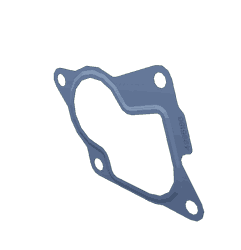

4995186

Exhaust Outlet Connection Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4995186 Exhaust Outlet Connection Gasket by Cummins is a component designed to ensure the efficient operation of commercial trucks. This gasket plays a role in maintaining the integrity of the exhaust system by sealing the connection between the exhaust manifold and the exhaust pipe. Its proper function is significant for the overall performance and efficiency of the truck’s engine 1.

Basic Concepts of Exhaust Outlet Connection Gaskets

An Exhaust Outlet Connection Gasket is a sealing component used in the exhaust system of vehicles. Its primary function is to create a tight seal between the exhaust manifold and the exhaust pipe. This seal helps prevent exhaust gases from leaking, which can lead to reduced engine performance, increased emissions, and potential safety hazards. By ensuring a secure connection, the gasket contributes to the overall efficiency and reliability of the truck’s exhaust system 2.

Purpose of the 4995186 Exhaust Outlet Connection Gasket

The 4995186 Exhaust Outlet Connection Gasket is specifically designed to seal the connection between the exhaust manifold and the exhaust pipe in Cummins engines. This gasket plays a role in preventing exhaust leaks, which can cause a loss of engine power, increased fuel consumption, and higher emissions. By maintaining a secure seal, the gasket helps ensure that exhaust gases are properly directed away from the engine, contributing to the truck’s overall performance and efficiency 3.

Key Features

The 4995186 Exhaust Outlet Connection Gasket features a robust material composition that enhances its durability and performance. It is designed to withstand high temperatures and pressures typical of commercial truck exhaust systems. The gasket’s precise design ensures a snug fit, providing an effective seal that resists wear and tear over time. These features contribute to its reliability and longevity in demanding applications 4.

Benefits

The 4995186 Exhaust Outlet Connection Gasket offers several benefits, including improved sealing efficiency, reduction in exhaust leaks, and contribution to overall engine performance. By preventing leaks, the gasket helps maintain engine efficiency, reduce emissions, and enhance the truck’s reliability. Its durable construction ensures long-lasting performance, making it a valuable component for commercial truck operators 5.

Installation Process

Installing the 4995186 Exhaust Outlet Connection Gasket involves several steps to ensure a secure fit. Begin by cleaning the mating surfaces of the exhaust manifold and exhaust pipe to remove any debris or old gasket material. Place the gasket onto the exhaust manifold, ensuring it is properly aligned. Connect the exhaust pipe to the manifold, using the appropriate tools to tighten the connection without over-torquing. Verify the seal by checking for any signs of leaks once the engine is running 6.

Common Issues and Troubleshooting

Common issues associated with Exhaust Outlet Connection Gaskets include leaks and deterioration over time. Signs of a failing gasket may include unusual exhaust noises, reduced engine performance, or increased emissions. To troubleshoot these problems, inspect the gasket for signs of wear, such as cracks or warping. If any issues are detected, replace the gasket to restore the seal and ensure proper exhaust system function 7.

Maintenance Tips

To maintain the 4995186 Exhaust Outlet Connection Gasket, regular inspections are recommended. Check the gasket during routine maintenance intervals for signs of wear or damage. Look for cracks, warping, or any other indications that the gasket may be failing. If any issues are found, consider replacing the gasket to prevent exhaust leaks and maintain engine performance. Keeping the mating surfaces clean and free of debris will also help extend the gasket’s lifespan 8.

Compatibility and Application

The 4995186 Exhaust Outlet Connection Gasket is compatible with various Cummins engines and is applied in different truck models. Its design ensures a proper fit and effective seal in these applications, contributing to the reliable operation of the exhaust system 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various industries, including transportation, construction, and agriculture 10.

Exhaust Outlet Connection Gasket Fitment for Cummins Engines

The Exhaust Outlet Connection Gasket, part number 4995186, manufactured by Cummins, is a critical component in ensuring the integrity of the exhaust system. This gasket is designed to fit seamlessly with a variety of Cummins engines, providing a reliable seal between the exhaust outlet and the connected components. Below is a detailed description of how this gasket fits with the specified engines:

D4.0 CM2620 D103B, F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, F3.8 F102, F4.5 CM2620 F139B, F4.5 CM2620 F141C

These engines, which include both the D4.0 and F3.8 series, are part of Cummins’ mid-range power offerings. The Exhaust Outlet Connection Gasket is engineered to fit the specific exhaust outlet configurations of these engines, ensuring a tight seal that prevents exhaust leaks. This is crucial for maintaining optimal engine performance and efficiency 11.

