4067022

Exhaust Manifold Gasket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Exhaust Manifold Gasket, specifically Part #4067022 by Cummins, is a vital component in the engine systems of heavy-duty trucks. Cummins, a renowned manufacturer in the automotive industry, produces this gasket to ensure reliable and efficient engine performance. This gasket is designed to meet the demanding requirements of heavy-duty applications, providing a secure seal between the exhaust manifold and the engine block 1.

Basic Concepts

An Exhaust Manifold Gasket serves as a seal between the exhaust manifold and the engine block. Its primary function is to prevent exhaust gases from leaking into the engine compartment, ensuring that these gases are directed efficiently through the exhaust system. This gasket operates under high temperatures and pressures, making its material and design critical for maintaining engine efficiency and safety 2.

Purpose of the Exhaust Manifold Gasket

The Exhaust Manifold Gasket plays a role in the operation of a truck by sealing the connection between the exhaust manifold and the engine block. This seal is crucial for maintaining the integrity of the exhaust system, ensuring that exhaust gases are properly channeled away from the engine. By doing so, it contributes to the overall efficiency and performance of the engine, reducing the risk of leaks that could lead to decreased engine performance or potential safety hazards 3.

Key Features

The Exhaust Manifold Gasket is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the extreme temperatures and pressures encountered in heavy-duty truck engines. The design of the gasket ensures a tight and reliable seal, minimizing the risk of leaks. Additionally, it is engineered to be compatible with Cummins engines, ensuring optimal performance and longevity 4.

Benefits

Using the Exhaust Manifold Gasket offers several benefits. It contributes to improved engine efficiency by ensuring a secure seal that prevents exhaust gas leaks. This results in more effective exhaust flow, which can enhance engine performance. Additionally, by maintaining a proper seal, the gasket helps reduce emissions, contributing to a cleaner operating environment. Its durable construction ensures longevity under the high-stress conditions typical in heavy-duty truck operations 5.

Installation and Maintenance

Proper installation of the Exhaust Manifold Gasket is crucial for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to achieve the best seal and performance. Regular maintenance checks are recommended to ensure the gasket remains in good condition. This includes inspecting for signs of wear or damage and replacing the gasket if necessary to prevent potential issues such as leaks or decreased engine performance 6.

Troubleshooting Common Issues

Common problems associated with Exhaust Manifold Gaskets include leaks or failures, which can lead to decreased engine performance and increased emissions. To troubleshoot these issues, it is important to inspect the gasket for signs of wear, damage, or improper installation. Addressing these issues promptly can help maintain engine efficiency and prevent more significant problems from arising 7.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and quality. The company is known for its expertise in producing high-performance engines and components for various applications, including heavy-duty trucks. Cummins’ commitment to quality and performance is evident in its wide range of products, designed to meet the demanding requirements of the automotive industry 8.

Exhaust Manifold Gasket 4067022 Compatibility with Cummins Engines

The Exhaust Manifold Gasket 4067022, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This gasket is crucial for ensuring a proper seal between the exhaust manifold and the engine block, preventing leaks and maintaining optimal performance.

QSK60 Series

The QSK60 series, including the QSK60 G and QSK60G, are high-performance engines known for their reliability and efficiency. The Exhaust Manifold Gasket 4067022 is specifically engineered to fit these engines, providing a tight seal that is essential for maintaining exhaust pressure and preventing leaks. This gasket ensures that the exhaust gases are directed efficiently, contributing to the overall performance and longevity of the engine.

CM2358 and K110

The CM2358 and K110 engines also benefit from the use of the Exhaust Manifold Gasket 4067022. These engines, while differing in some specifications, share a common need for a reliable gasket that can withstand the high temperatures and pressures of the exhaust system. The 4067022 gasket is designed to fit these engines perfectly, ensuring that the exhaust manifold is securely attached to the engine block. This is critical for maintaining the integrity of the exhaust system and preventing any potential damage caused by leaks.

By using the Exhaust Manifold Gasket 4067022, owners of these Cummins engines can be confident that their exhaust systems are properly sealed, contributing to the overall efficiency and performance of their engines.

Role of Part 4067022 Exhaust Manifold Gasket in Engine Systems

The Exhaust Manifold Gasket is an essential component in the assembly and operation of various engine systems. It functions as a seal between the exhaust manifold and the engine block, ensuring that exhaust gases are directed efficiently from the cylinders to the exhaust system without leakage.

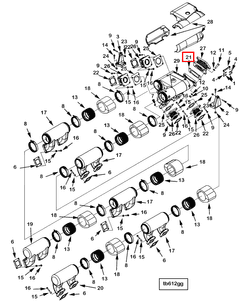

Integration with the Manifold

When the exhaust manifold is bolted to the engine block, the Exhaust Manifold Gasket is placed between these two components. This placement is vital for maintaining a secure seal, which prevents exhaust gases from escaping into the engine compartment. The gasket’s material is designed to withstand high temperatures and pressures, ensuring durability and reliability in this demanding environment.

Interaction with the Exhaust System

The gasket works in conjunction with the exhaust system by ensuring a tight seal that allows exhaust gases to flow smoothly from the manifold into the exhaust pipes. This efficient flow is important for maintaining engine performance and reducing emissions. The gasket helps in minimizing the risk of exhaust leaks, which can lead to decreased engine efficiency and increased emissions.

Role in Turbocharger Kit Installations

In engines equipped with a turbocharger kit, the Exhaust Manifold Gasket plays an additional role. Turbochargers increase the pressure of the exhaust gases, which in turn increases the pressure on the gasket. The gasket must be able to handle these increased pressures without failing, ensuring that the turbocharger operates efficiently and that the engine’s performance is optimized.

Compatibility with Head Quadrant Gasket Kit

The Exhaust Manifold Gasket is often used in conjunction with a head quadrant gasket kit. These gaskets work together to create a comprehensive sealing solution for the engine. The head quadrant gaskets seal the cylinder head to the engine block, while the exhaust manifold gasket seals the manifold to the block. Together, they ensure that both combustion gases and exhaust gases are contained within their respective pathways, contributing to the overall efficiency and reliability of the engine.

Conclusion

In summary, the Exhaust Manifold Gasket is a key component in the engine’s exhaust system, working in harmony with the manifold, exhaust, and turbocharger kit to ensure efficient and safe operation of the engine. Its role in maintaining a secure seal, preventing leaks, and contributing to engine performance and emissions reduction underscores its importance in heavy-duty truck engine systems.

-

Wolf-Henning Schneider, Pistons and Engine Testing, Springer Nature, 2016.

↩ -

Michael Hilgers and Wilfried Achenbach, Vocational Vehicles and Applications, Springer Vieweg, 2021.

↩ -

Hamid Taghavifar and Aref Mardani, Offroad Vehicle Dynamics Analysis Modelling and Optimization, Springer, 2017.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Jones Bartlett Learning, 2016.

↩ -

Cummins Inc., QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc., QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc., QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩ -

Cummins Inc., QSV81 and QSV91 CM700 Generator Set, Bulletin Number 4021313, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.