This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

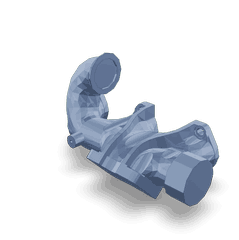

The Cummins 5297137 Exhaust Manifold is a component designed for heavy-duty trucks, playing a role in the engine system by managing the flow of exhaust gases from the engine cylinders to the exhaust system 2. This part is engineered to enhance engine performance, efficiency, and durability under demanding conditions typical of heavy-duty applications.

Basic Concepts of Exhaust Manifolds

An exhaust manifold is a part of the engine system that collects exhaust gases from the engine’s cylinders and directs them into the exhaust system. It contributes to the efficient expulsion of exhaust gases, which is important for maintaining engine performance and reducing emissions 1. The design and material of the manifold can influence engine efficiency, durability, and the overall management of exhaust gases.

Purpose of the Cummins 5297137 Exhaust Manifold

The Cummins 5297137 Exhaust Manifold is specifically designed to facilitate the efficient flow of exhaust gases away from the engine. By ensuring that exhaust gases are directed smoothly and without restriction, it contributes to the engine’s ability to operate efficiently. This part is integral to maintaining the engine’s performance and longevity in heavy-duty truck applications.

Key Features

The Cummins 5297137 Exhaust Manifold is constructed from high-quality materials, ensuring durability and resistance to the high temperatures and pressures encountered in heavy-duty truck engines. Its design incorporates features that enhance its performance, such as precise engineering to ensure optimal flow of exhaust gases and robust construction to withstand the rigors of heavy-duty use.

Benefits

The use of the Cummins 5297137 Exhaust Manifold offers several advantages. It contributes to improved engine efficiency by ensuring that exhaust gases are expelled effectively, which can lead to better fuel economy. Additionally, its design helps in reducing emissions by facilitating a more complete expulsion of exhaust gases. The durability of the manifold ensures long-term performance and reliability in demanding applications.

Installation Considerations

Proper installation of the Cummins 5297137 Exhaust Manifold is important for ensuring its effectiveness and longevity. Installation procedures should follow manufacturer guidelines to ensure that the manifold is securely and correctly fitted. This may involve the use of specific tools or prerequisites to ensure a proper fit and seal.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 5297137 Exhaust Manifold is important for ensuring its continued performance and durability. This includes checking for signs of wear or damage and ensuring that all connections are secure. Common issues may include leaks or blockages, which can be addressed through inspection and repair or replacement as necessary.

Performance Impact

The Cummins 5297137 Exhaust Manifold plays a role in the overall performance of the truck by contributing to efficient engine operation. Its impact can be seen in aspects such as fuel efficiency, power output, and emission levels. By ensuring the smooth flow of exhaust gases, it helps maintain engine performance under a variety of operating conditions.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its high-quality engine and component manufacturing. With a history of innovation and commitment to quality, Cummins has built a reputation for producing reliable and efficient parts that meet the demands of heavy-duty applications.

Role of Part 5297137 Exhaust Manifold in Engine Systems

The exhaust manifold, specifically part 5297137, is integral to the efficient operation of an engine system. It serves as a conduit that collects exhaust gases from the engine’s cylinders and directs them into the exhaust system 2.

When the engine’s pistons complete their power stroke, they expel exhaust gases through the exhaust ports. These gases are then channeled into the manifold, where they merge before being expelled through the exhaust pipe. The design of the manifold ensures that the flow of gases is smooth and uninterrupted, which is important for maintaining engine performance and efficiency.

The manifold is typically made from cast iron or stainless steel to withstand the high temperatures and pressures of the exhaust gases. Its connection to the engine is secured with manifold gaskets, which create a seal to prevent leaks.

In addition to its primary function, the manifold also plays a role in the engine’s thermal management. By routing hot exhaust gases away from the engine block, it helps to maintain optimal operating temperatures. This is particularly important in high-performance engines where thermal efficiency can significantly impact overall performance.

The integration of the manifold with the catalytic converter is another key aspect. The converter is positioned downstream of the manifold and is responsible for reducing harmful emissions by converting toxic gases into less harmful substances. The manifold’s design must facilitate this process by ensuring a consistent flow of exhaust gases to the converter.

Furthermore, the manifold’s connection to the turbocharger (if present) is vital for turbocharged engines. The turbocharger uses the energy from the exhaust gases to compress the intake air, thereby increasing engine power. The manifold must be designed to efficiently transfer this energy while minimizing backpressure, which can adversely affect engine performance.

Conclusion

In summary, the Cummins 5297137 Exhaust Manifold is a fundamental component that ensures the proper functioning of the engine’s exhaust system. Its role in collecting, directing, and managing exhaust gases is important for maintaining engine efficiency, performance, and compliance with emissions regulations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.