recirculation (EGR) Module, identified by part number 5365770, is integral to the operation of modern engine systems. Its primary function is to reduce nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold. This process dilutes the oxygen concentration in the intake charge, thereby lowering combustion temperatures and reducing the formation of NOx 2.

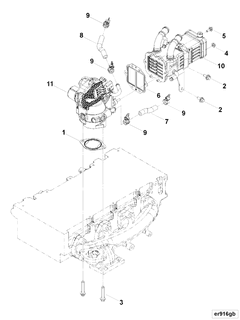

Integration with Engine Components

-

Intake Manifold: The EGR module is strategically positioned to feed recirculated exhaust gases into the intake manifold. This mixture then travels through the intake tract and into the combustion chamber, where it combines with fresh air and fuel.

-

Exhaust Manifold: Post-combustion, the exhaust gases exit the engine through the exhaust manifold. A portion of these gases is redirected by the EGR module rather than being expelled through the tailpipe.

-

Throttle Body: The recirculated exhaust gases interact with the airstream controlled by the throttle body. This ensures a consistent and regulated flow of the gas mixture into the engine.

-

Combustion Chamber: Within the combustion chamber, the recirculated exhaust gases mix with the air-fuel mixture. The reduced oxygen concentration leads to lower peak temperatures during combustion, effectively minimizing NOx production.

-

EGR Valve: The EGR module often includes or is closely associated with the EGR valve, which controls the flow rate of recirculated exhaust gases. This valve operates based on signals from the engine control unit (ECU), ensuring optimal recirculation rates under varying engine loads and speeds.

-

Catalytic Converter: Although the EGR module’s primary role is emission reduction at the source, the catalytic converter further processes the exhaust gases to convert any remaining pollutants into less harmful substances before they are released into the atmosphere.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the EGR module’s operation accordingly. It ensures that the recirculation process is optimized for both performance and emissions compliance.

By effectively managing the recirculation of exhaust gases, part 5365770 contributes to a more efficient and environmentally friendly engine operation 3.

Conclusion

The Cummins Exhaust Gas Recirculation Module 5365770 is a critical component in modern commercial truck engines, designed to reduce NOx emissions and improve engine efficiency. Its integration with engine management systems ensures precise control over the EGR process, contributing to both performance and emissions compliance. Regular maintenance and troubleshooting are essential to ensure the module’s optimal performance and longevity. With its robust design and advanced technological features, this part plays a significant role in enhancing the environmental compliance and operational efficiency of commercial trucks 3.

-

Reza N. Jazar, Vehicle Dynamics: Theory and Application, Springer, 2017.

↩ ↩ -

Alessandro Ferrari and Pietro Pizzo, Injection Technologies: Mixture Formation Strategies, SAE International, 2022.

↩ ↩ ↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Jones Bartlett Learning, 2016.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.