ISF2.8 CM2220 F129, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF3.8 CM2350 F109

The ISF series engines, known for their reliability in heavy-duty applications, also benefit from the precise fit of the Exhaust Outlet Connection Gasket. This gasket is designed to accommodate the unique exhaust outlet dimensions of the ISF2.8 and ISF3.8 models, ensuring a secure and leak-free connection 12.

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F114, QSF3.8 CM2350 F107, QSF3.8 CM2880 F112

The QSF series engines, which are part of Cummins’ high-performance lineup, require a gasket that can handle the rigors of their demanding applications. The Exhaust Outlet Connection Gasket is crafted to fit these engines perfectly, providing a robust seal that withstands the high pressures and temperatures of the exhaust system 13.

R2.8 CM2220 R101B

The R series engines, known for their versatility and efficiency, also utilize the Exhaust Outlet Connection Gasket. This gasket is designed to fit the specific exhaust outlet of the R2.8 model, ensuring a reliable seal that supports the engine’s performance and longevity 14.

Role of Part 4995186 Exhaust Outlet Connection Gasket in Engine Systems

The Exhaust Outlet Connection Gasket, part number 4995186, is an essential component in ensuring the integrity and efficiency of various engine systems. This gasket is specifically designed to create a secure seal between the exhaust outlet and the connection device, preventing exhaust leaks that could lead to performance issues and increased emissions 15.

Integration with Aftertreatment Systems

In aftertreatment systems, the Exhaust Outlet Connection Gasket plays a significant role by maintaining a tight seal between the exhaust outlet and the aftertreatment device. This seal is vital for the proper functioning of components such as Diesel Particulate Filters (DPFs) and Selective Catalytic Reduction (SCR) systems. A well-sealed connection ensures that exhaust gases pass through these aftertreatment devices efficiently, allowing them to effectively reduce emissions and comply with environmental regulations 16.

Engine Installation Kit

When included in an engine installation kit, the Exhaust Outlet Connection Gasket ensures that the exhaust system is correctly sealed during the installation process. This is particularly important during the initial setup or when performing maintenance on the engine. A proper seal prevents exhaust gases from escaping, which can otherwise lead to decreased engine performance and increased wear on other components 17.

Turbocharger and Turbocharger Gasket Kit

In turbocharger systems, the Exhaust Outlet Connection Gasket is often part of a turbocharger gasket kit. It ensures a secure connection between the exhaust outlet and the turbocharger. This seal is essential for maintaining the turbocharger’s efficiency, as any leak can result in a loss of boost pressure, reducing the engine’s power output and fuel efficiency 18.

Upper Engine Gasket Kit

The Exhaust Outlet Connection Gasket is also a component of the upper engine gasket kit. In this context, it ensures that the exhaust system is properly sealed at the point where it connects to the engine block or cylinder head. This is important for maintaining the overall integrity of the engine’s upper section, preventing exhaust gases from entering areas where they could cause damage or reduce performance 19.

Product Installation

During product installation, whether it’s a new engine or an aftermarket upgrade, the Exhaust Outlet Connection Gasket must be correctly installed to ensure the exhaust system operates as designed. Proper installation of this gasket is a key step in achieving optimal engine performance and longevity 20.

Conclusion

In summary, the Exhaust Outlet Connection Gasket, part number 4995186, is a vital component in various engine systems, ensuring that exhaust gases are properly contained and directed through the system. Its role in creating a secure seal is fundamental to the efficient operation of aftertreatment devices, turbochargers, and the overall engine installation process.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). D4.0 CM2620 D103B, F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, F3.8 F102, F4.5 CM2620 F139B, F4.5 CM2620 F141C. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). ISF2.8 CM2220 F129, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF3.8 CM2350 F109. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F114, QSF3.8 CM2350 F107, QSF3.8 CM2880 F112. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). R2.8 CM2220 R101B. Retrieved from Cummins Official Website.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.